Patents

Literature

40results about How to "No sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

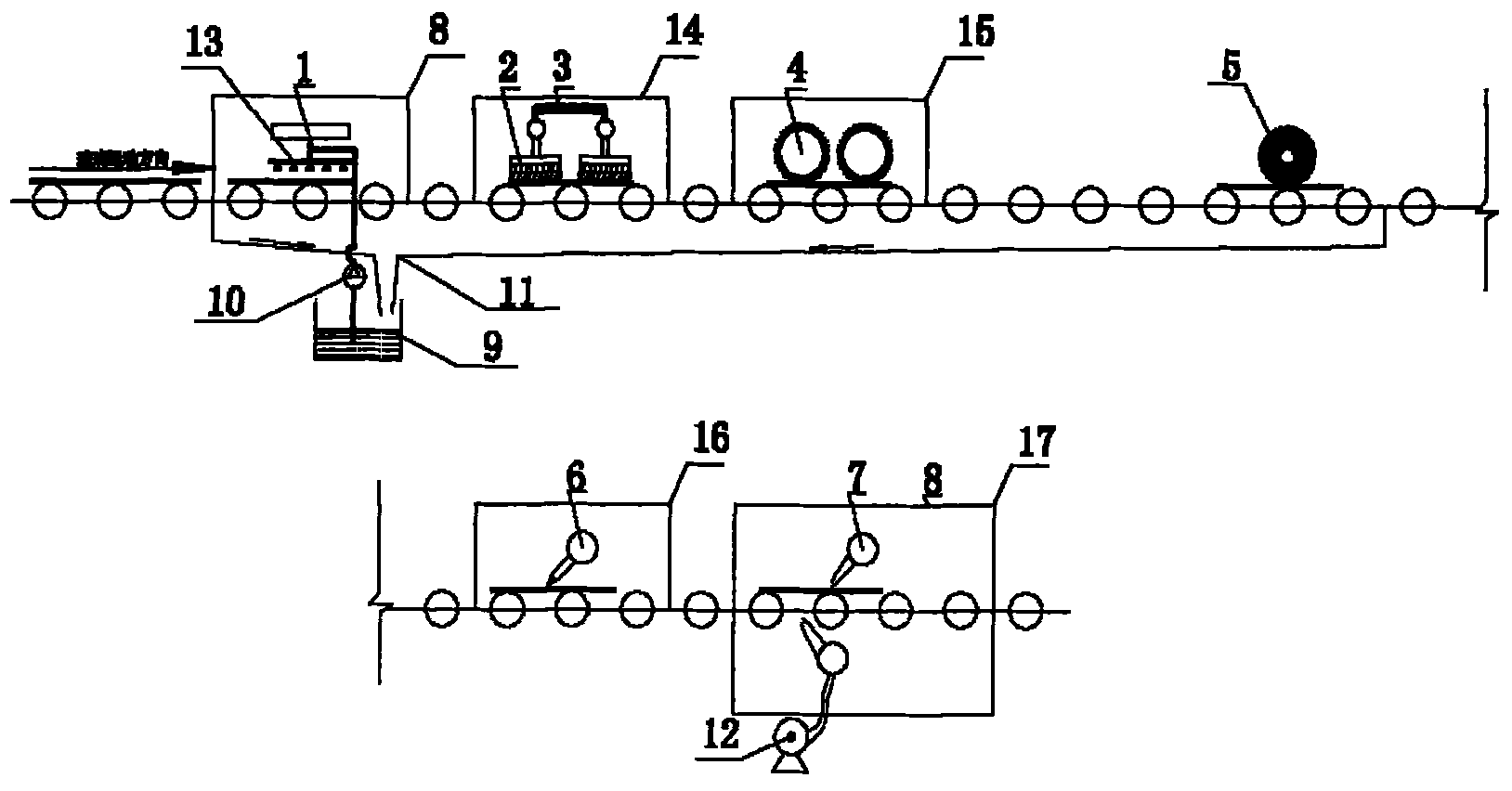

Mildew-proof treatment method for flat glass

The invention discloses a mildew-proof treatment method for flat glass, which is realized through an operation process of a glass roller bed and comprises the following steps of: (1) spraying a mildew-proof solution to the flat glass subjected to cutting and edge breaking-off; (2) sequentially washing the flat glass sprayed with the mildew-proof solution in the step (1) by a disk brush and a roller bush, then, immersing the flag glass in the mildew-proof solution completely, and standing for 2-10min; (3) delivering the flat glass immersed with the mildew-proof solution in the step (2) into sponge compression rollers so as to squeeze away the mildew-proof solution on the surface of the flat glass; (4) carrying out jet-cleaning on the flat glass coming out from the sponge compression rollers by using a high-pressure water pipe; and (5) airing the cleaned flat glass through a high-pressure air knife finally. The treated flat glass has bright and clean surfaces and prolonged mildew-proof period; the mildew-proof solution used in the method is recyclable, and the mildew-proof treatment process is fully closed so that no liquid sputters and the treatment cost is reduced; and the method is suitable for the traditional glass roller bed and is easy to popularize and apply.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

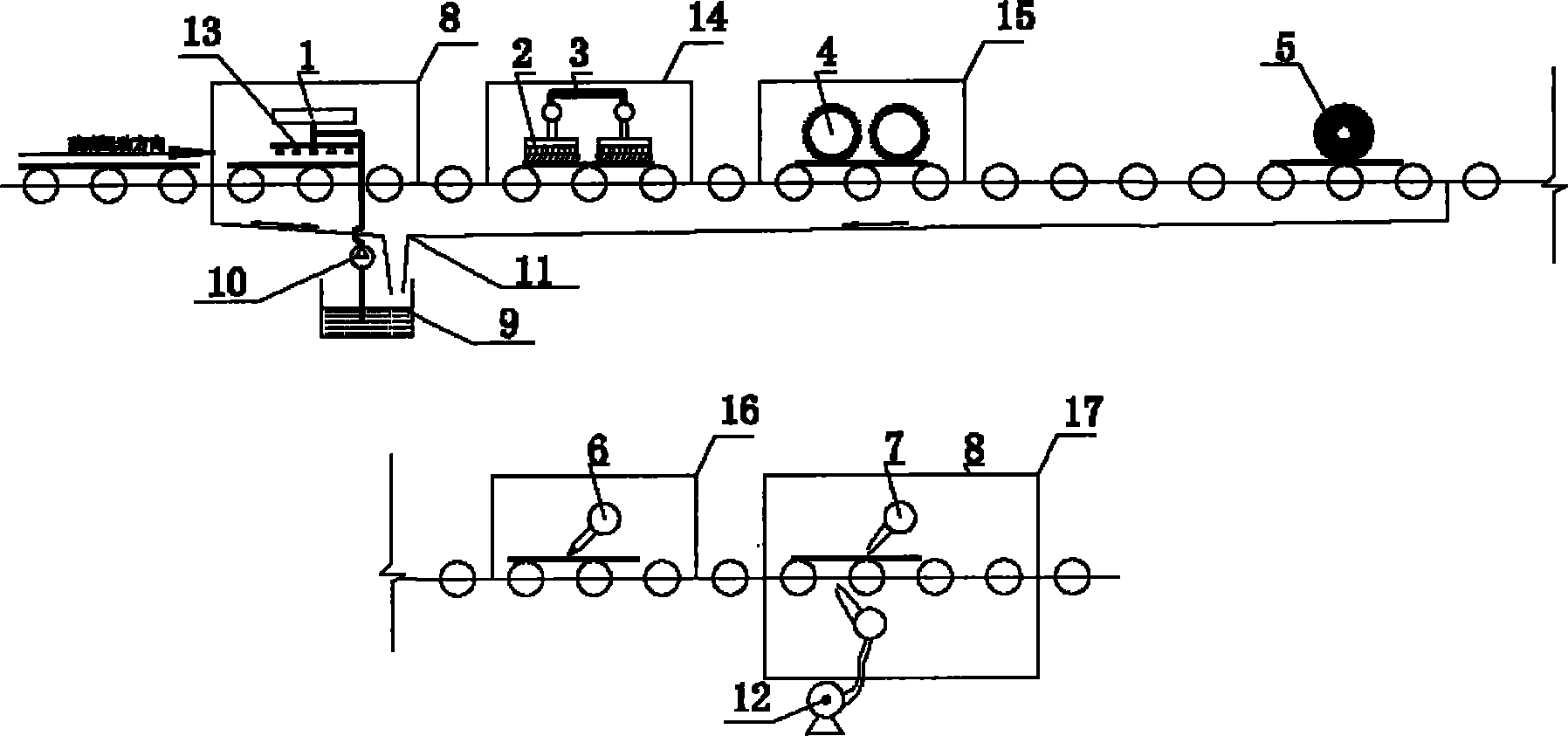

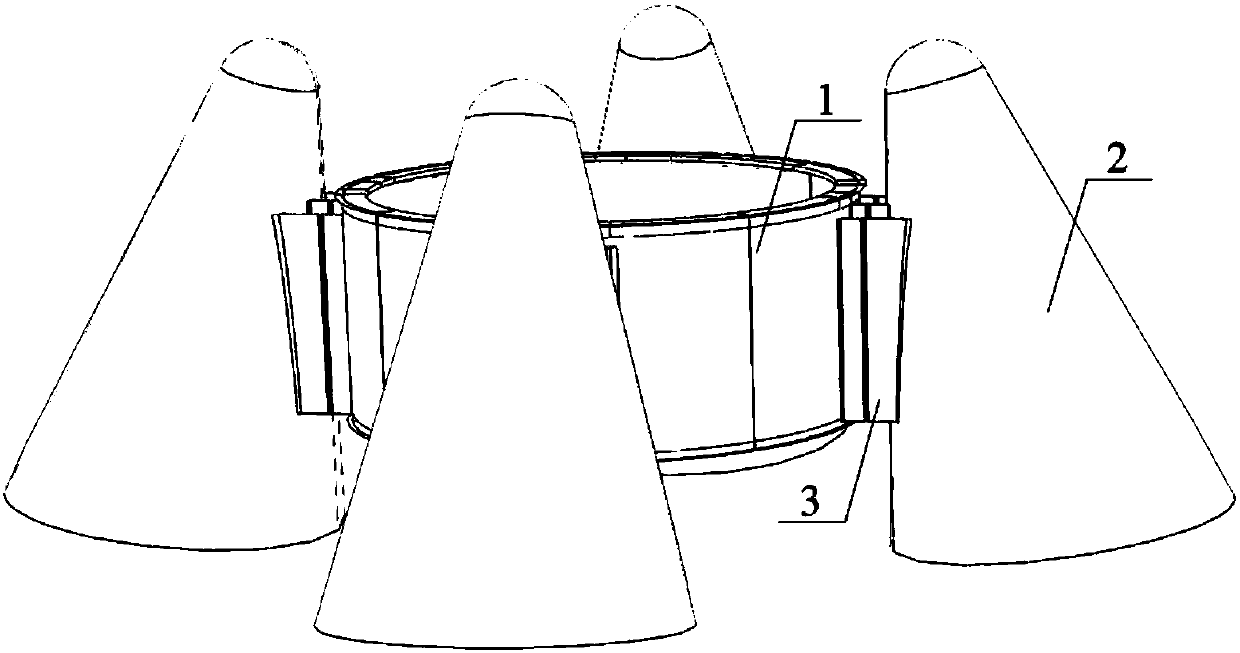

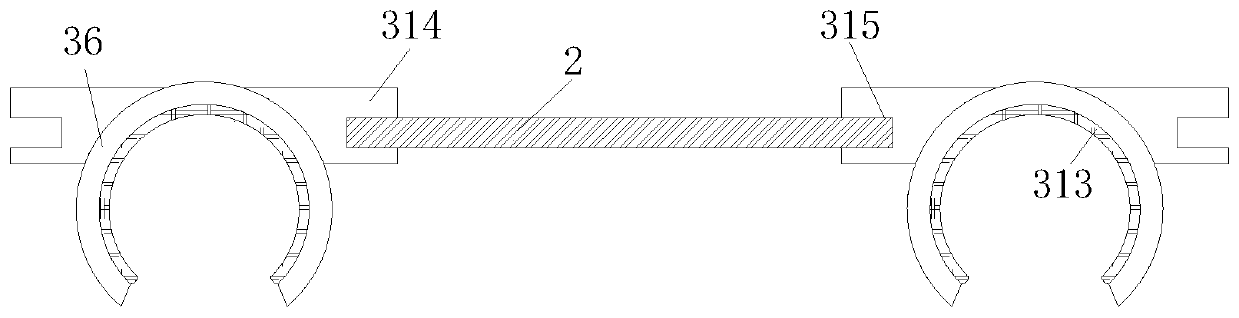

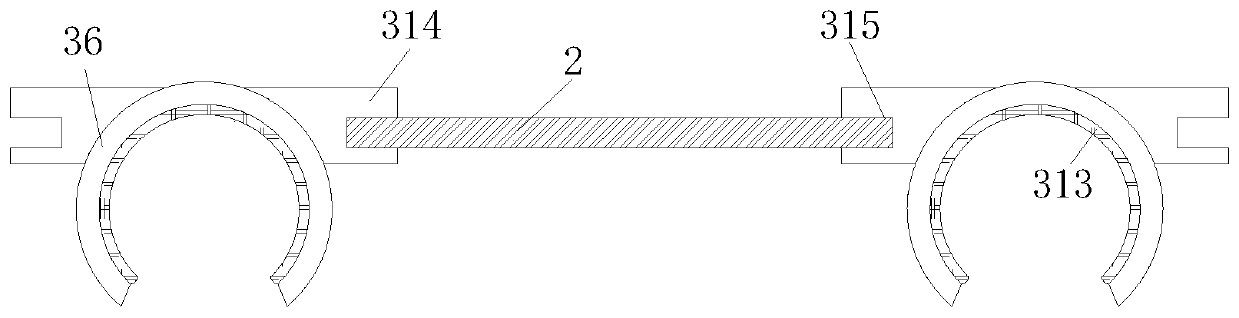

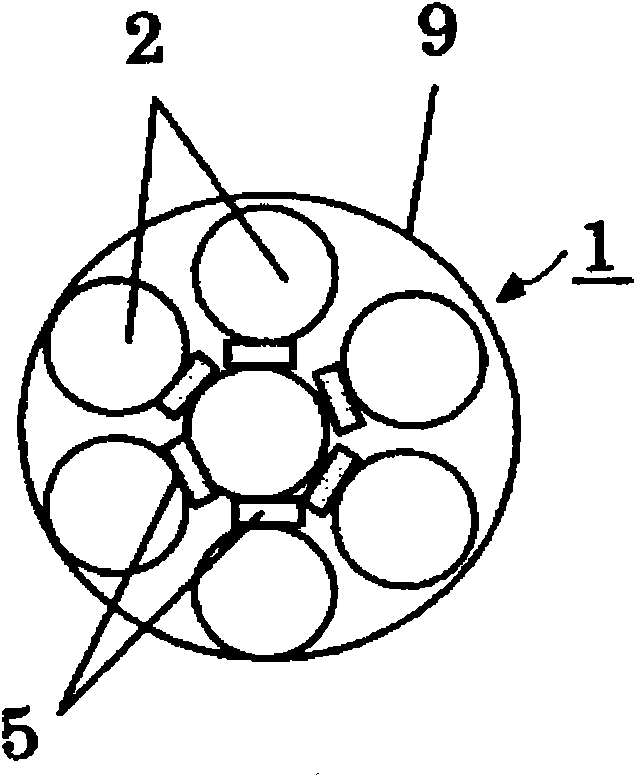

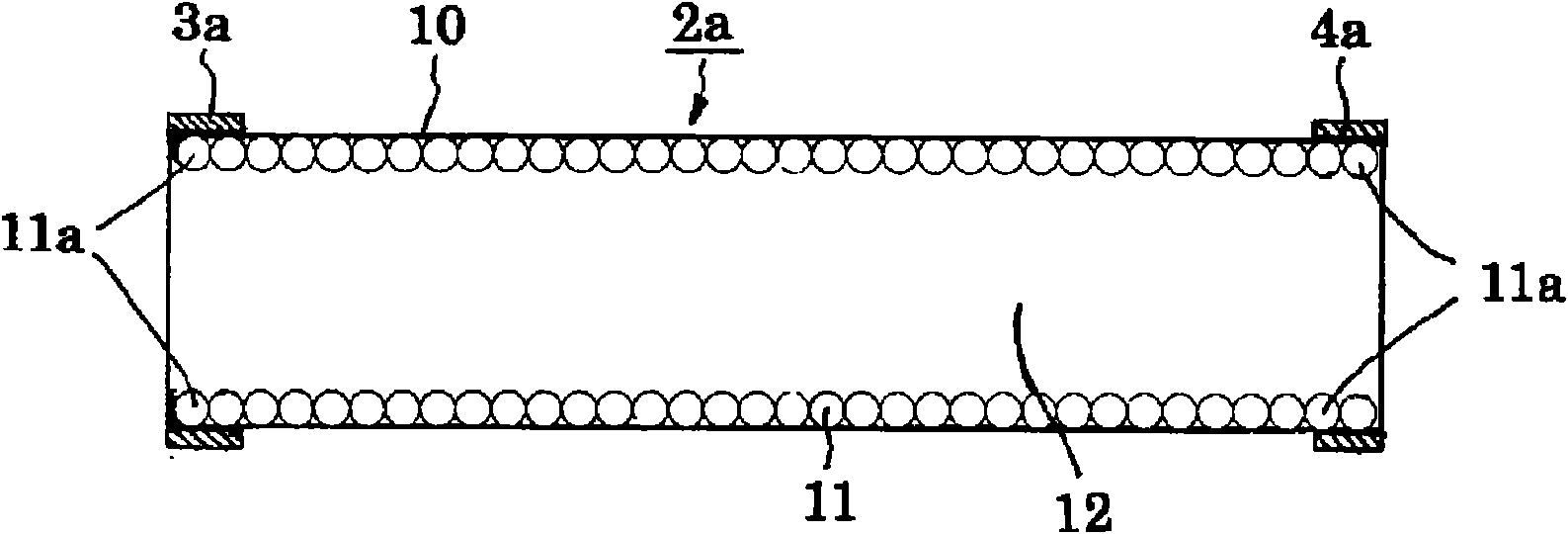

Launch vehicle line type bundling separation device

InactiveCN107585329ALight weightIncrease carrying capacityCosmonautic propulsion system apparatusCosmonautic component separationCarrying capacityAerospace

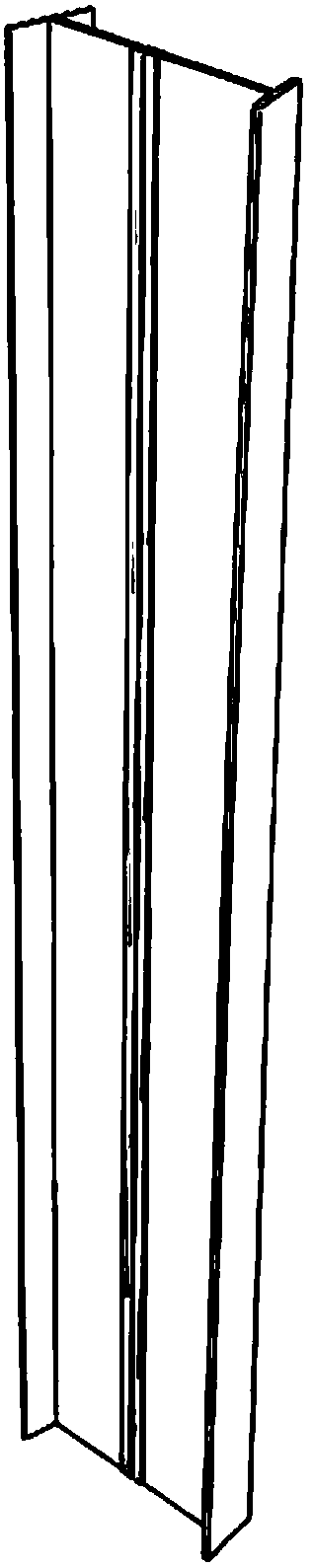

A launch vehicle line type bundling separation device belongs to the field of aerospace structure design. The launch vehicle line type bundling separation device is of a plate structure arranged in the axis direction of a vehicle by taking a separation plate type expansion pipe as a separation system, and the entirety of the bundling separation device is similar to an I-shaped section; the bundling separation device comprises four groups of bundling separation structures, inter-tank sections connected to central stages of the vehicle, and oblique nose cones of boosters. Each group of the bundling separation structures are composed of four I-shaped square plates, and each I-shaped square plate comprises two connecting plates, two separating plates, a metal flat pipe, fillers and a detonating fuse; the metal flat pipe is located between the two connecting plates, and the fillers are placed in the metal flat pipe; the detonating fuse is arranged in the fillers, and used for providing energy during separation; and the two separation plates are used for connecting the ends of web plates on both sides of the two connecting plates. The bundling separation device provided by the inventionhas the advantages of uniform force transmission, weight reduction, improvement of carrying capacity of the vehicle, high bearing capacity and separation reliability, no pollution and small impact during separation.

