Winding spool used for cable winding

A winding reel and wire winding technology, which is applied in the direction of circuit, coil manufacturing, electrical components, etc., can solve the problem of transformer core window size and oil tank size increase, coil radial and axial size are too large, winding staff skills Require high-level problems to achieve the effect of saving labor, reducing procedures and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

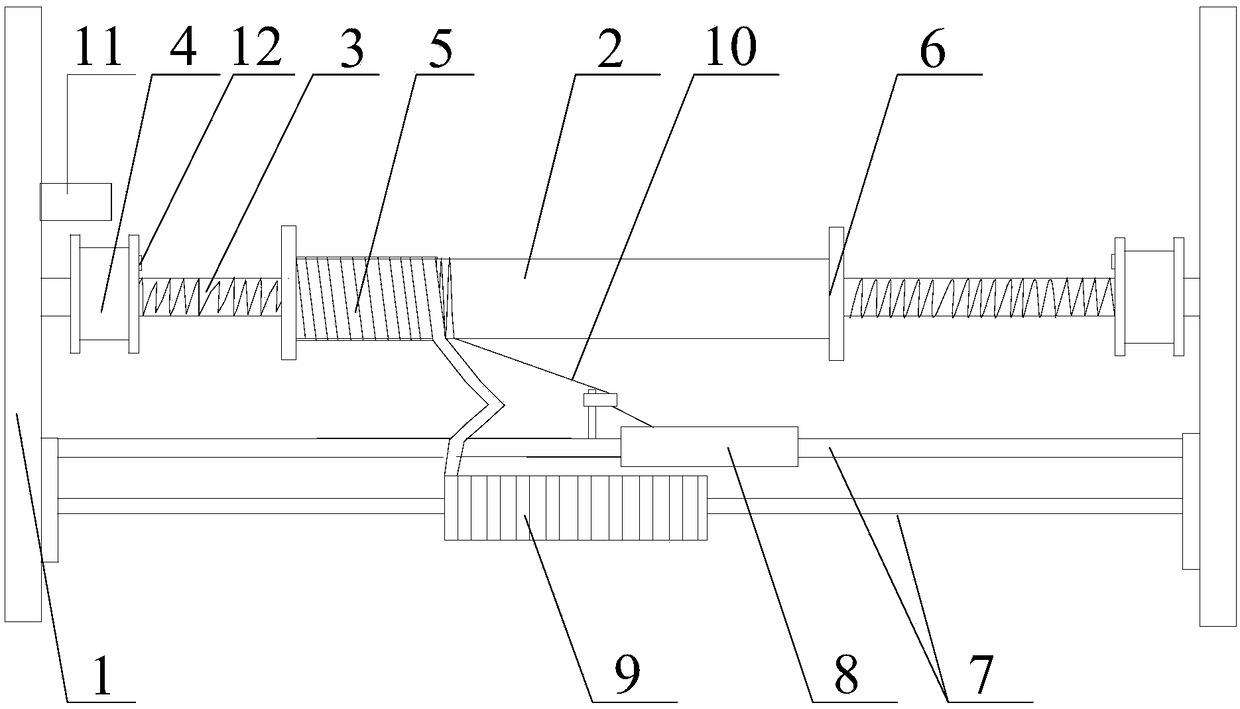

[0027] like figure 1 As shown, the winding reel used for cable winding in the present invention includes a frame, and the frame includes two supporting columns 1 parallel to each other, and a winding drum 2 is arranged between the two supporting columns 1, so that The inner wall of the bobbin 2 is provided with an internal thread, and also includes two round rods 3 equal to the axial length of the bobbin 2, and one end of the two round rods 3 passes through the two end faces of the bobbin 2 respectively. Located inside the bobbin 2, the other end is respectively connected with two driving motors 4 arranged on the support column 1, and the shafts of the two round rods 3 are respectively provided with external threads with the same direction, and the external threads are all connected with the internal threads. The threads are matched with each other; a controller is also included, the controller is respectively connected with two drive motors 4, when the controller controls the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com