Method for spraying tin on pole plate

A plate and grid technology, which is applied in the field of tin plating on the plate, can solve problems such as uneven tin plating, and achieve the effect of avoiding waste and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

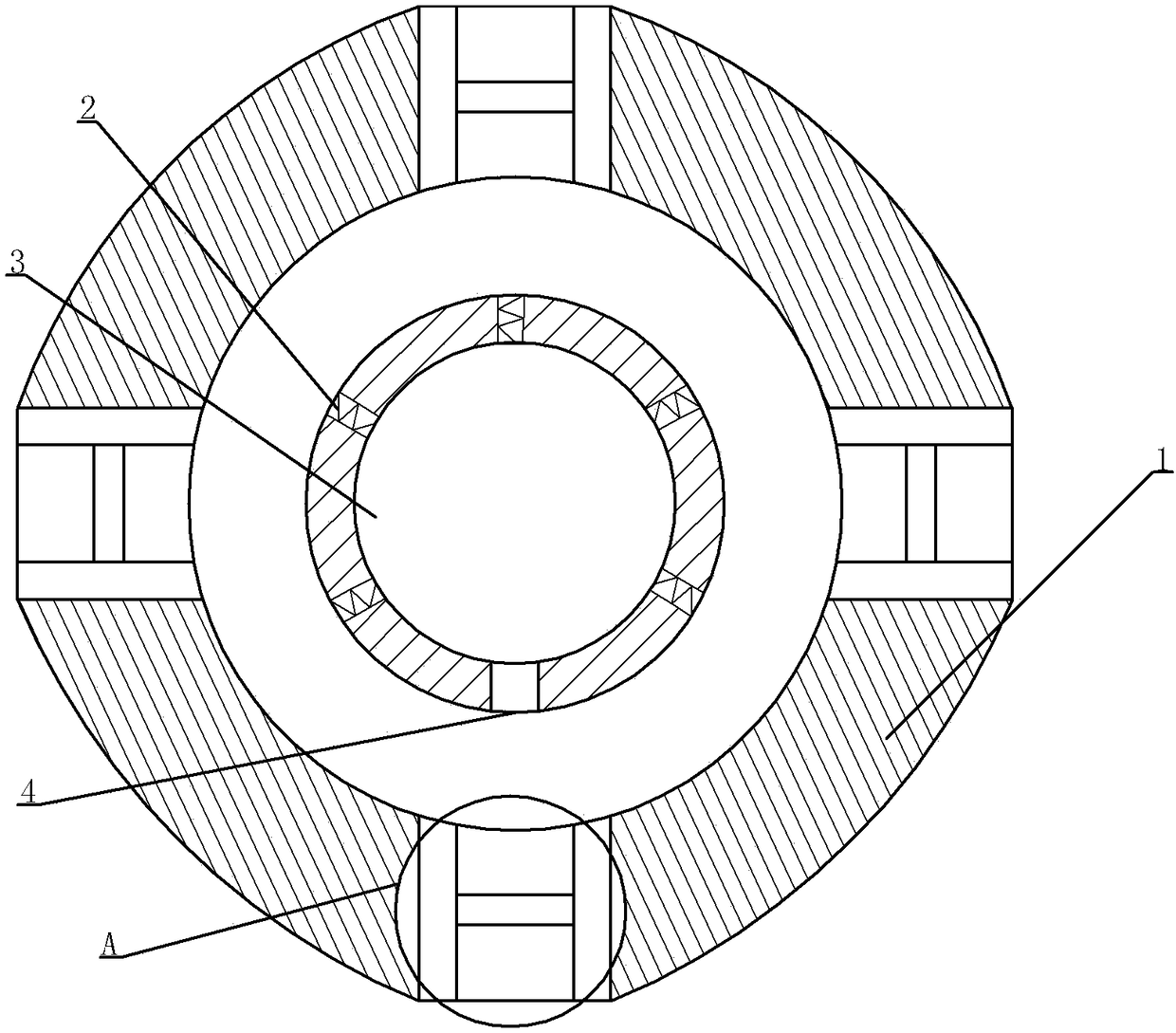

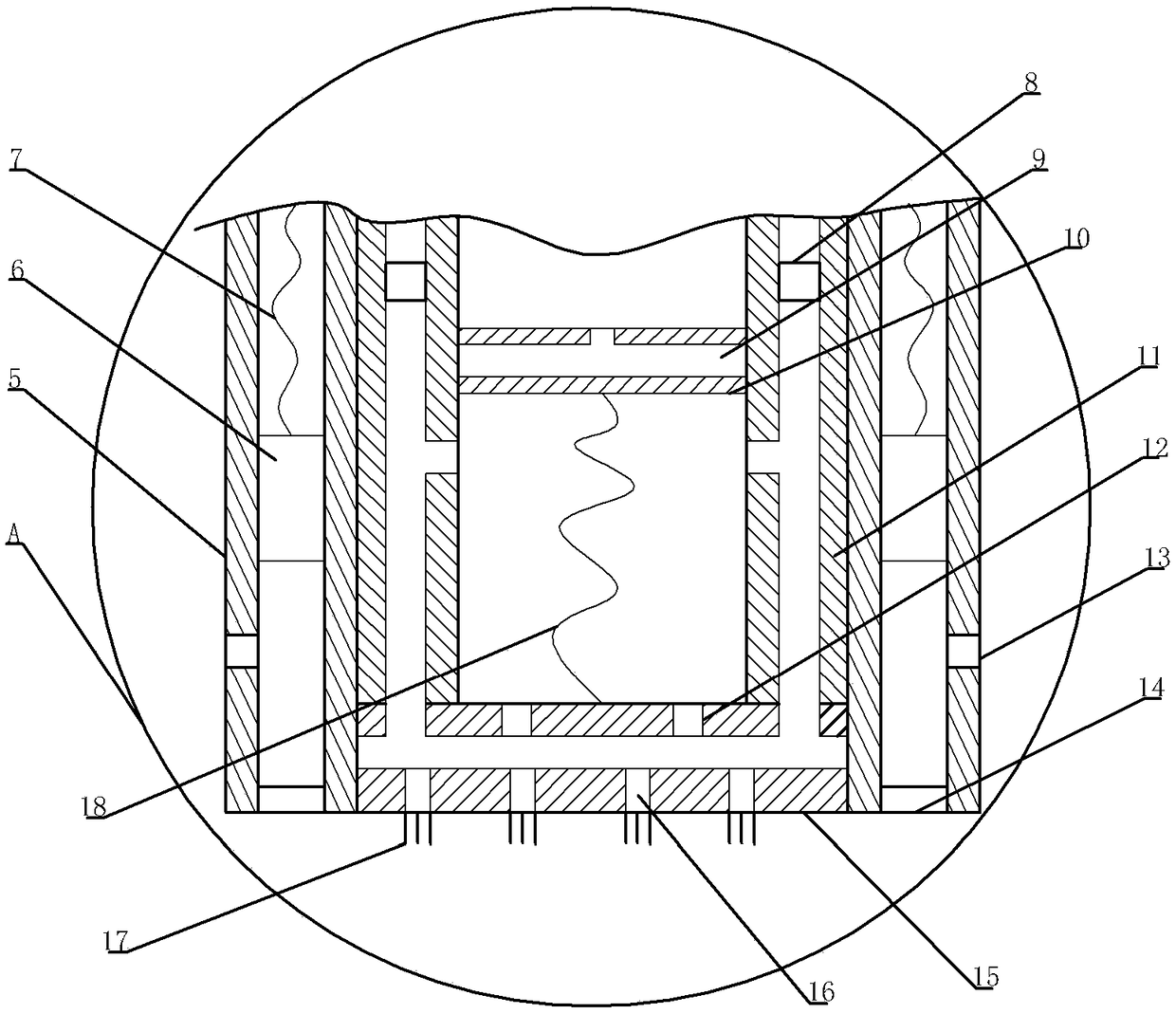

[0024] as attached figure 1 And attached figure 2 As shown, a tin shower device includes a frame, a heating barrel 3 and a storage barrel 1 sleeved outside the heating barrel 3. The distance between the heating barrel 3 and the storage barrel 1 is 18 cm, and the heating barrel 3 is connected to the storage barrel 1 in rotation. , the heating barrel 3 and the storage barrel 1 are placed horizontally and connected with the frame in rotation. The frame is fixed with a first motor that drives the heating barrel 3 to rotate, and the frame is fixed with a second motor that drives the storage barrel 1 to rotate. The second motor is a stepping motor and the stepping motor rotates once every 30s. is 90°. The heating barrel 3 is provided with an opening 4 and five spiral washers for heating the heating barrel 3 . The spiral electric coil 2 can heat the heating barrel 3, and the first motor drives the heating barrel 3 to rotate so that the tin block in the heating barrel 3 is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com