Owner:DALIAN UNIV OF TECH

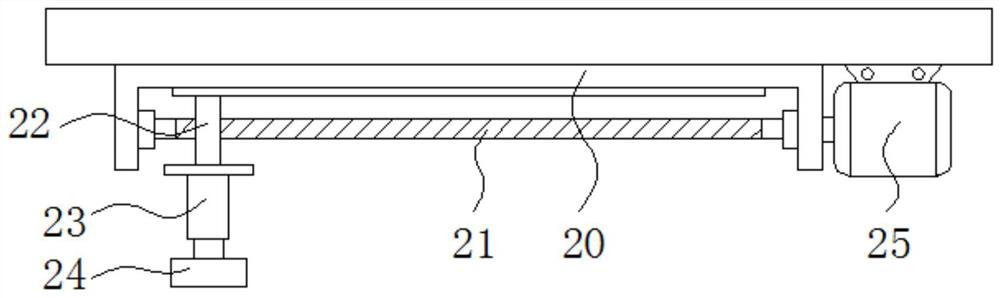

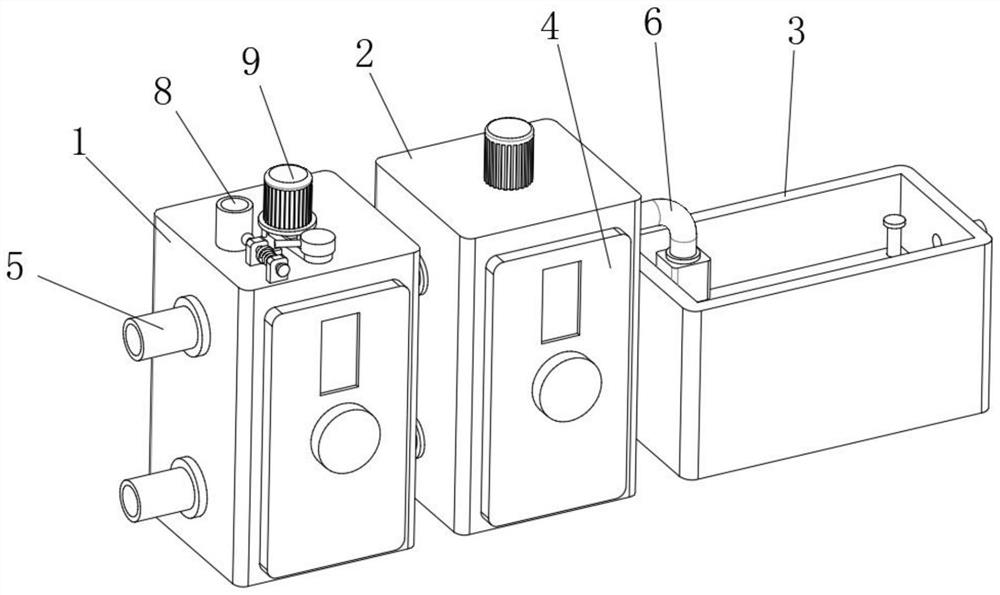

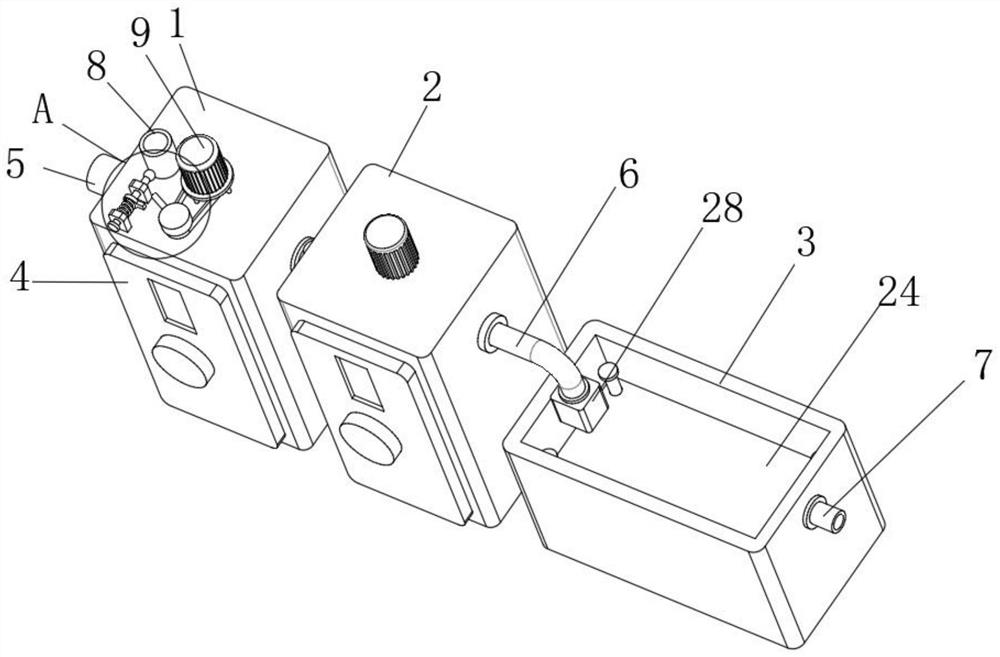

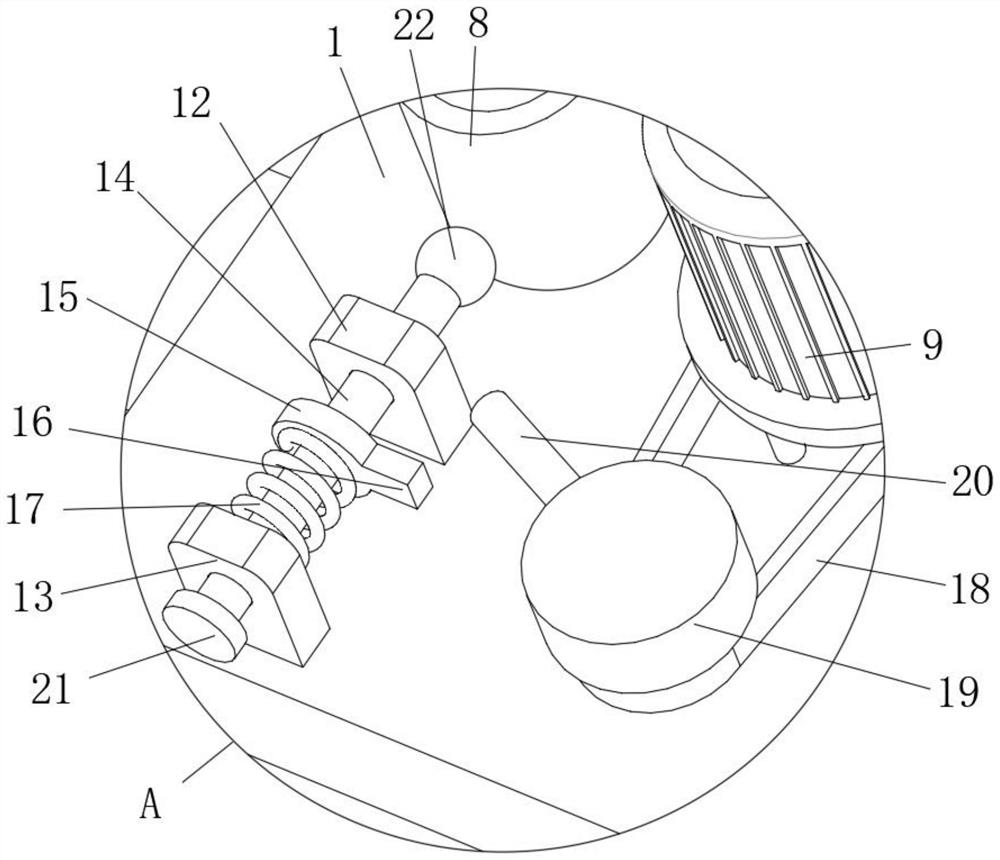

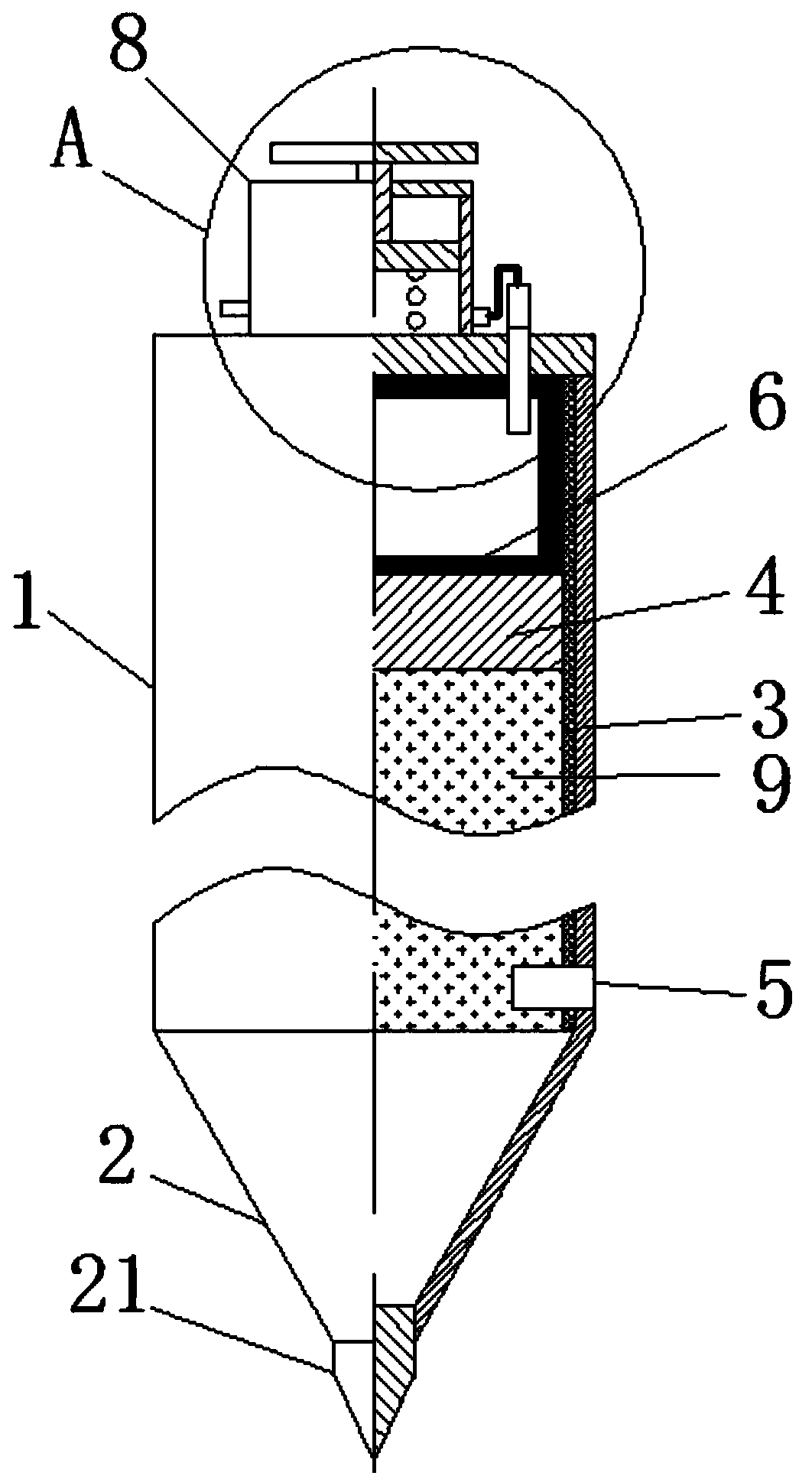

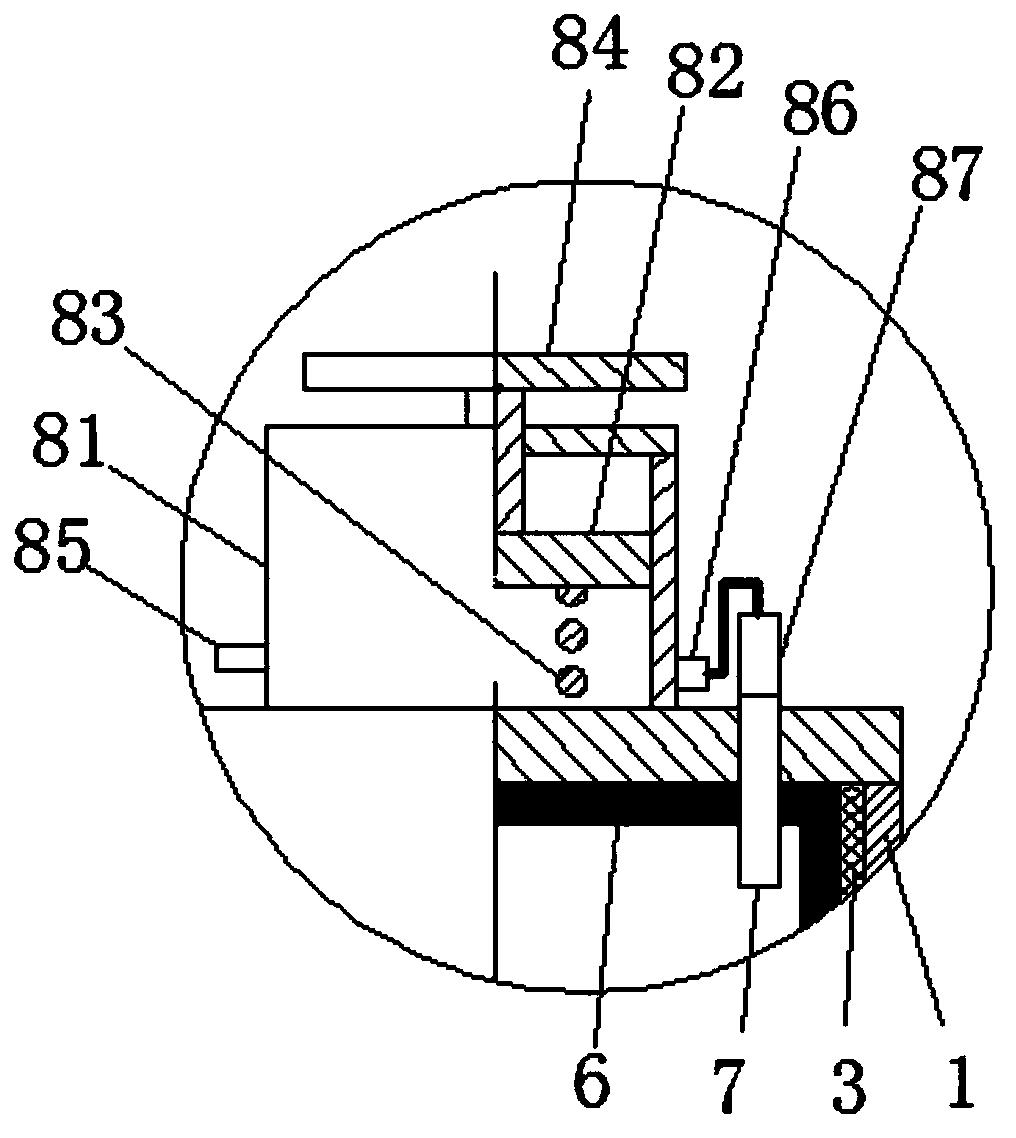

Aluminum scrap recycling device

ActiveCN105522434AReduce energy consumptionIncrease productivityMagnetic separationMaintainance and safety accessoriesMagnetic separatorEngineering

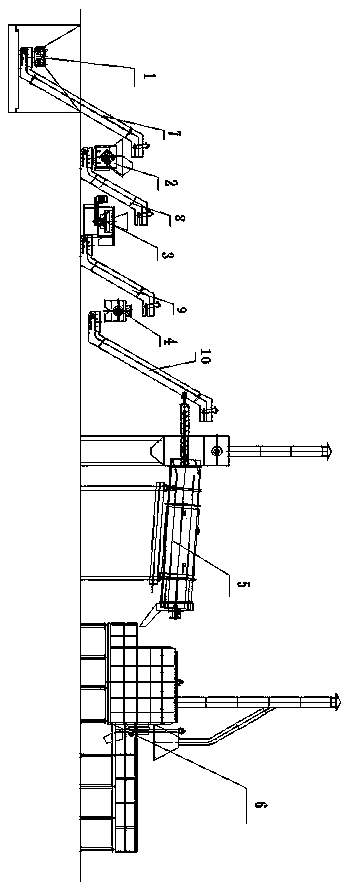

The invention relates to an aluminum scrap recycling device which comprises a duplex packing auger, a crusher, a dehydrator, a magnetic separator, a dryer and a melting tank, wherein a first spreading plate lifter is arranged between the duplex packing auger and the crusher; a second spreading plate lifter is arranged between the crusher and the dehydrator; a third spreading plate lifter is arranged between the dehydrator and the magnetic separator; and a fourth spreading plate lifter is arranged between the magnetic separator and the dryer. The aluminum scrap recycling device is used for recycling aluminum scraps, is low in energy consumption, is high in production efficiency, is safe and reliable, and saves cost.

Owner:ZHENJIANG YUJIU INTELLIGENT EQUIP LTD BY SHARE LTD

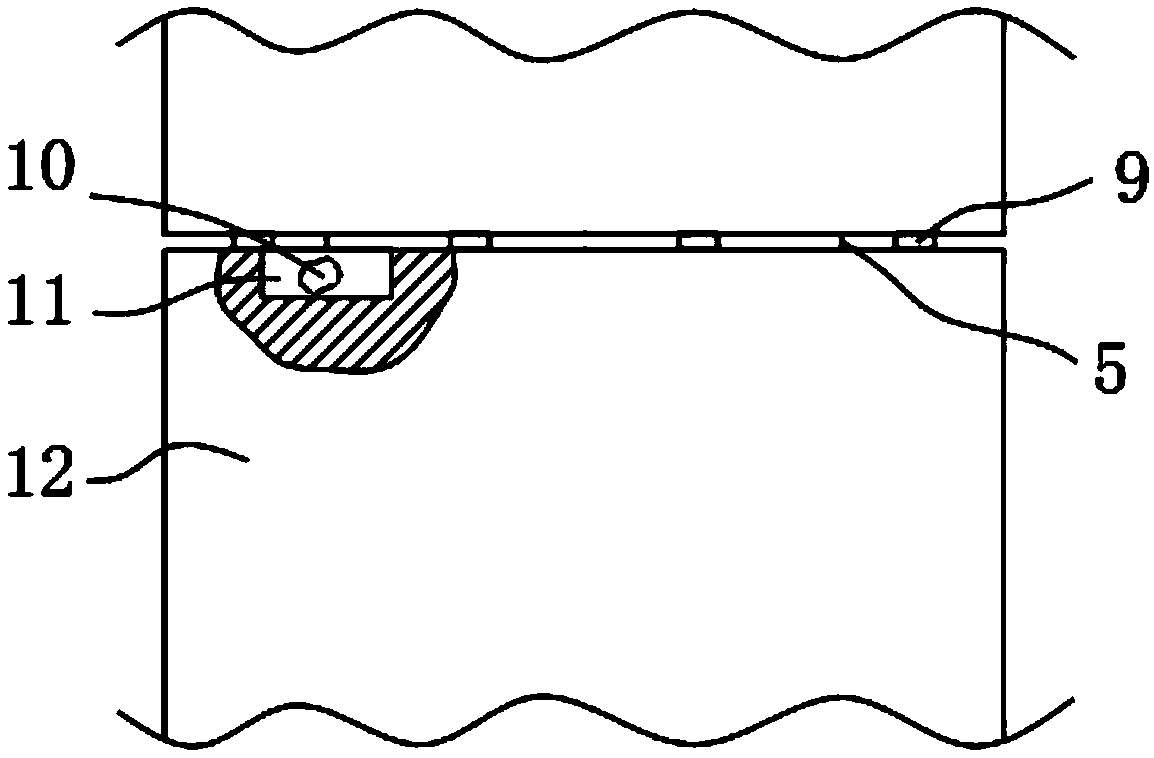

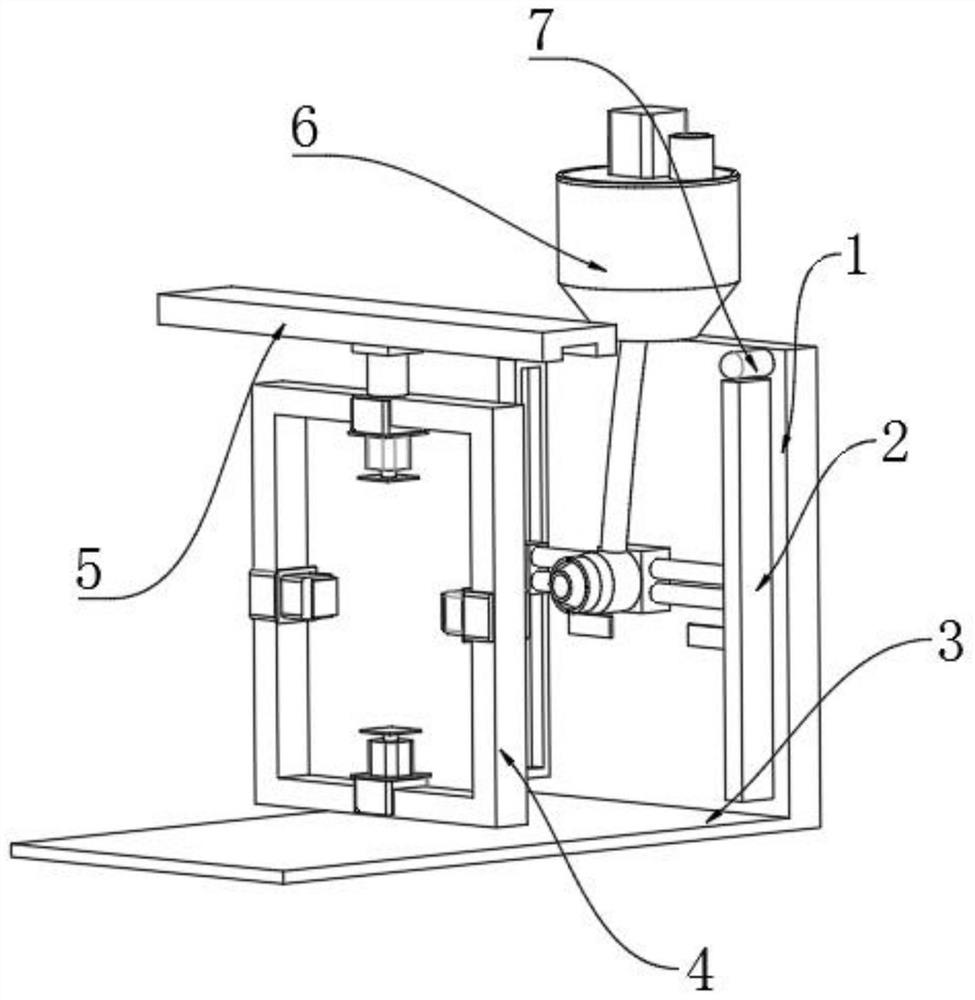

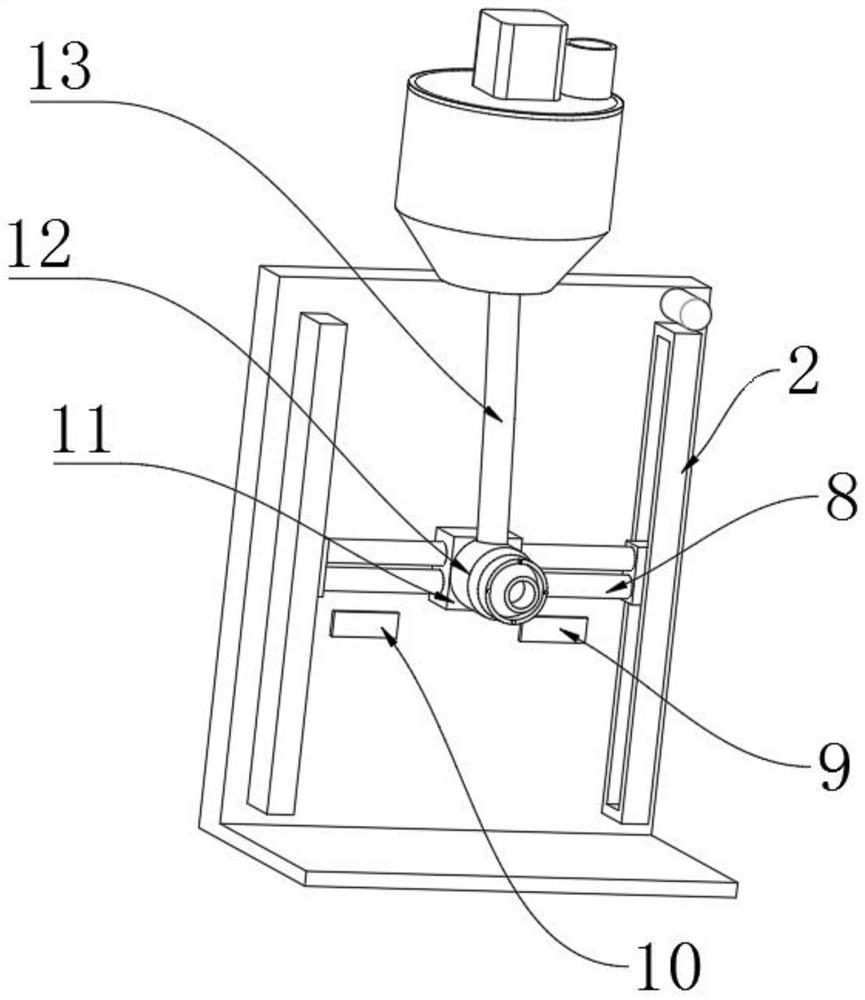

Indenting machine

InactiveCN109514917AQuality assuranceFast absorptionPaper-makingBox making operationsWater vaporMachining

The invention relates to the technical field of paper product machining equipment, in particular to an indenting machine. The indenting machine comprises a machine frame and an upper indenting cutterused for indenting, and further comprises a first releasing plate and a second releasing plate which are connected with the machine frame; an indenting groove is formed between the first releasing plate and the second releasing plate and located below the upper indenting cutter; an elastic hose is arranged in the indenting groove and provided with a plurality of vapor outlets, and water vapor is injected into the elastic hose; the first releasing plate and the second releasing plate can be folded and are hinged to a slide table; and a lower indenting cutter is arranged in the indenting groove,slidably connected with the slide table and connected to a driving device. According to the indenting machine, a paperboard is wetted through the water vapor, the lower indenting cutter extrudes theindented back surface preliminarily, indentations are generated on the indented back surface so that tension can be reduced, indenting is conducted in the releasing plate folding mode, the problem that in the prior art, water sprayed during paperboard indenting is prone to splashing and flowing is solved, cracking of the back surface of the paperboard is prevented, and the indenting quality is improved.

Owner:重庆朝旭印务有限公司

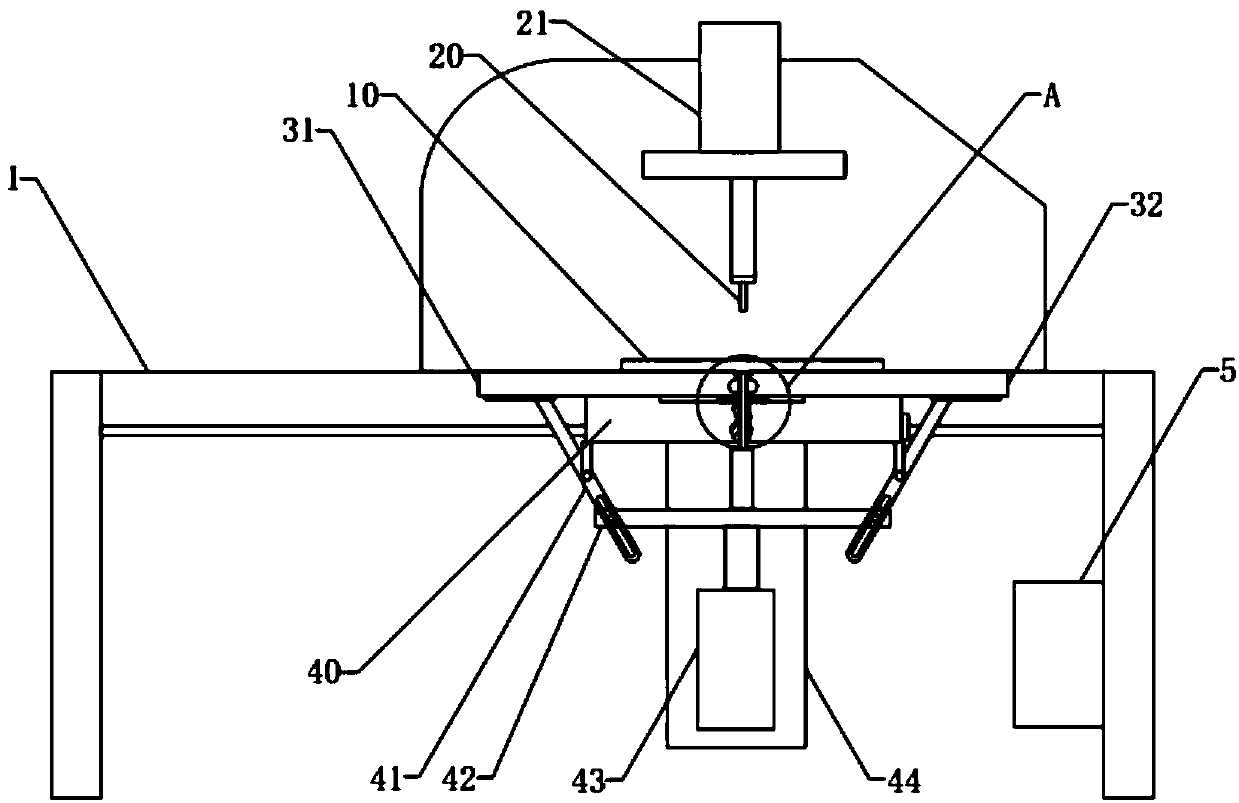

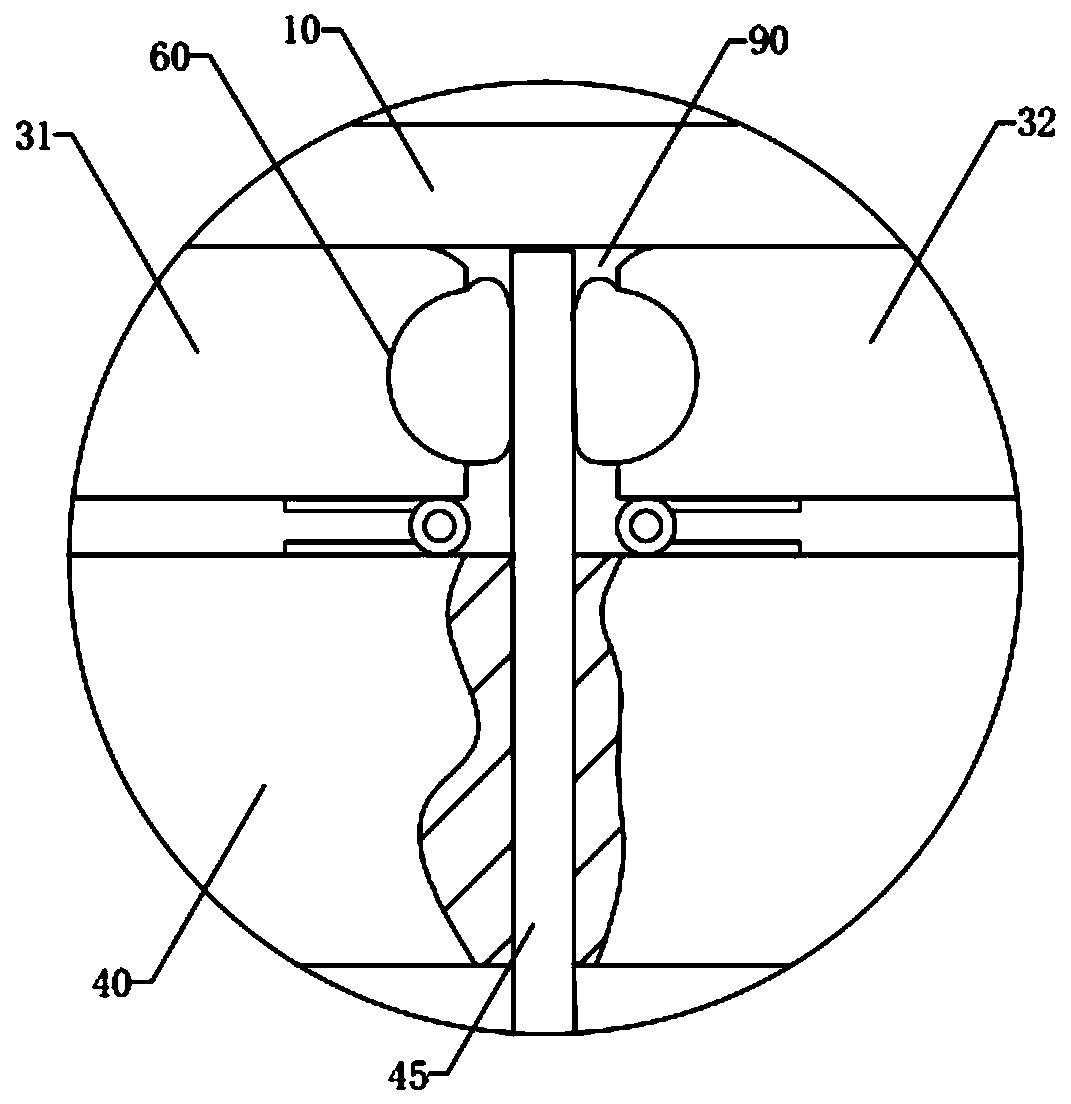

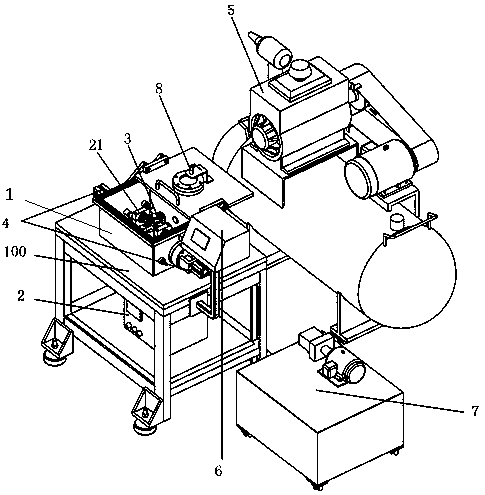

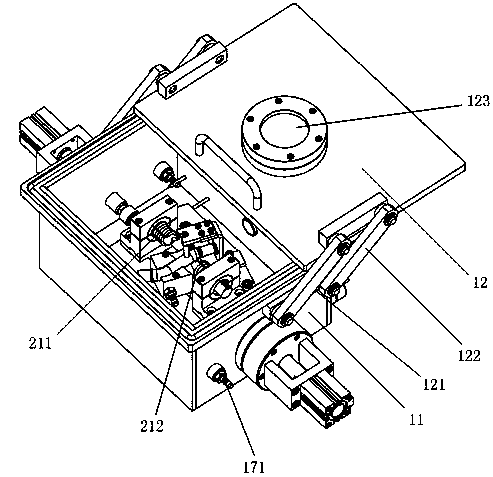

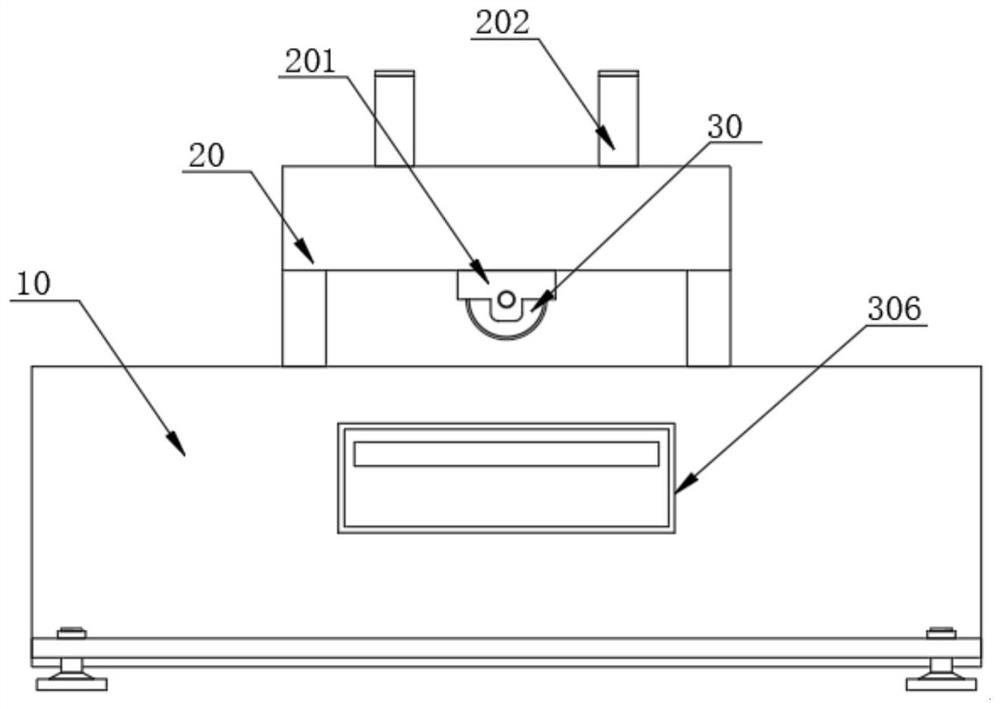

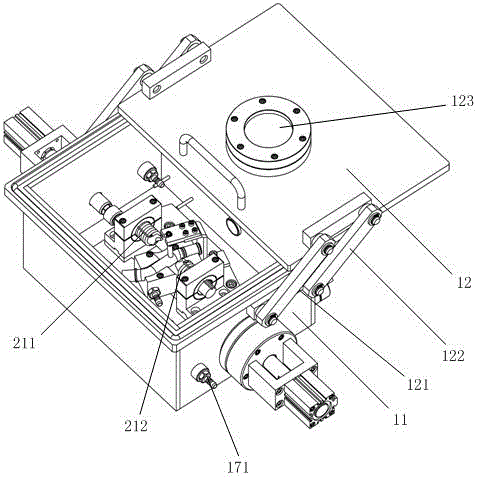

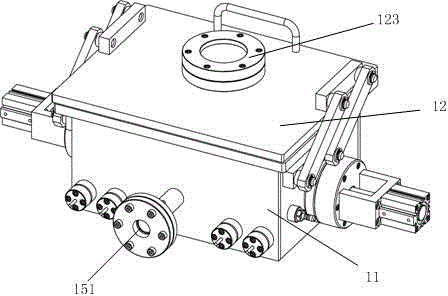

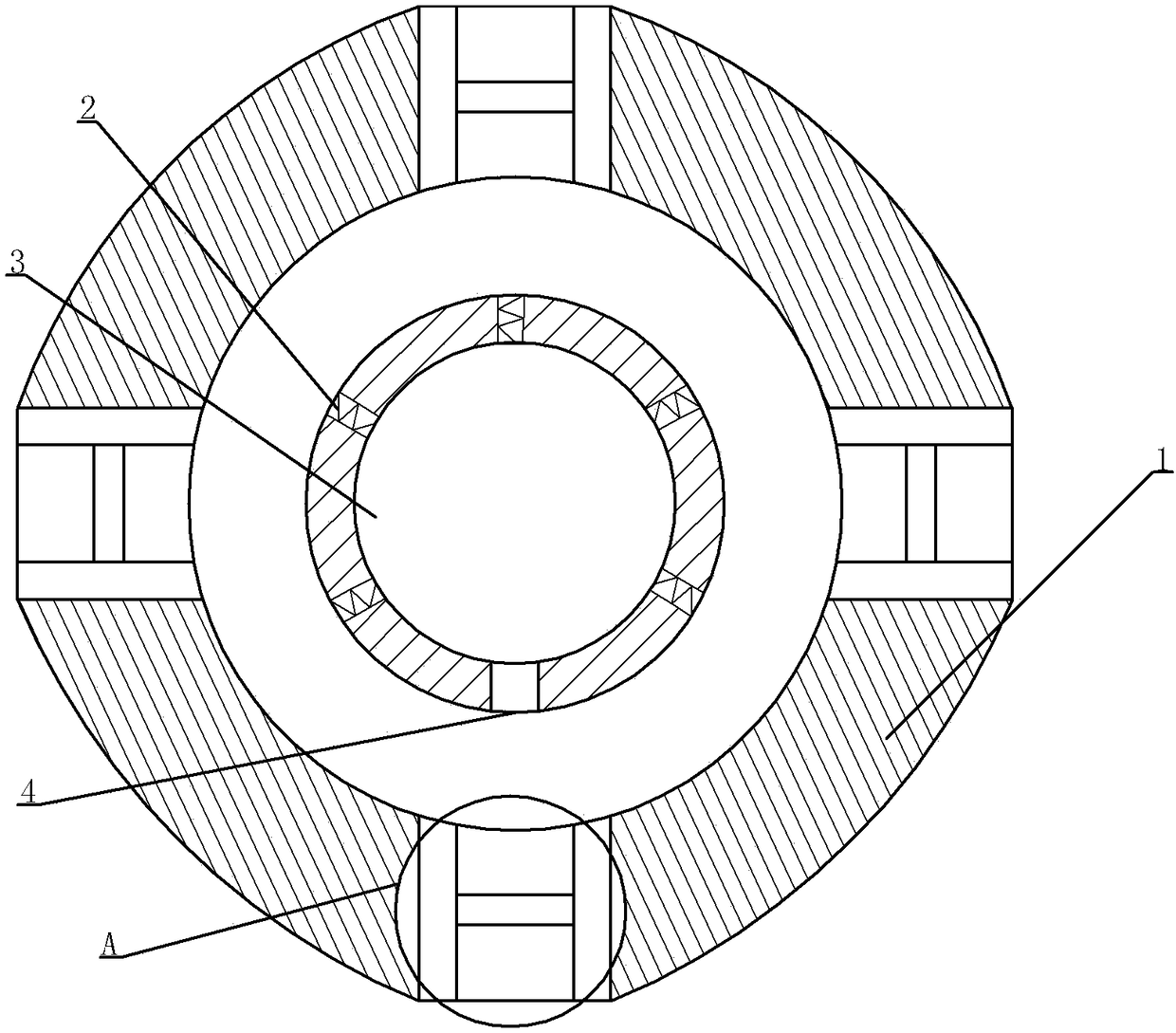

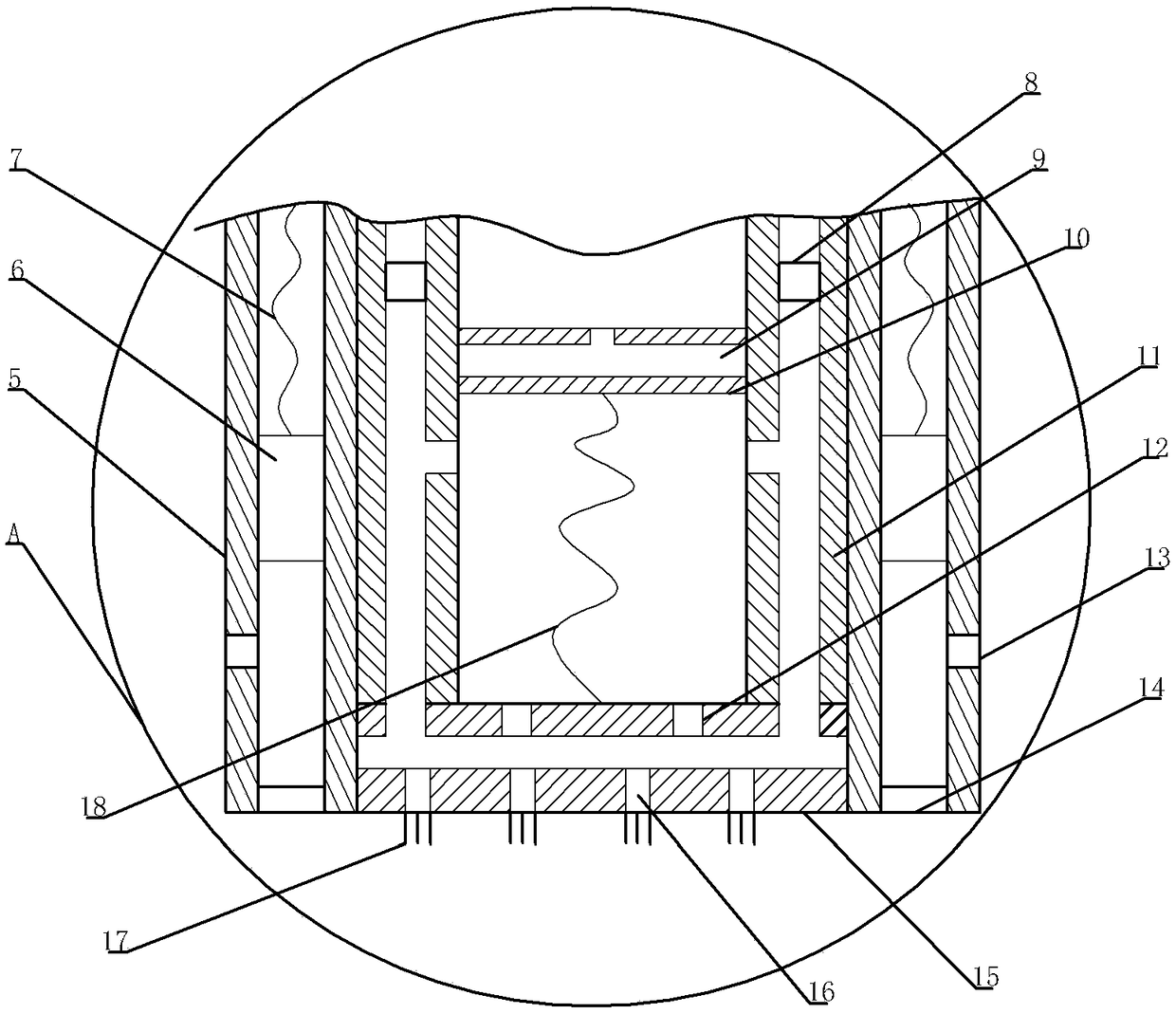

High-frequency brazing machine

ActiveCN104174960AImprove qualityReduce precisionHeating appliancesSoldering auxillary devicesEddy currentEngineering

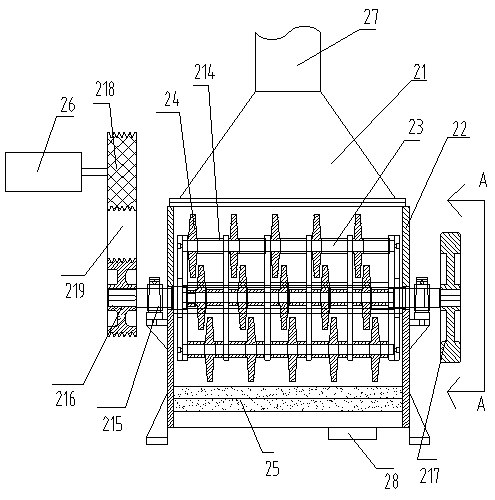

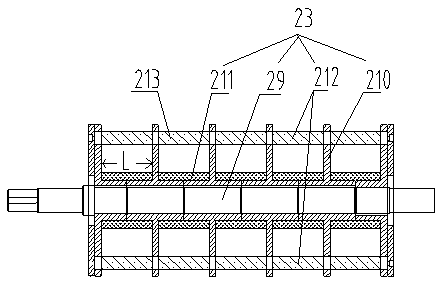

The invention discloses a high-frequency brazing machine which comprises a worktable, a vacuum system component and a cooling component. A welding work box, a high-frequency generator, a programmed control device and a temperature detection component are arranged on the worktable, a work fixture and a high-frequency magnetic bar coil are arranged in the welding work box, the work fixture fixes a workpiece to be welded, a pneumatic drive workpiece is arranged at one end of the welding work box and connected with the work fixture and drives the work fixture to run, and the programmed control device is connected with the vacuum system component, the pneumatic drive workpiece, the high-frequency generator, the cooling component and the temperature detection component. By the mode, the high-frequency brazing machine realizes brazing by the aid of eddy current, safety can be guaranteed, and the high-frequency brazing machine is low in risk and cost, high in efficiency and fine in welding performance.

Owner:CHANGSHU JUNCHI SCI & TECH

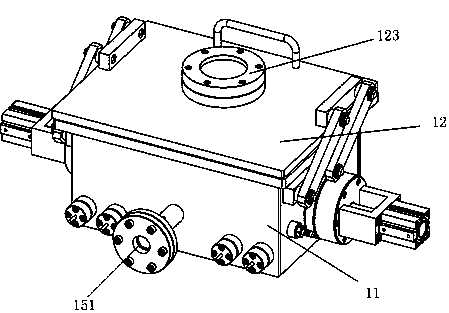

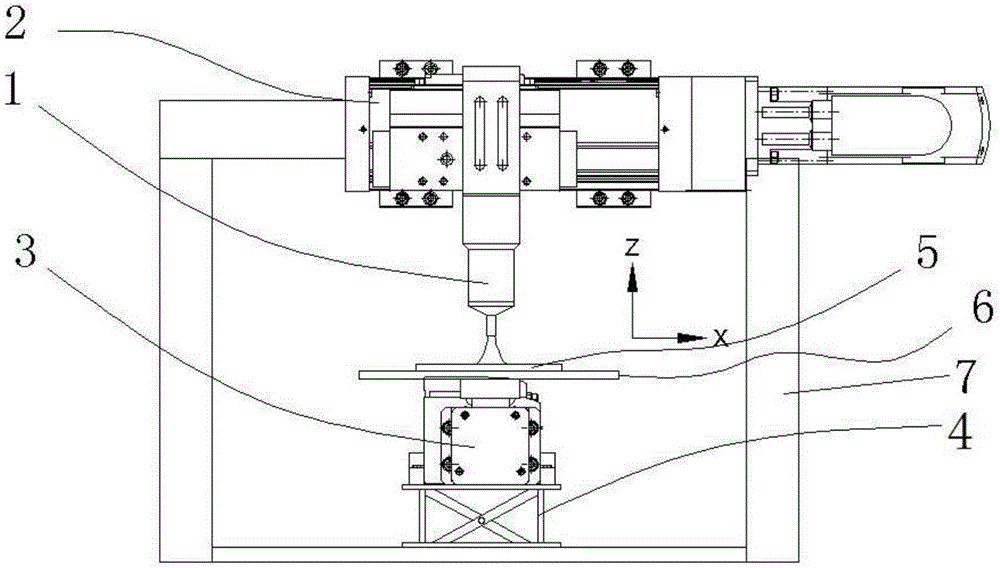

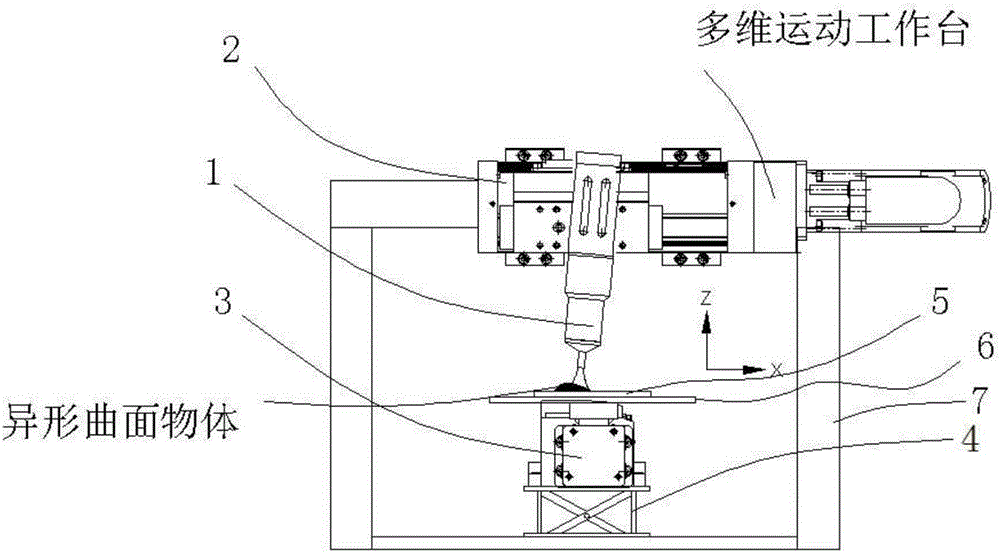

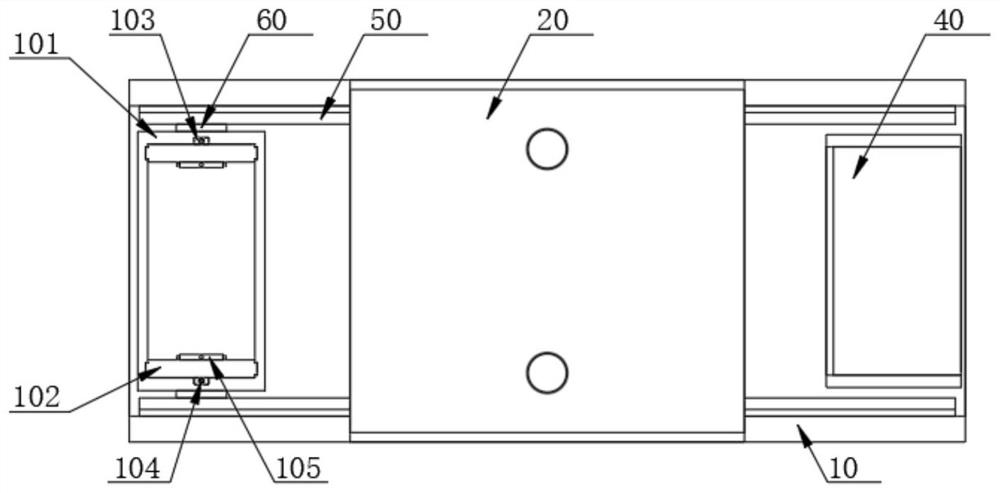

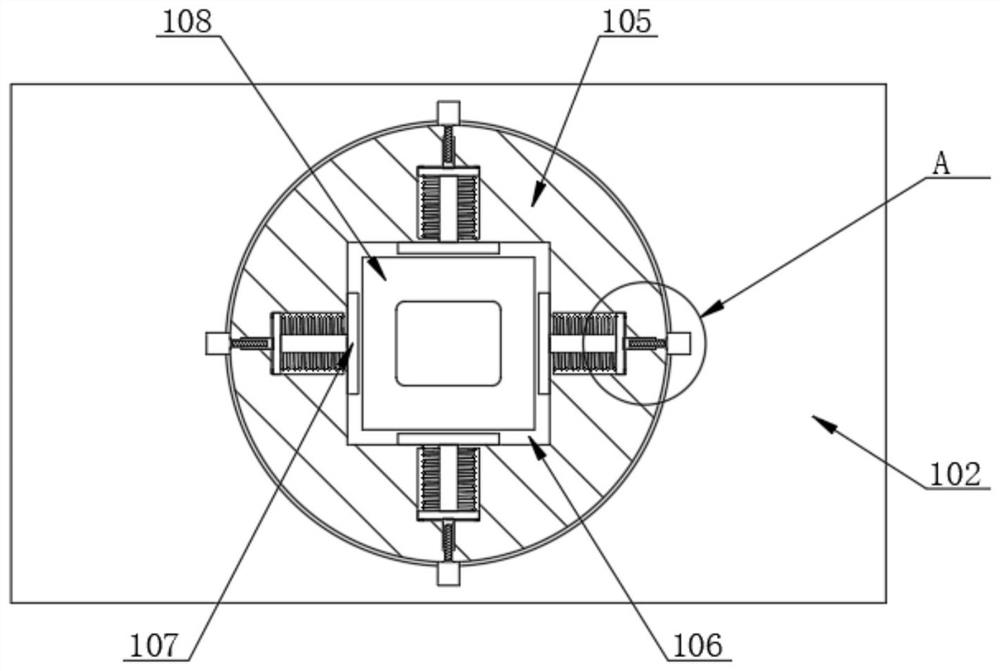

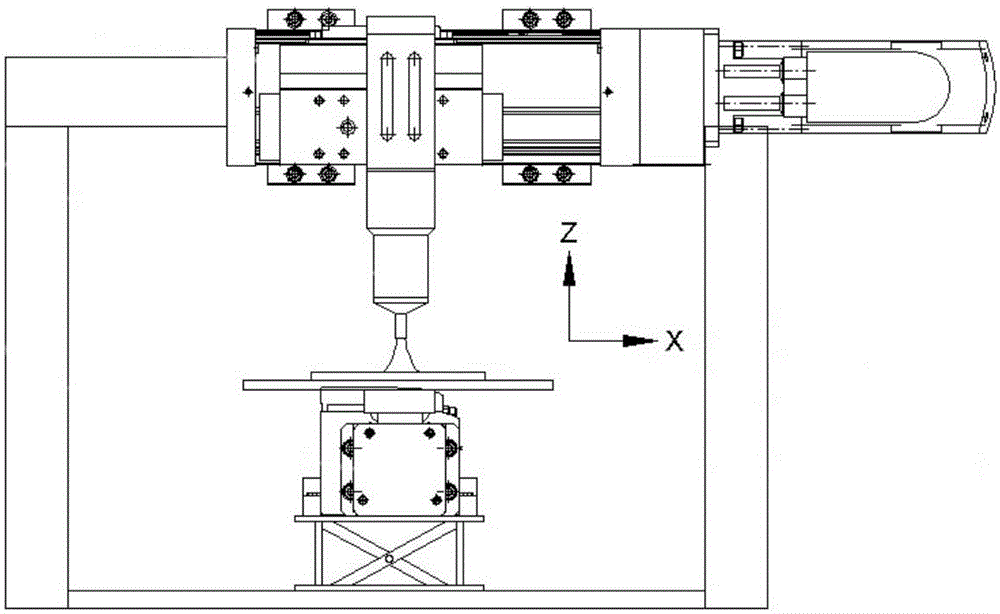

Convenient type atmosphere plasma sterilization equipment

InactiveCN106492247AGuaranteed mechanical strengthGuaranteed mechanical toughnessLavatory sanitoryDisinfectionPlasma jetPlasma sterilization

The invention provides convenient type atmosphere plasma sterilization equipment which comprises an open type cuboid equipment body, wherein a plasma sterilizer is arranged on the equipment body; a storage table for storing to-be-sterilized articles and a mobile working platform for adjusting the relative positions of the storage platform and the plasma sterilizer are further arranged inside the equipment body; the mobile working platform consists of an X-direction mobile working platform, a Y-direction mobile working platform and a Z-direction mobile working platform; the storage platform is arranged on the Y-direction mobile working platform; and the plasma sterilizer consists of a plasma generation power supply, a plasma jetting nose and a mounting piece. The convenient type atmosphere plasma sterilization equipment can conduct sterilization and disinfection in an atmosphere state, does not need low-pressure environment and is not limited by shapes and sizes.

Owner:合肥优亿科机电科技有限公司

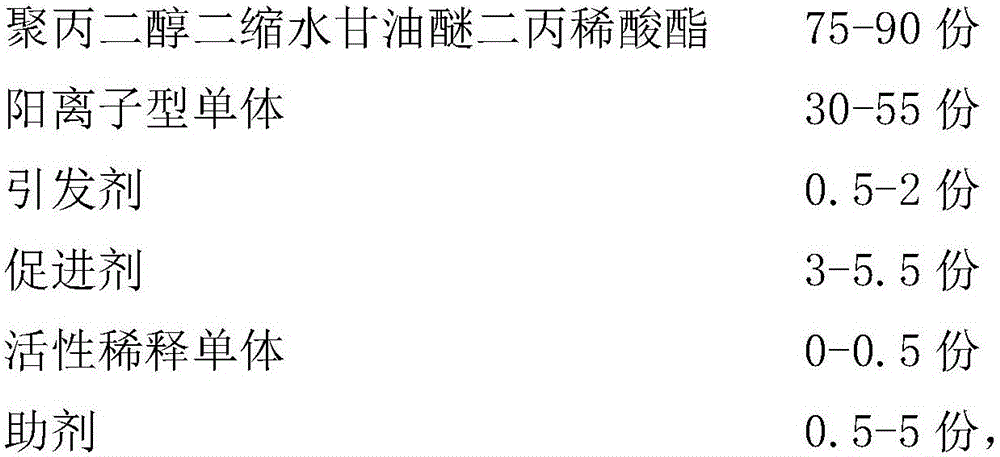

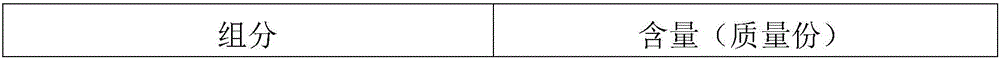

Jet type 3D-printing light curing material

InactiveCN106221177ALow viscositySmall volume shrinkageAdditive manufacturing apparatusPolypropylene glycolWorking temperature

The invention discloses a jet type 3D-printing light curing material. The formula of the material comprises 75 to 90 parts of polypropyleneglycol diglycidyl ether diacrylate, 30 to 55 parts of cationic monomers, 0.5 to 2 parts of initiators, 3 to 5.5 parts of accelerators, 0 to 0.5 part of an active diluent monomer and 0.5 to 5 parts of additives, in parts by weight, wherein the density of the polypropyleneglycol diglycidyl ether diacrylate is 1.16g / cm<2> at the temperature of 25 DEG C, and the viscosity of the polypropyleneglycol diglycidyl ether diacrylate is 1810mPs.s; during the 3D printing process of the polypropyleneglycol diglycidyl ether diacrylate, the nozzle working temperature is 50 to 55 DEG C, and the surface tension is 31.5 to 31.0mN / m; when the material is prepared, the accelerators are used after being added into the cationic monomers to be uniformly mixed, and the mass ratio of the cationic monomers to the accelerators is 10:1. The light curing material disclosed by the invention is relatively high in light curing speed, and the mechanical properties of the light-cured material are relatively good.

Owner:SUZHOU BC TECH

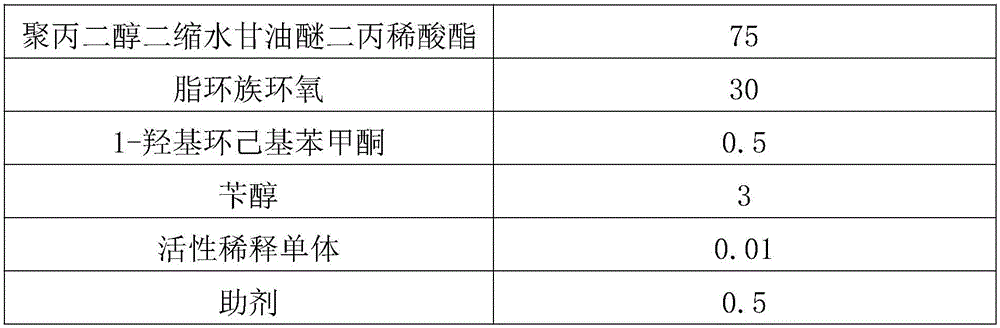

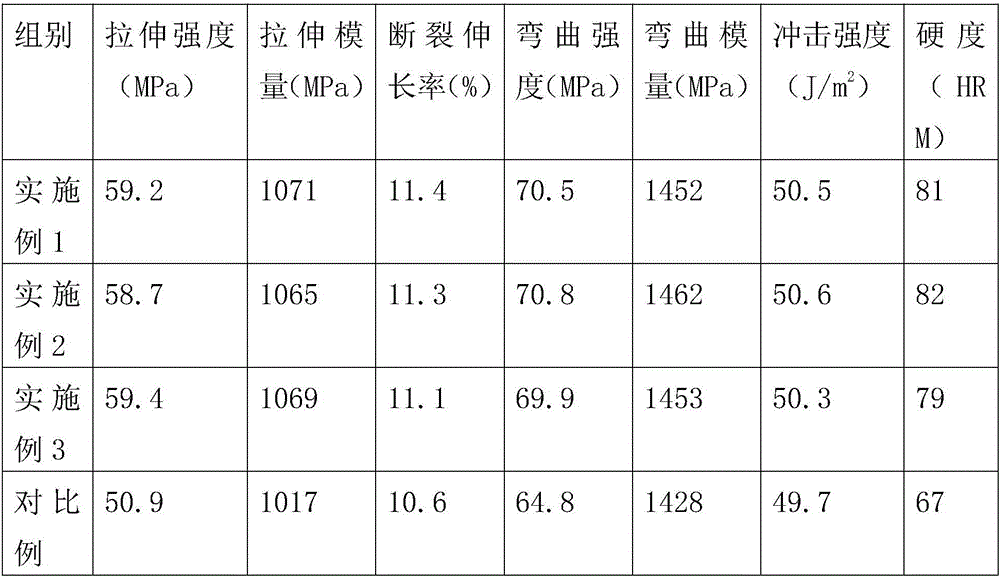

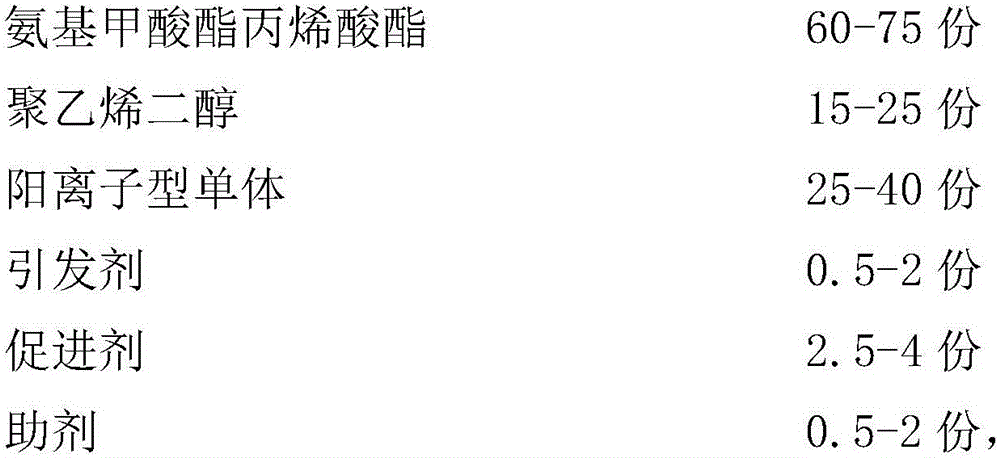

Low-viscosity 3D (three-dimensional) printing photo-curing material

InactiveCN106189199AImprove mechanical propertiesLow viscosityAdditive manufacturing apparatusSprayerWorking temperature

The invention discloses a low-viscosity 3D (three-dimensional) printing photo-curing material. The low-viscosity 3D printing photo-curing material comprises, by weight, 60-75 parts of urethane acrylate, 15-25 parts of polyethylene glycol, 25-40 parts of cationic monomers, 0.5-2 parts of initiators, 2.5-4 parts of accelerators and 0.5-2 parts of auxiliaries. The density of the urethane acrylate at the temperature of 25 DEG C is 1.09 g / cm<3>, the viscosity of the urethane acrylate is 150-175 mPs.s, and surface tension of the urethane acrylate is 39.5-39.1 mN / m under the condition that the working temperatures of sprayers are 50-55 DEG C in 3D printing procedures; the accelerators are added into the cationic monomers when materials are prepared, the low-viscosity 3D printing photo-curing material can be used after the accelerators and the cationic monomers are uniformly mixed with one another, and a mass ratio of the cationic monomers to the accelerators is 10:1. The low-viscosity 3D printing photo-curing material has the advantages that reactive diluents can be omitted, and the low-viscosity 3D printing photo-curing material is high in photo-curing speed; the low-viscosity 3D printing photo-curing material is good in mechanical property after being photo-cured, and the relative cost of the low-viscosity 3D printing photo-curing material can be reduced.

Owner:SUZHOU BC TECH

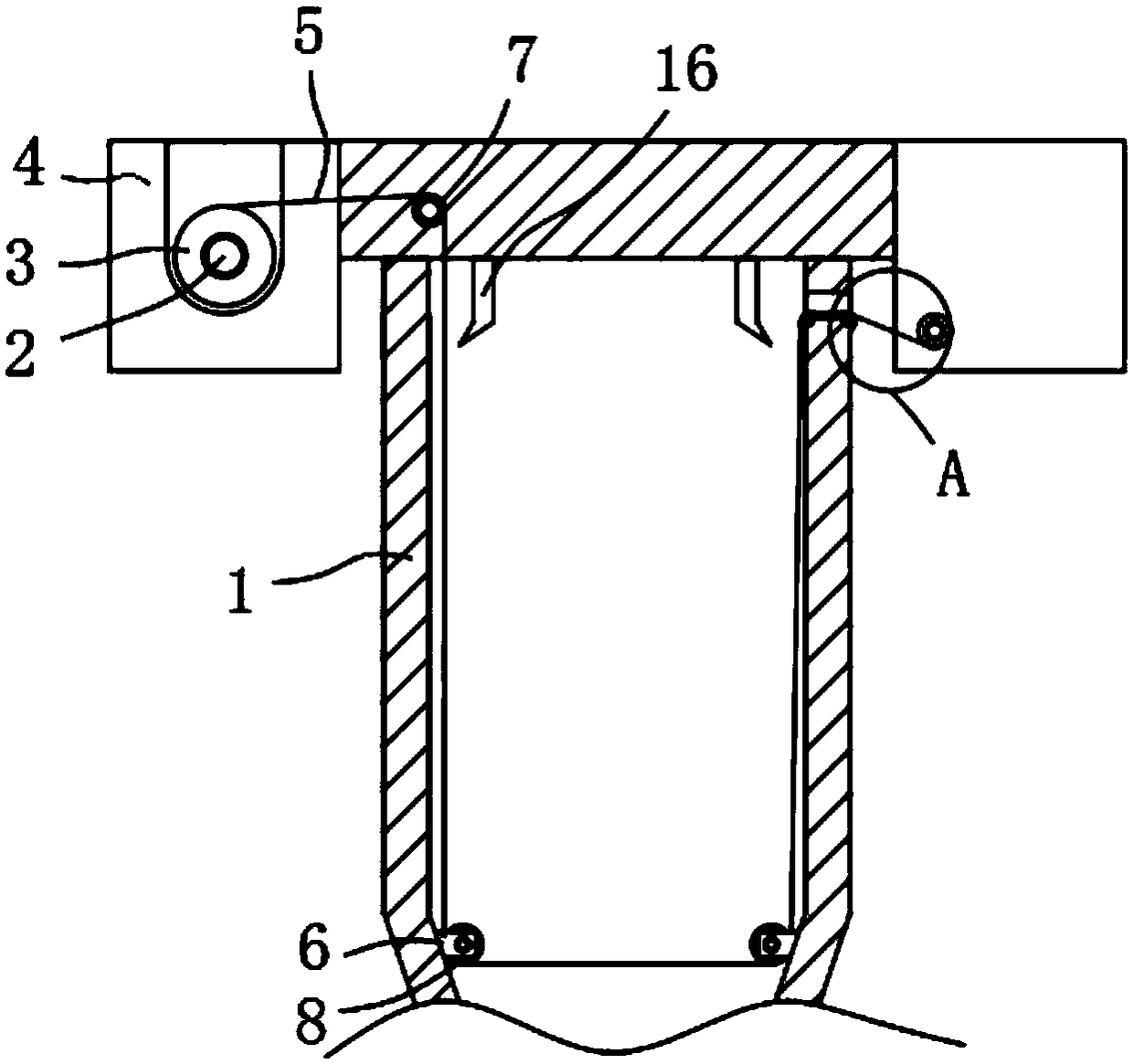

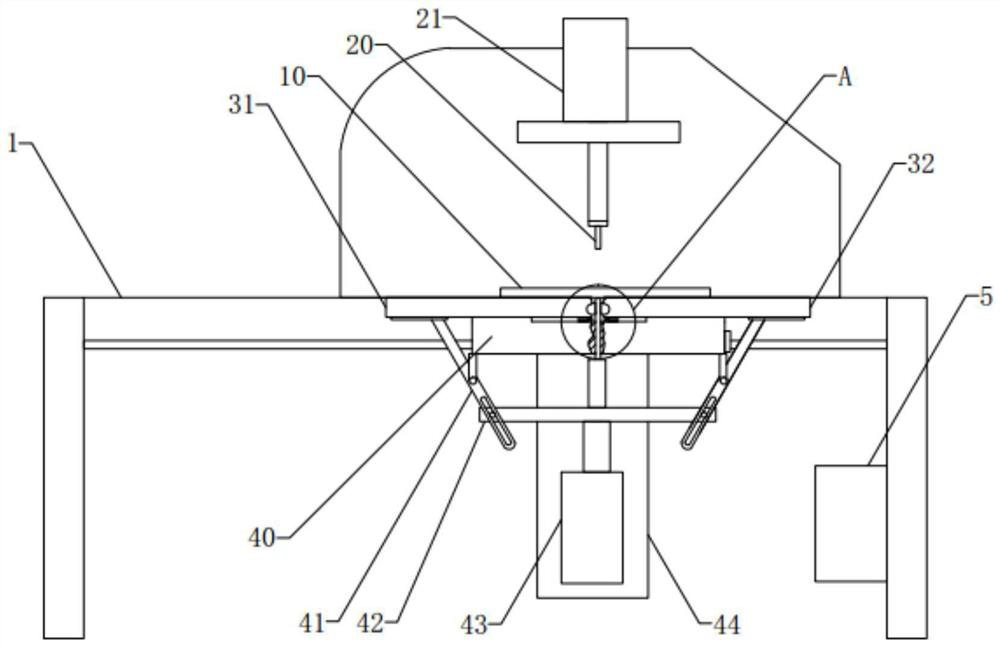

Environment-friendly battery manufacturing mechanical equipment

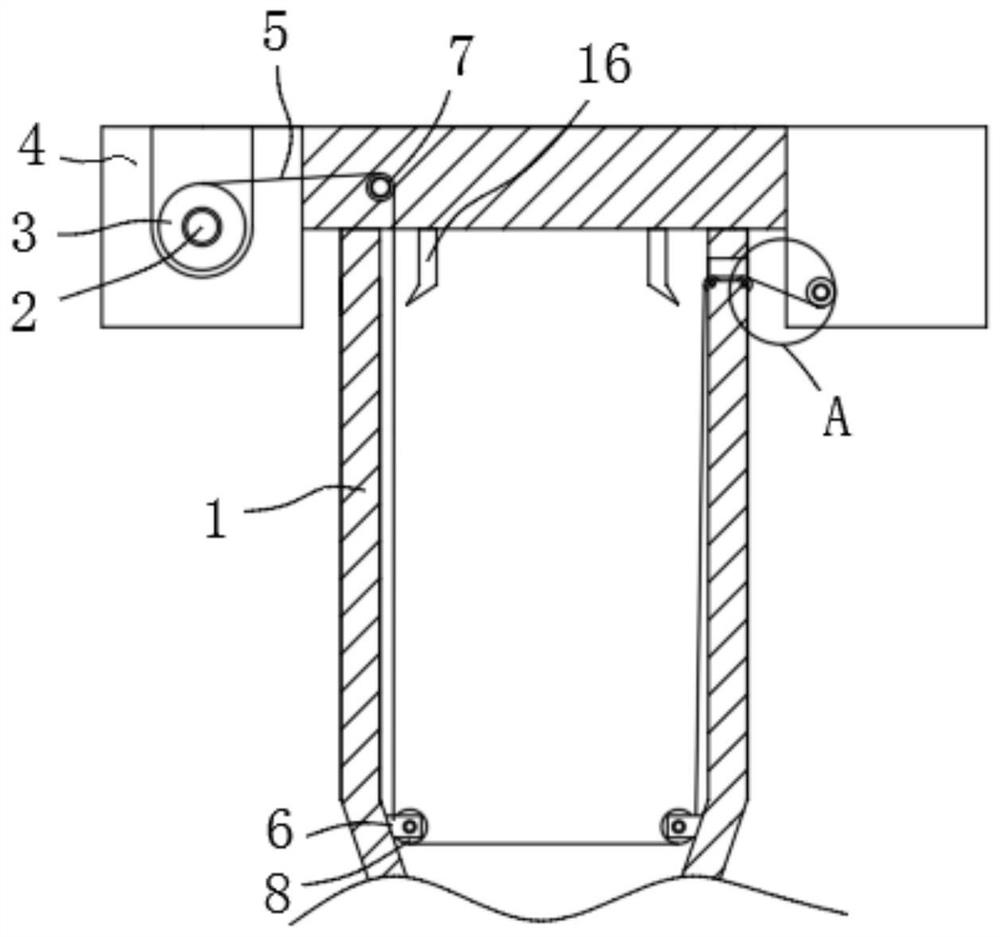

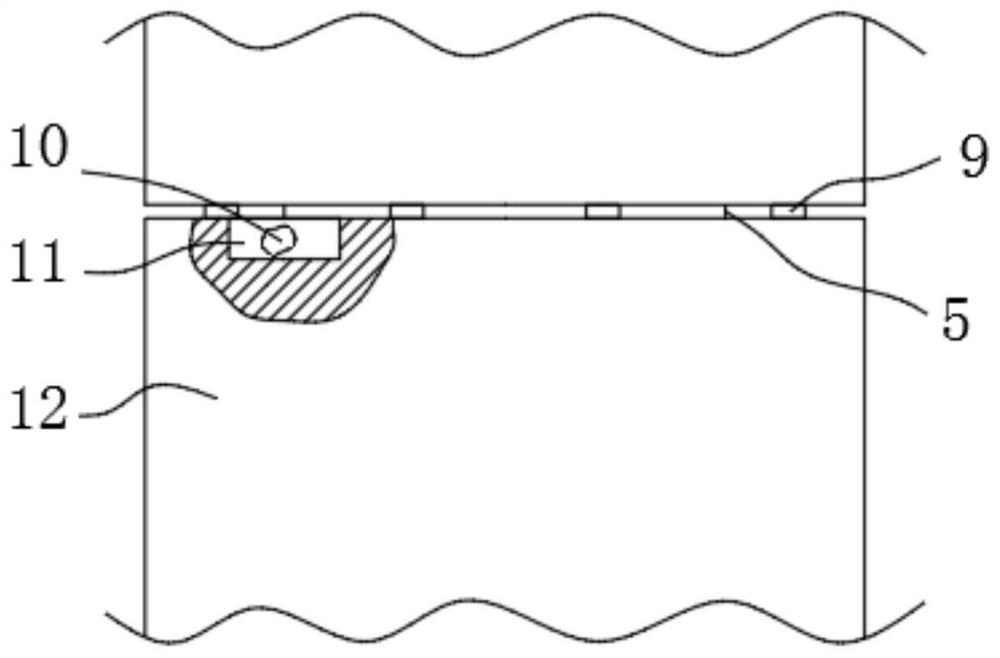

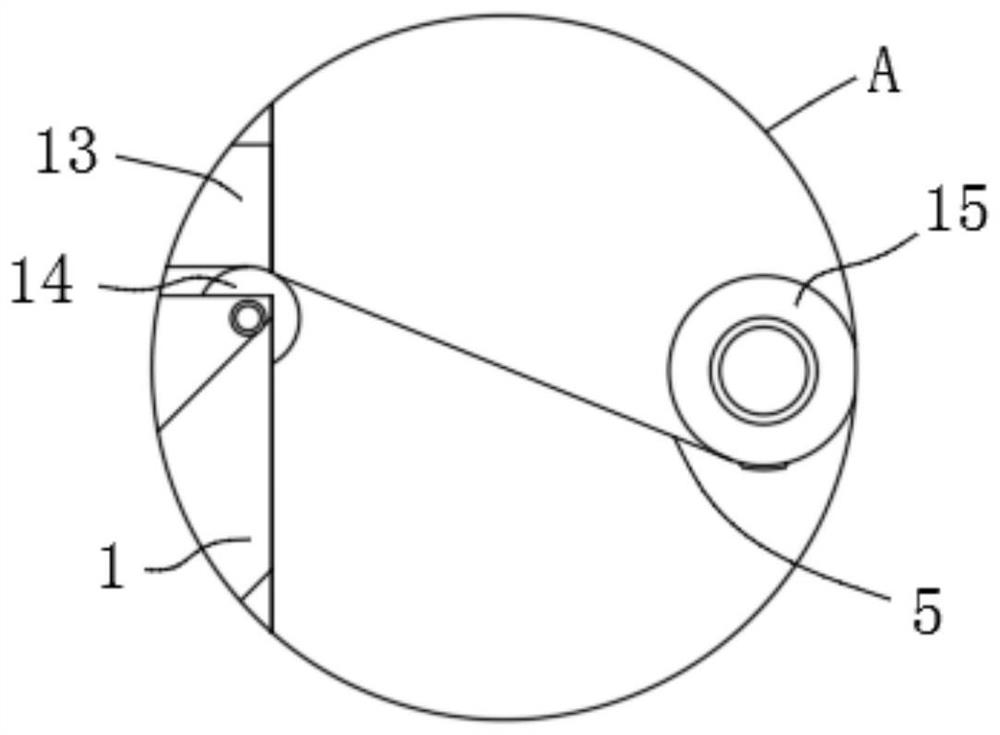

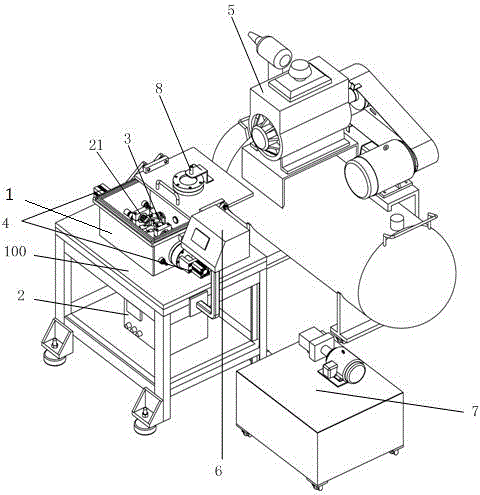

ActiveCN110993540ADrying will not affectNo vibrationFinal product manufactureSemiconductor/solid-state device manufacturingCell fabricationProcess engineering

The invention provides environment-friendly battery manufacturing mechanical equipment, which comprises a spin-drying box for spin-drying a silicon wafer for a solar battery, the battery silicon wafer, an active spin-drying mechanism for controlling the battery silicon wafer to spin-dry moisture in a rotating manner, and an environment-friendly discharging mechanism for guiding wastewater and gasto be discharged in a layered manner, and relates to the field of battery manufacturing. According to the environment-friendly battery manufacturing mechanical equipment, re-planning can be carried out on the basis of a spin-drying technology of a silicon wafer; the spin-drying use area is increased under the condition of the same output; energy saving, meanwhile, the influence of corrosive gas and liquid on equipment can be reduced when the gas and the liquid are discharged; equipment service life is extended, waste is turned into wealth, recycling of energy is promoted, and therefore the problems that in the silicon solar energy spin-drying process of common spin-drying equipment, due to the fact that the gas-liquid flow speed difference is large and the gas-liquid passing space is small, certain hidden danger of corrosion and pipe explosion is likely to exist, and certain environmental protection is likely to be generated due to long-time high-strength production are effectively solved.

Owner:广州爱邦建筑科技有限公司

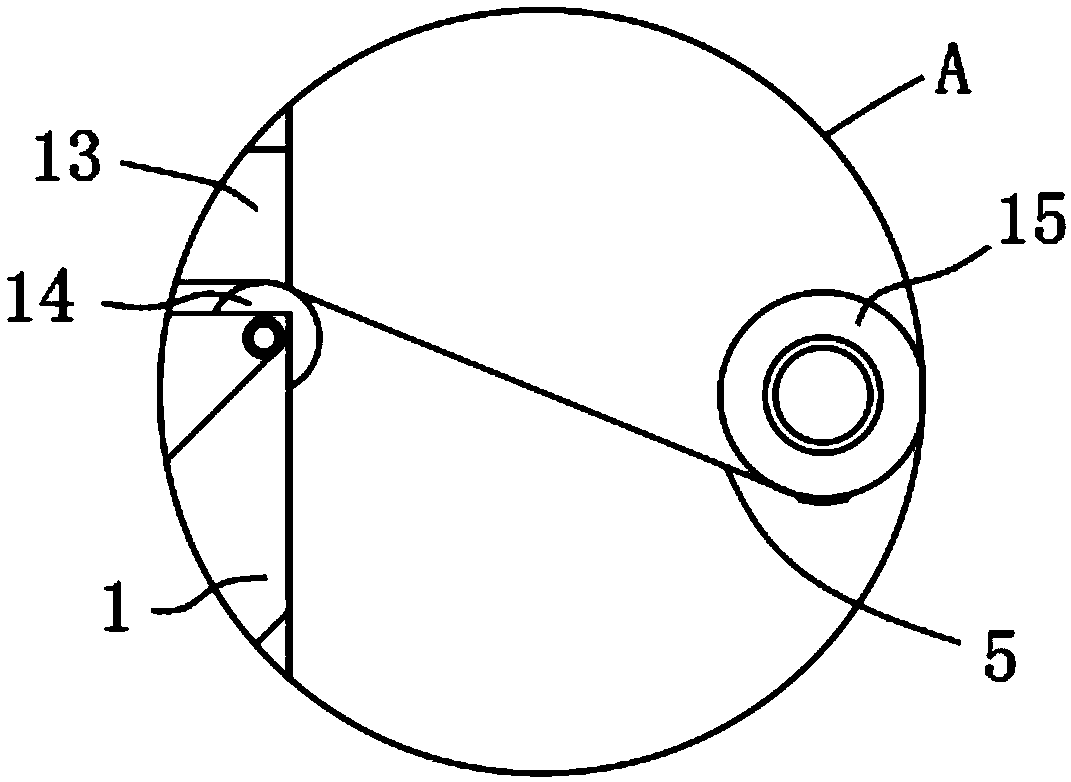

Novel water closet

The invention discloses a novel water closet. The novel water closet comprises a water closet body, wherein installation blocks are symmetrically arranged on the water closet body; the interior of each installation block is provided with a U-shaped notch; a first rotary shaft is arranged in each U-shaped notch, and is rotationally connected with the corresponding U-shaped notch; each first rotaryshaft is fixedly connected with a first rotary roll; the water closet body is rotationally connected with a pre-tightening roll; a water spraying pipe is arranged on the water closet body; the inner wall of the water closet body is fixedly connected with a support block; the support block is rotationally connected with a second rotary roll; the side wall of the water closet body is provided with athrough groove. The novel water closet has the advantages that the direct contact of excrement with water surface is avoided, the splashing is prevented, and the sewage is prevented from splashing tothe human body or outside to cause pollution; by utilizing degrading paper, the difficulty in flushing because of the excrement sticking onto the front and back inner walls of the water closet body is avoided.

Owner:ZHEJIANG ZHENGDA SHUMEIJIA IND & TRADE

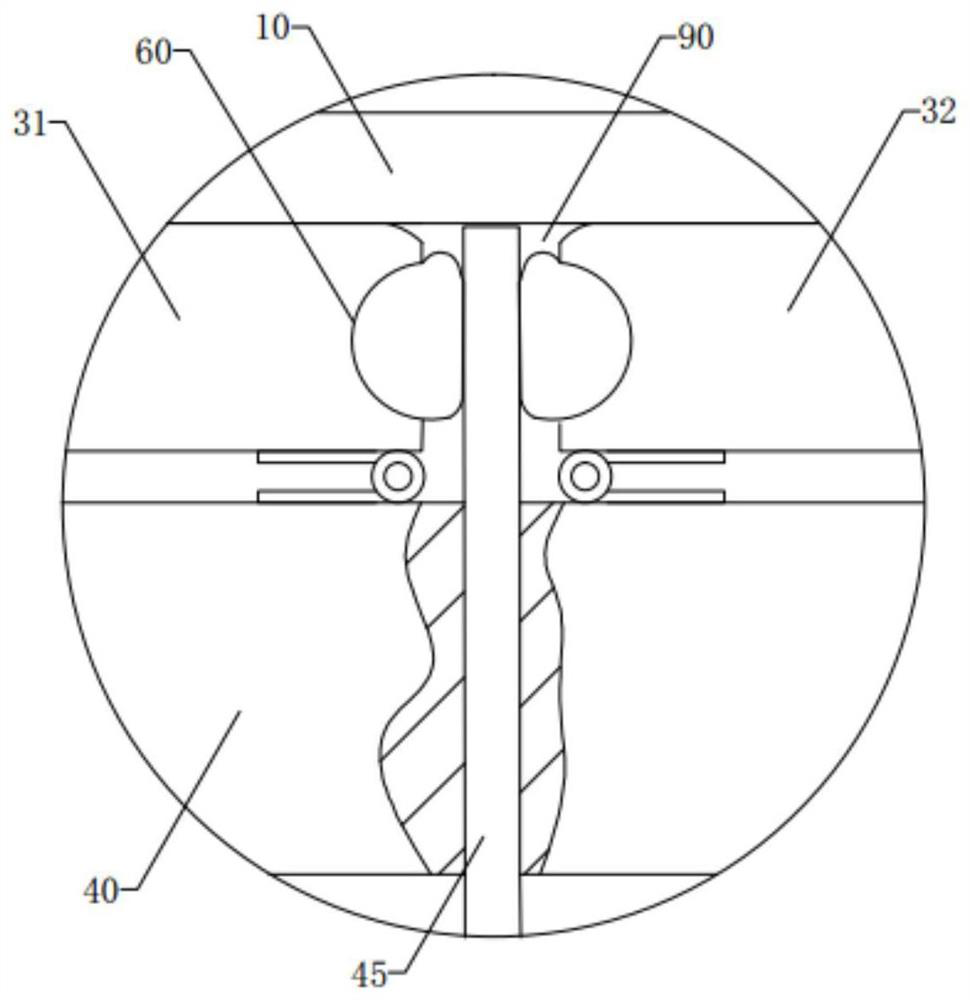

Polishing and cleaning device for mechanical part machining and working method of polishing and cleaning device

ActiveCN114102392AGuaranteed stabilityEasy to achieve grindingGrinding carriagesGrinding drivesMechanical componentsPolishing

The invention relates to the technical field of machining, in particular to a polishing and cleaning device for mechanical part machining and a working method thereof.The polishing and cleaning device comprises a rack and a mounting frame, a fixing mechanism and a recycling mechanism are arranged in the rack, an adjusting mechanism is arranged in a fixing frame, and a polishing wheel is arranged in the fixing frame; in the process of polishing the mechanical part, two servo electric cylinders II push two movable plates to move upwards until connecting plates in the two movable plates are in contact with the bottom of a mounting frame, so that a closed cavity is formed between the mechanical part in the mounting frame and a polishing wheel; on one hand, it is guaranteed that waste chips generated in the grinding process cannot be scattered all around, it is guaranteed that metal waste chips cannot be sputtered in the grinding process, and a certain protection effect on operation safety of operators is achieved, on the other hand, the waste chips generated in the grinding process are conveniently collected and treated in a centralized mode, and the pollution degree of the grinding waste chips to the periphery of the device is reduced.

Owner:广德凯雷特机械科技有限公司

Method for separating elements and solder from waste printed circuit board

InactiveCN103286405BReduce lossesReduce energy consumptionSoldering apparatusPrinted circuit boardEnergy consumption

The invention discloses a method for separating elements and solder from a waste printed circuit board. The method is characterized by including: using brown fused alumina particles as heating media, and using a flat-bottom electric furnace for heating the brown fused alumina particles; and placing a welding surface of the printed circuit board downwards, flatly placing the printed circuit board on the heated brown fused alumina particles, applying vertical downward force to an element surface of the printed circuit board to enable the welding surface to be in full contact with the heated brown fused alumina particles, taking out the printed circuit board after the solder is molten completely, placing the welding surface upwards and the element surface downwards, applying vertical impact force to the welding surface, and enabling the solder and the elements to be separated from the printed circuit board. The method is low in energy consumption, low in cost, high in separating efficiency and good in separating effect.

Owner:HEFEI UNIV OF TECH

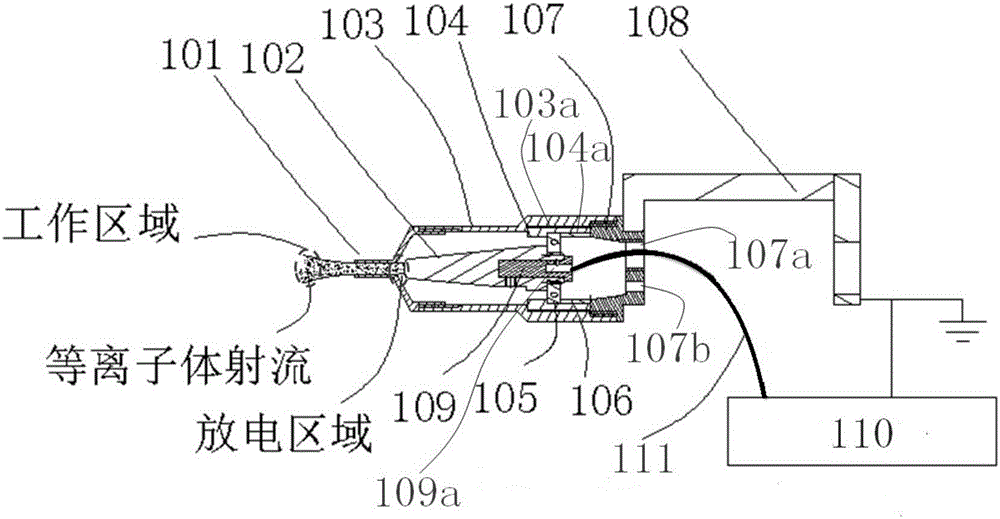

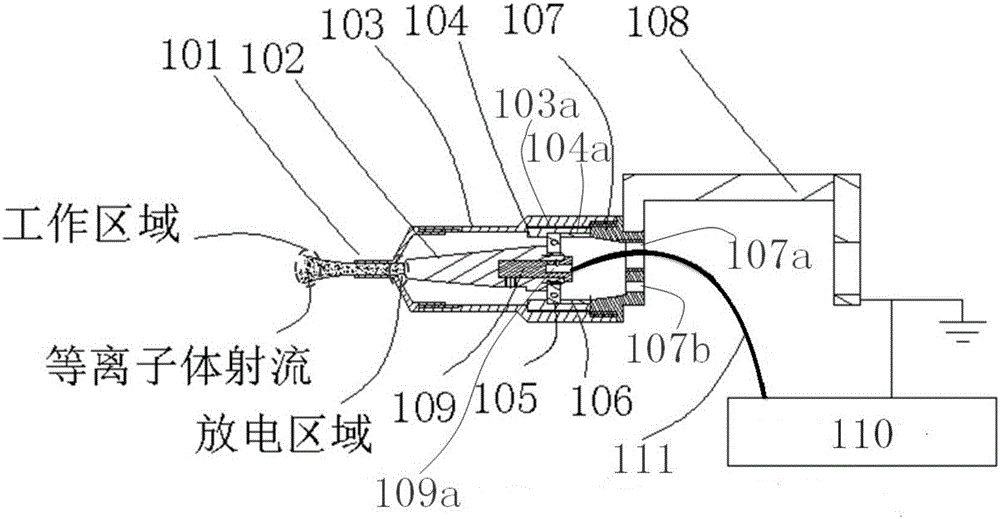

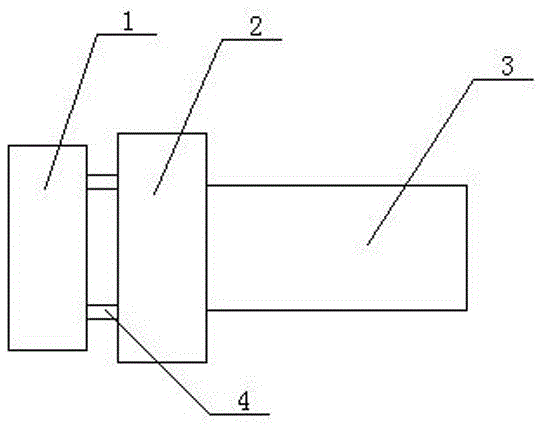

Atmospheric plasma sterilizer used in medical device sterilization apparatus

InactiveCN106581709AGuaranteed mechanical strengthGuaranteed mechanical toughnessDrying gas arrangementsLavatory sanitoryPlasma jetEngineering

The invention provides an atmospheric plasma sterilizer used in a medical device sterilization apparatus. The atmospheric plasma sterilizer comprises a plasma generating power source, a plasma jet head and a mounting member. The mounting member has a C-shaped structure. The plasma jet head is connected to one end of the mounting member. The plasma jet head is connected to one pole of the plasma generating power source through a high voltage insulated cable and the other pole of the plasma generating power source is connected to a mounting table. The plasma jet head comprises a cylindrical casing formed from a nozzle, a head housing and a rear cylinder connected in an order, an inner plasma generating device and an insulating layer between the cylindrical casing and the plasma generating device. The rear cylinder is connected to the mounting member of the plasma sterilizer. The atmospheric plasma sterilizer used in a medical device sterilization apparatus can carry out sterilization and disinfection under atmospheric conditions, does not need a low air pressure environment, and can realize sterilization and disinfection through placement of the surface of a medical apparatus to be treated under injection of a plasma flow.

Owner:合肥优亿科机电科技有限公司

Electrodeless ultraviolet lamp

The invention relates to an electrodeless ultraviolet lamp and belongs to the technical field of an ultraviolet lamp. The electrodeless ultraviolet lamp comprises an external chamber coupler, a quartz lamp bulb and a micro wave generator, wherein a heat conduction tube is arranged between the external chamber coupler and the micro wave generator, and the quartz lamp bulb is internally provided with mercury and inert gas. The electrodeless ultraviolet lamp has advantages of no sputtering phenomenon, good heat radiation, long service life, high efficiency, energy-saving performance, simple structure, reasonable setting and low making cost.

Owner:ANHUI JOYFULL INFORMATION SCI & TECH

Proportion testing and processing equipment based on sweet potato beverage research and development

PendingCN112774483AEasy to dumpNo sputteringRotary stirring mixersTransportation and packagingAgricultural engineeringElectric machinery

The invention provides proportion testing and processing equipment based on sweet potato beverage research and development. The proportion testing and processing equipment based on sweet potato beverage research and development comprises a base and a shell; and the bottom of the shell is fixed to the top of the base, a sliding plate is slidably connected between the two sides of the inner wall of the shell, a plurality of charging boxes are arranged in the sliding plate, and feeding valves are arranged on the front faces of the charging boxes. According to the proportion testing and processing equipment based on sweet potato beverage research and development, a detector is driven to move downwards into a material mixing box for detection through extension of an electric telescopic rod, and a material loading box is driven to move downwards, so that sputtering is avoided when the material loading box discharges materials into a material groove; a first motor drives a first rotating rod to rotate, so that material pouring of the material groove is facilitated, the detector is driven to move rightwards or leftwards, detection of the detector at different positions is facilitated, and the accuracy during detection is improved.

Owner:YINGSHANG TIANHAO FOOD

Industrial wastewater purification equipment

PendingCN113582400AImplement Periodic CollisionsAvoid wastingMultistage water/sewage treatmentTreatment involving sedimentationActivated carbonIndustrial effluent

The invention relates to the technical field of industrial wastewater purification, in particular to industrial wastewater purification equipment which comprises a reaction box, a purification box and a sedimentation tank, box doors are arranged on one side of the reaction box and one side of the purification box, water inlet pipes are symmetrically communicated with the side, away from the purification box, of the reaction box, and a water drainage pipe is communicated with the side, away from the reaction box, of the purification box. The side, away from the purification box, of the sedimentation tank is communicated with a water outlet pipe, a feeding pipe and a motor are arranged on the upper surface of the reaction box, a stirring rod is fixedly installed at the output end of the motor, and an activated carbon plate is arranged in the purification box. According to the invention, through the arrangement of a movable rod, under the transmission action of a belt, through the extrusion action of a driving lever and a convex block, and through cooperation with a pressure spring, the periodic collision of the movable rod to the outer wall of a feeding pipe can be realized, and the vibration of the feeding pipe is caused through the collision action, so that a catalyst attached to the inner wall of the feeding pipe is vibrated down, and the waste of materials is avoided; the subsequent reaction process is fully carried out.

Owner:内蒙古新康环保科技有限公司

Method for separating elements and solder from waste printed circuit board

InactiveCN103286405AReduce lossesReduce energy consumptionSoldering apparatusPrinted circuit boardEnergy consumption

The invention discloses a method for separating elements and solder from a waste printed circuit board. The method is characterized by including: using brown fused alumina particles as heating media, and using a flat-bottom electric furnace for heating the brown fused alumina particles; and placing a welding surface of the printed circuit board downwards, flatly placing the printed circuit board on the heated brown fused alumina particles, applying vertical downward force to an element surface of the printed circuit board to enable the welding surface to be in full contact with the heated brown fused alumina particles, taking out the printed circuit board after the solder is molten completely, placing the welding surface upwards and the element surface downwards, applying vertical impact force to the welding surface, and enabling the solder and the elements to be separated from the printed circuit board. The method is low in energy consumption, low in cost, high in separating efficiency and good in separating effect.

Owner:HEFEI UNIV OF TECH

Circulating ink-injecting neutral pen

The invention discloses a circulating ink-injecting neutral pen, belonging to the neutral pen field. The pen comprises a pen body, a pen head connected with the lower part of the pen body, a pen tip is installed on the pen head, an ink storage chamber is arranged inside the pen body, and the ink storage chamber communicates with the pen tip. A membrane is arranged on the inner wall of the ink storage chamber. The ink storage chamber is provided with a piston, an ink injection nozzle for communicating with the outer wall of the pen body is arranged on the inner wall of the ink storage chamber below the piston, an air bag is arranged in the ink storage chamber above the piston, the air bag is connected with an air valve, a through hole communicating with the ink storage chamber is arranged on the outer wall of the pen body, and the air valve is fixedly installed in the through hole. The invention is reasonable in design and simple in structure, and can not only make the neutral pen circularly used for ink injection, but also prevent ink sputtering when the pen body is fragmented, and prevent ink from sticking and unsmooth descending.

Owner:安徽瀚洋纸品印刷有限公司

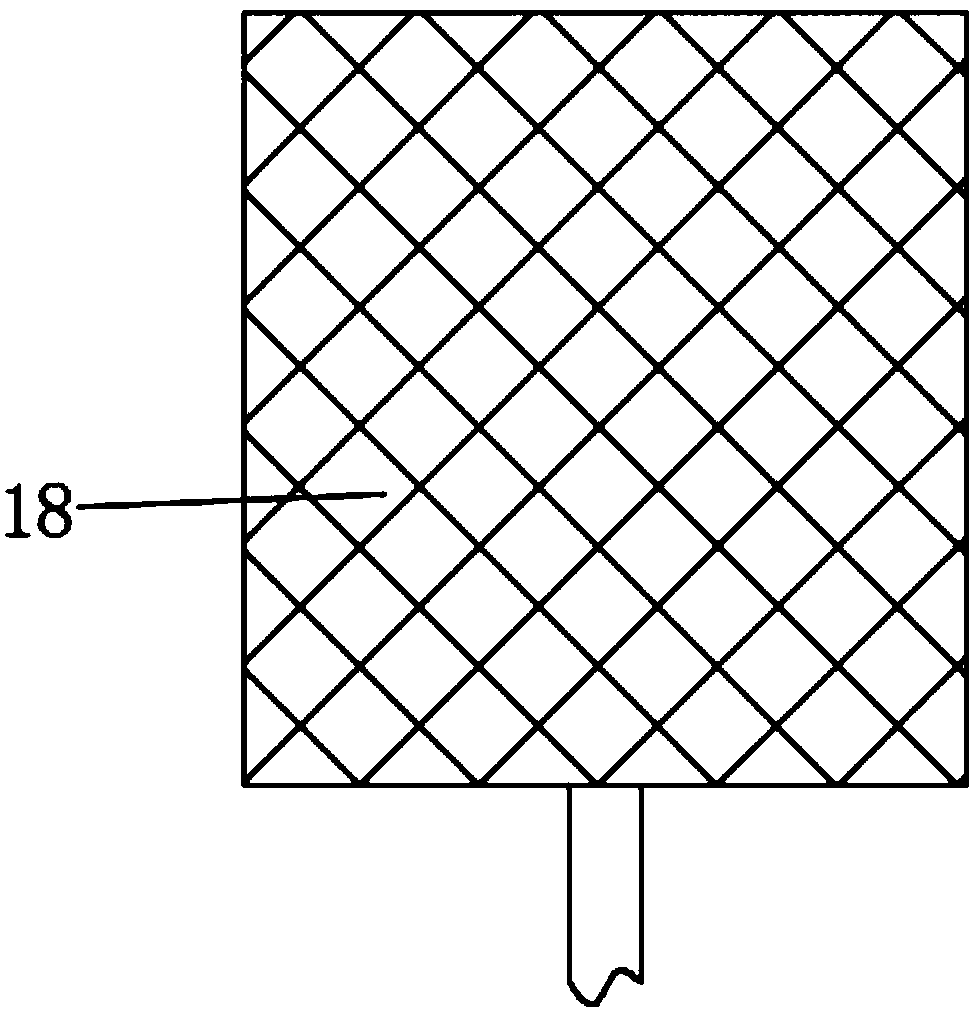

Metal net used for water curtain wall and water flow control method

InactiveCN106918984AOvercoming noise effectsStable and controllable flow rateProjectorsSputteringPorosity

The invention discloses a metal net used for a water curtain wall and a water flow control method. The metal net is formed by serially connecting metal filament spiral structures which are regularly arranged to form water flow pipelines. The porosity of the metal net is that 1a=(1-1b / 1t)*100%, wherein 1b is the volume density of the metal net and 1t is the true density of the metal net. The height range of the metal net is 1m-50m, the wide range is 1m-50m and the metal net is made of stainless steel 316. According to the invention, by regularly arranging the metal filament spiral structures to form the water flow pipelines, water flows downwards stably at stable and controllable flow speed without noise and sputtering in the 90-degree vertical condition largely. By slowing down and controlling speed of water flows, a water flow noise reducing effect is achieved. The metal net can be matched with light, so the surface is bright and colorful, clearly layered and quite stereo, and rhythm effects are quite remarkable. The metal net can be used as projection curtain with clear images and high color resolution and can replace an electronic tube screen.

Owner:上海瀑之源景观工程有限公司

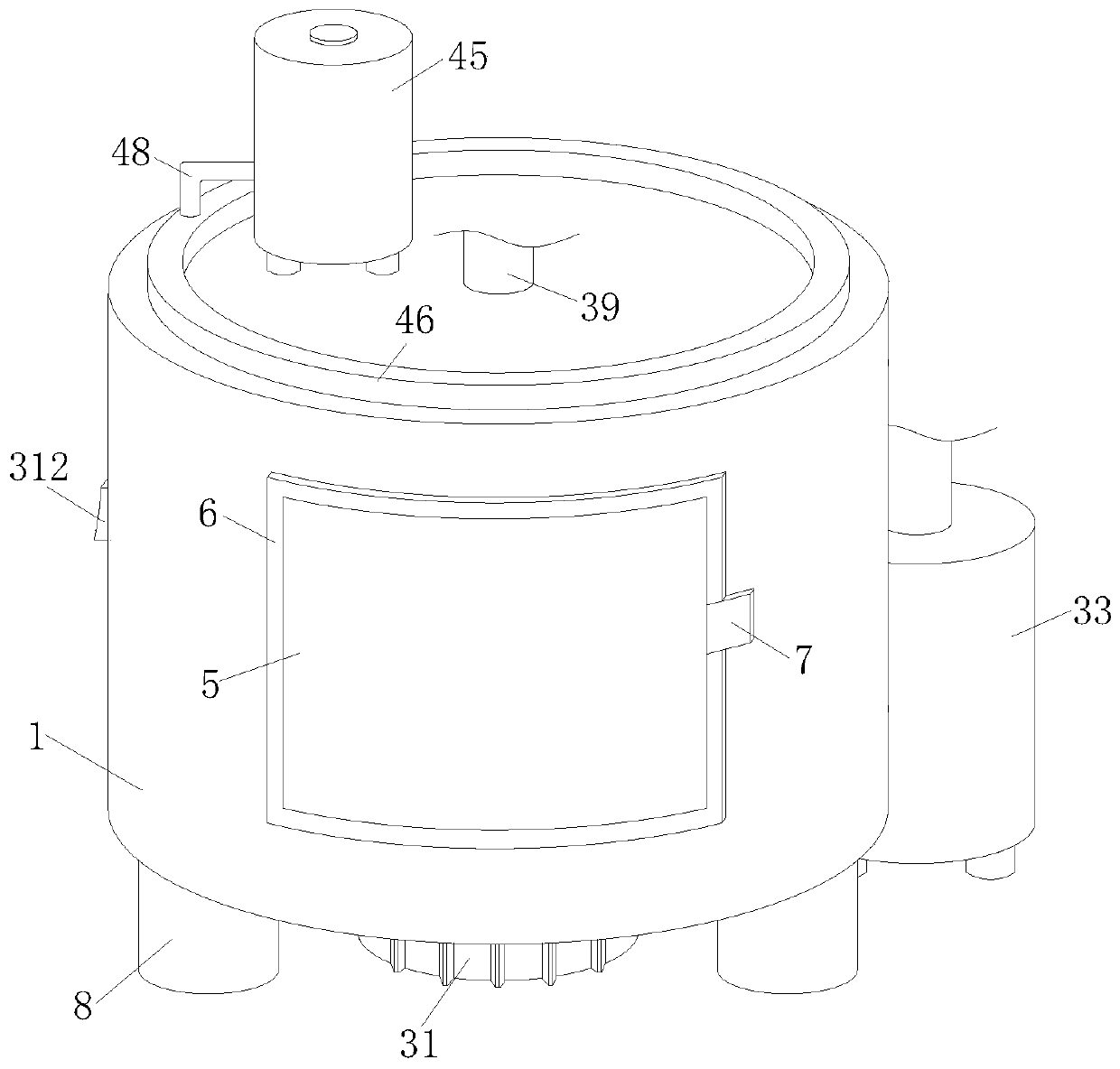

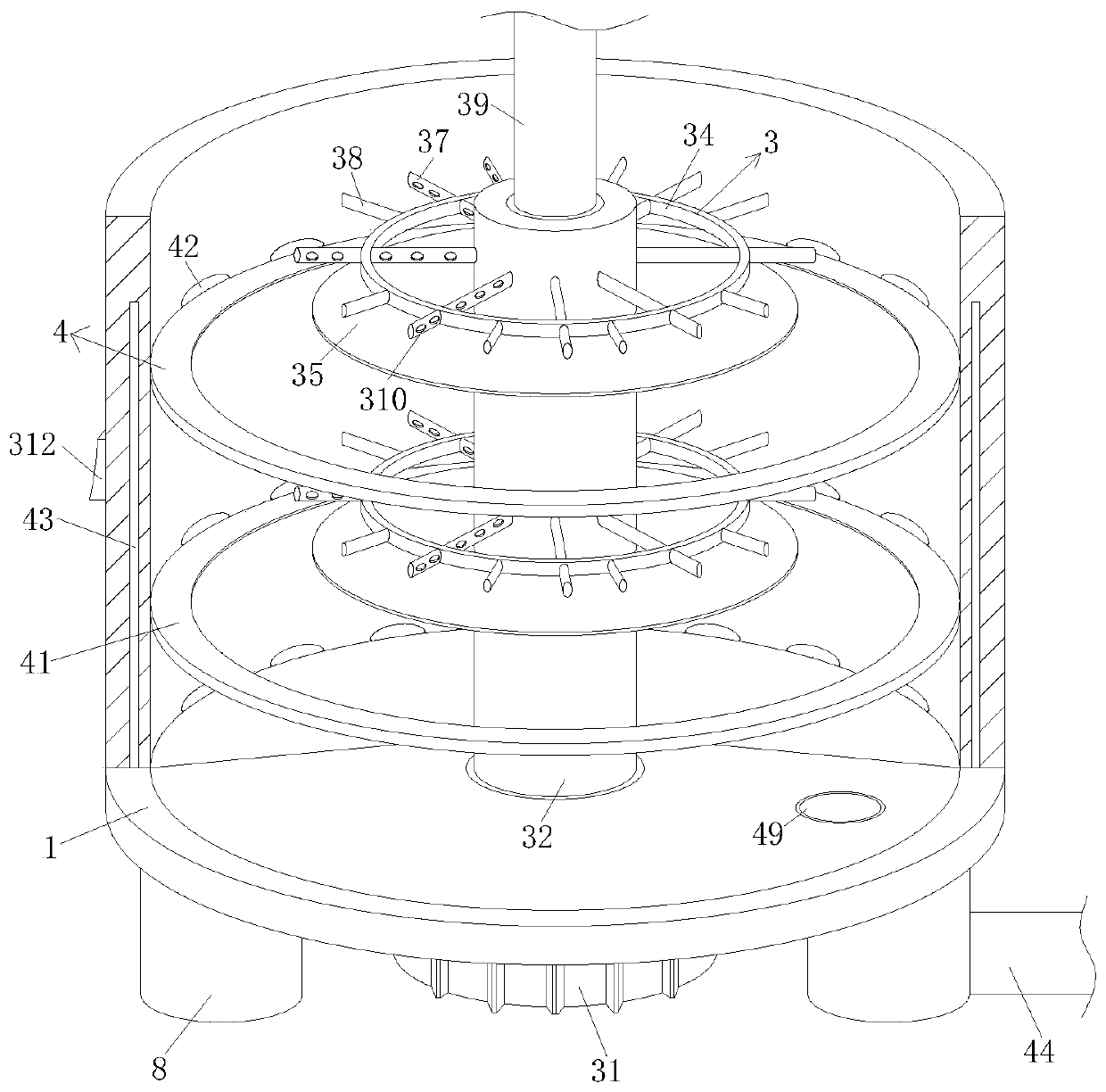

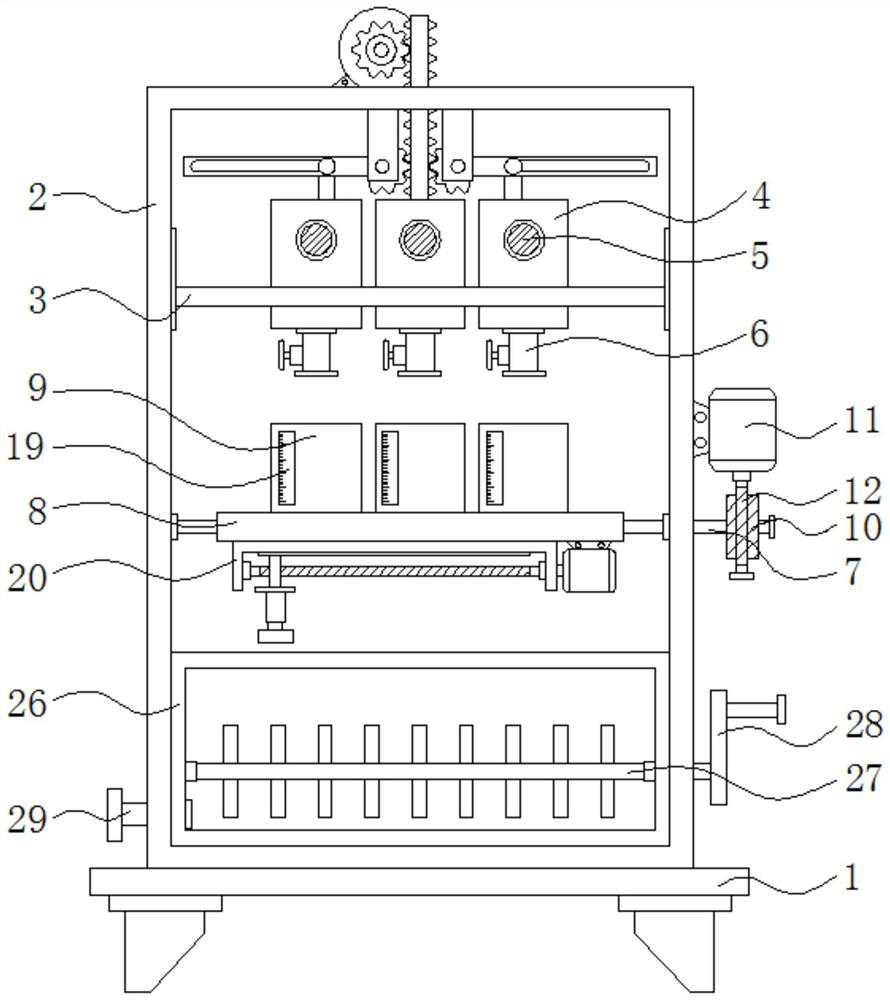

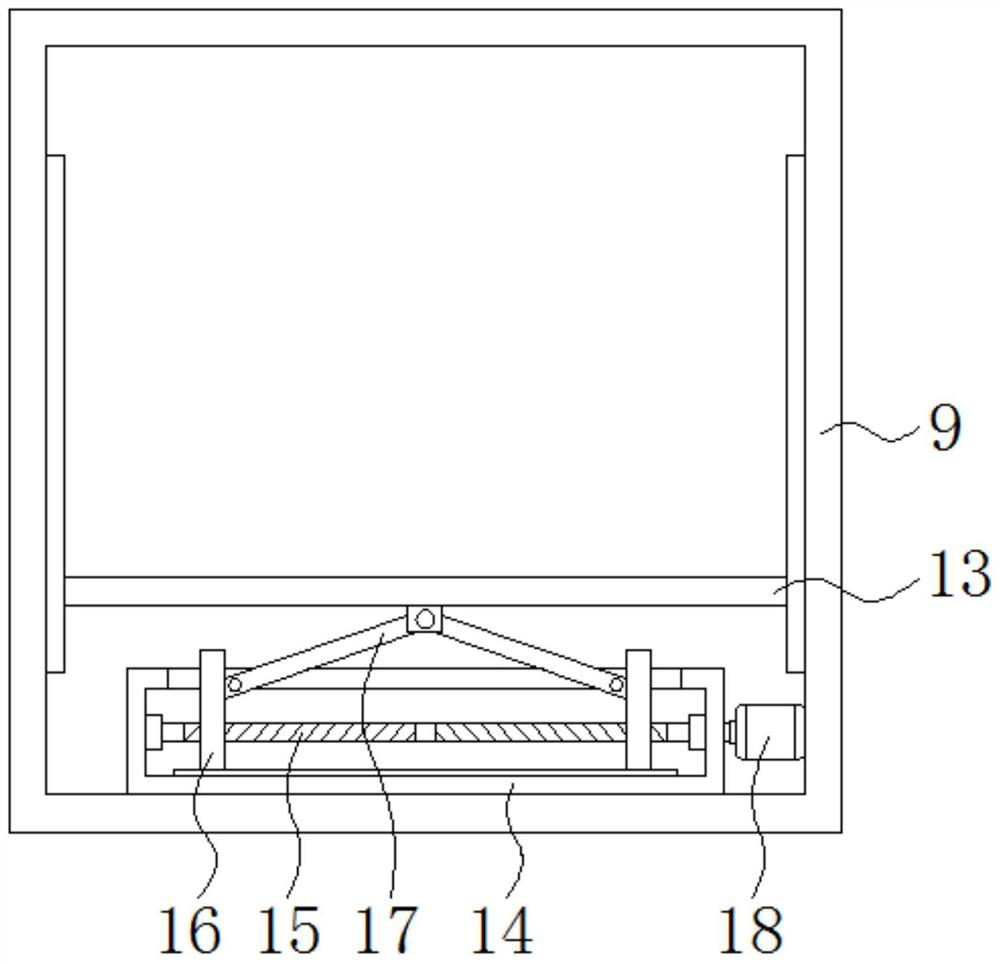

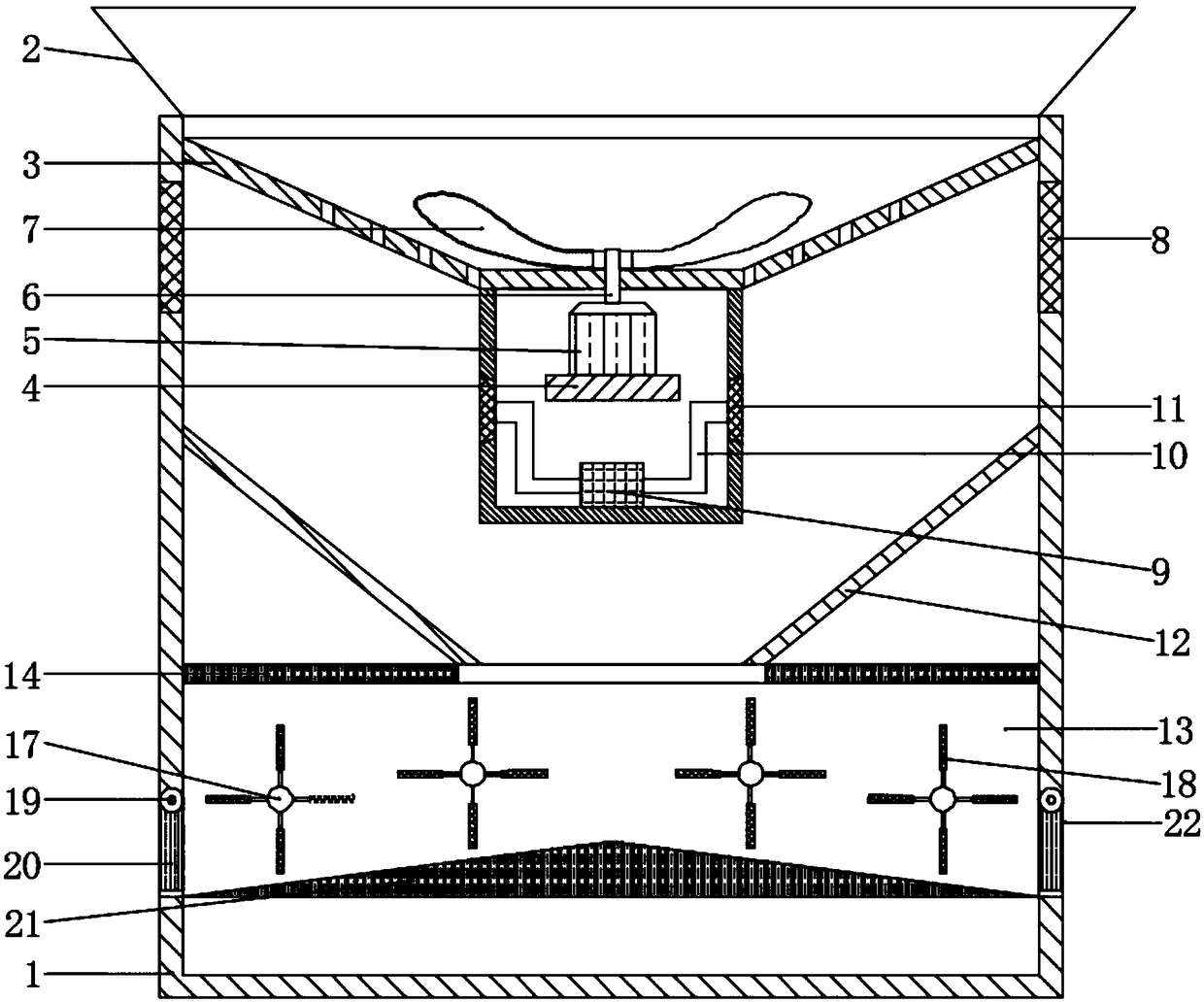

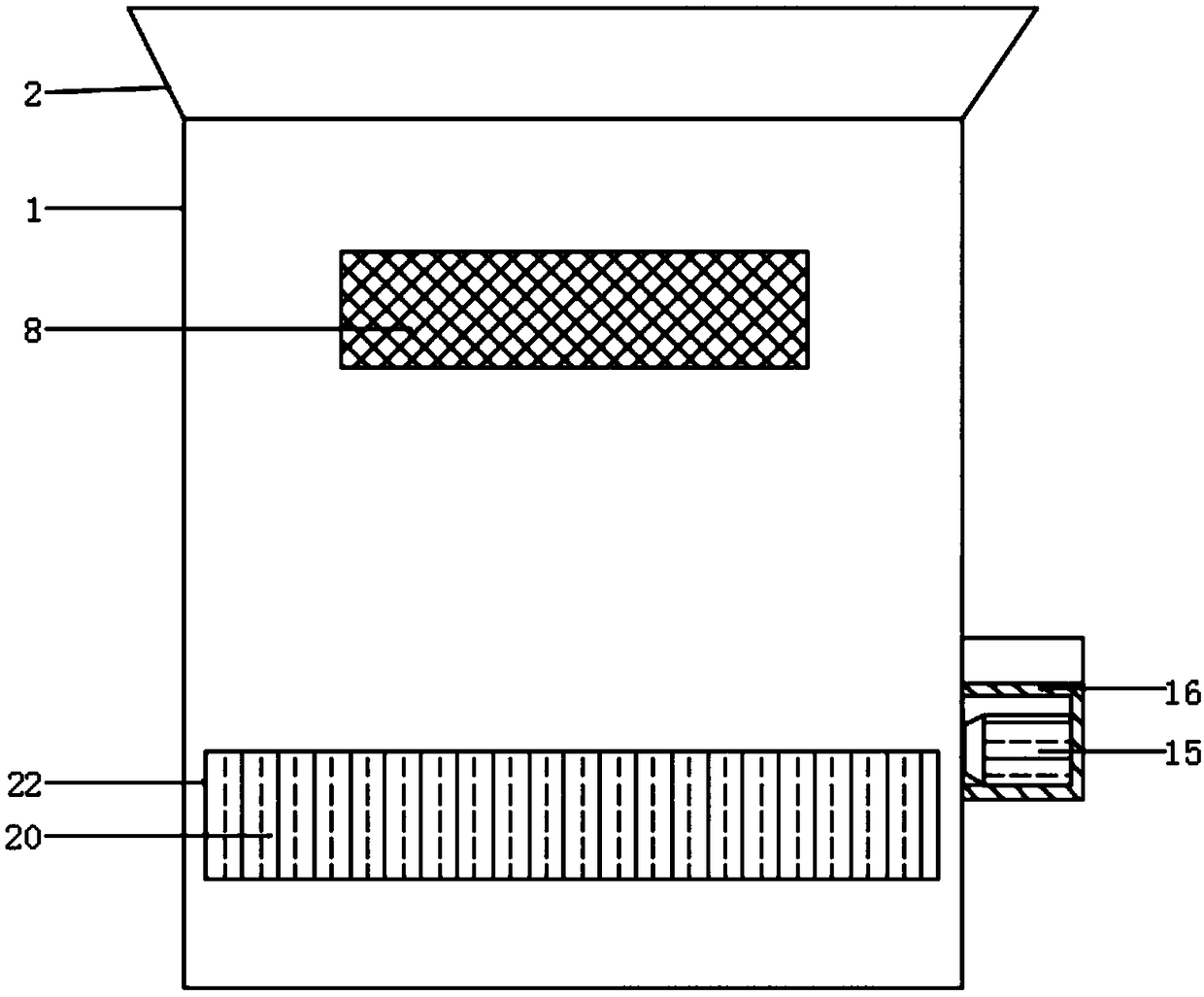

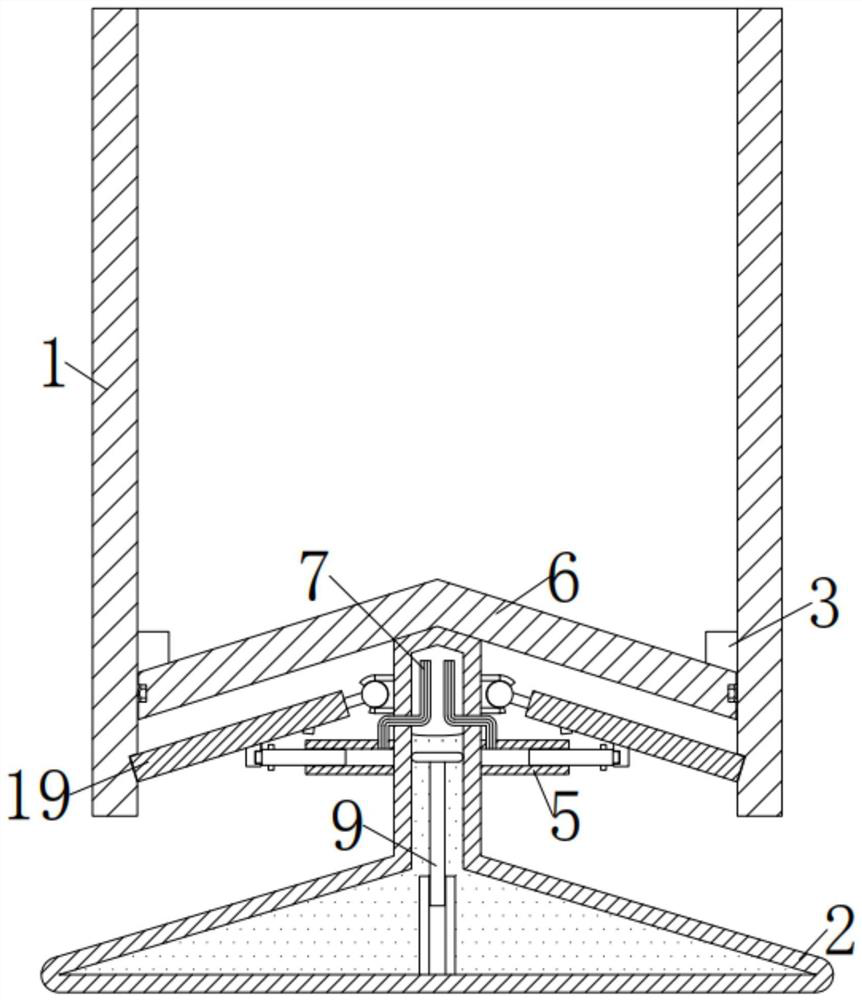

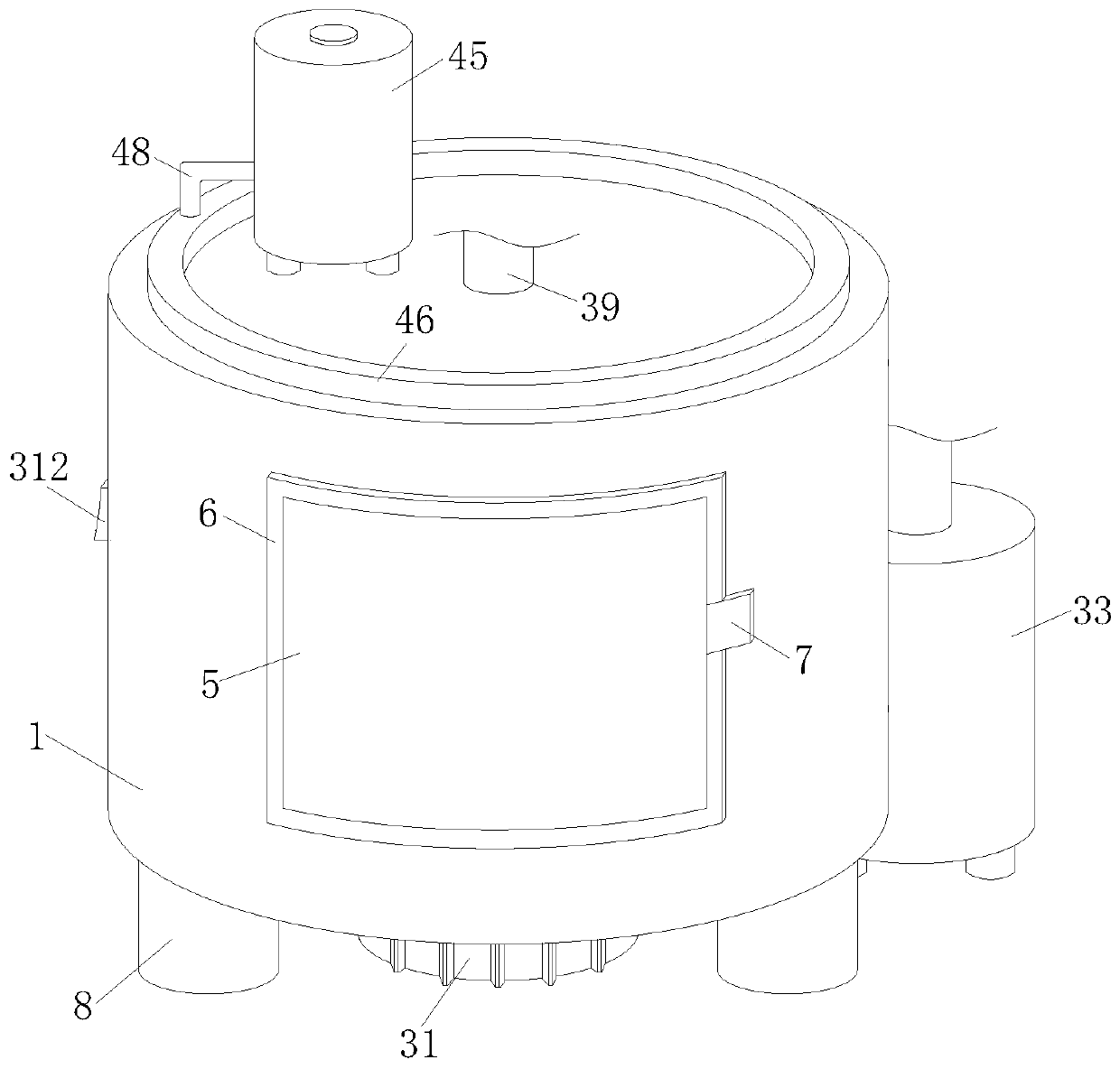

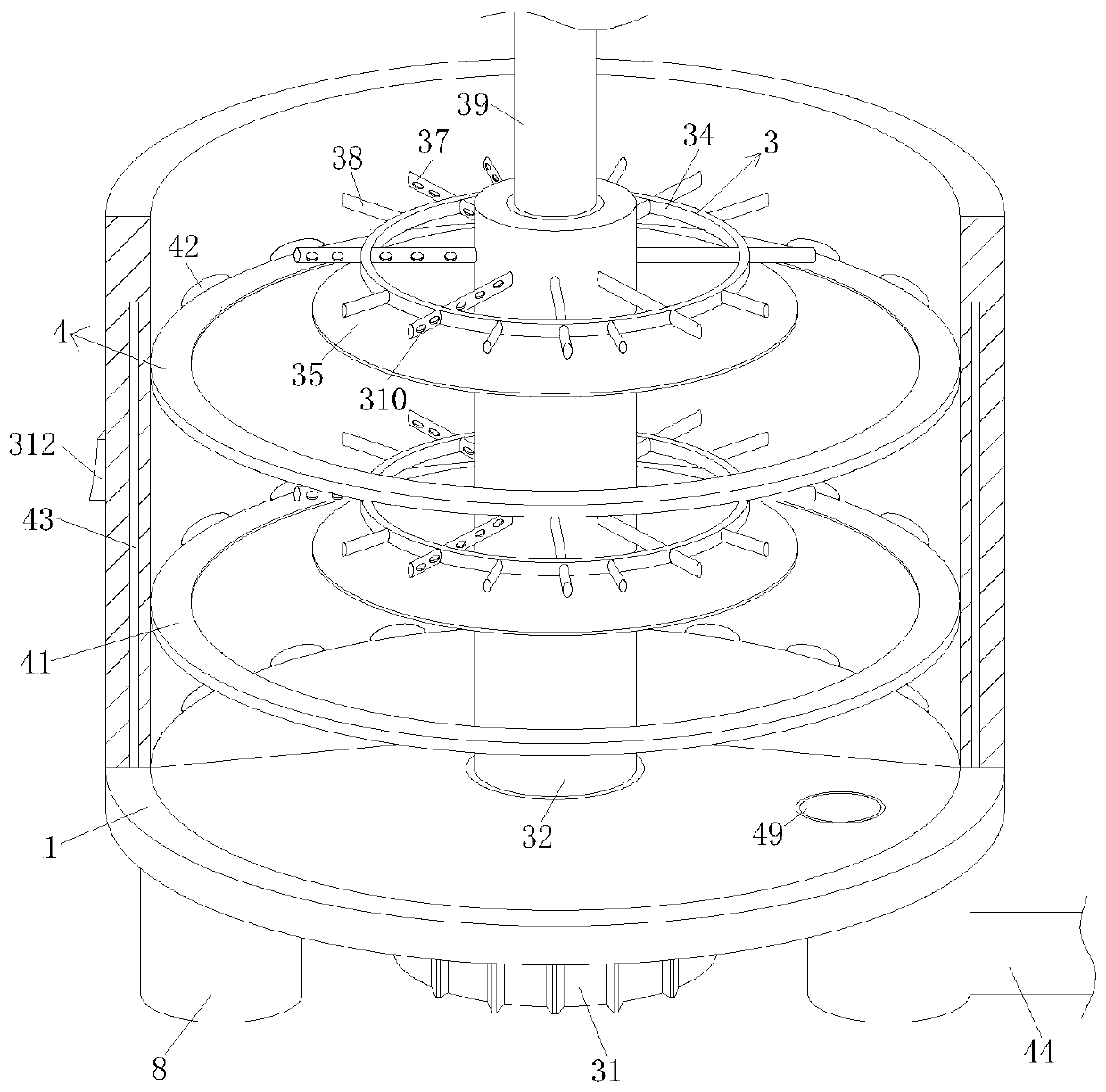

Multi-level cereal drying device

InactiveCN109307421ANo sputteringEfficient dryingDrying gas arrangementsDrying solid materialsMechanical engineeringGrain drying

The invention discloses a multi-level cereal drying device. The multi-level cereal drying device comprises a box body, a cereal feeding hopper, a discharging plate, ventilation ports, a conical cylinder, a drying cavity, a drying unit, a second stirring device, installing bases, baffles, discharging ports and a motor chamber. The cereal feeding hopper is arranged on the box body. The discharging plate is arranged below a top plate of the box body. A through hole is formed in the discharging plate. The motor chamber arranged on the inner wall of the box body is arranged below the discharging plate. The ventilation ports are formed in the left side face and the right side face. The conical cylinder is arranged on the inner wall of the interior of the box body. The lower end of the conical cylinder communicates with the drying cavity provided with the drying unit. The second stirring device is arranged in the drying cavity. The installing bases are arranged at the upper ends of the discharging ports. The baffles are movably arranged on the installing bases. The multi-level cereal drying device is excellent in practical effect, accumulation is not generated in the drying process, cereal drying is rapid and efficient due to multi-level drying, and splashing is not generated during cereal discharging through the baffles.

Owner:湖南米笠农业科技有限公司

A new type of toilet

The invention discloses a novel water closet. The novel water closet comprises a water closet body, wherein installation blocks are symmetrically arranged on the water closet body; the interior of each installation block is provided with a U-shaped notch; a first rotary shaft is arranged in each U-shaped notch, and is rotationally connected with the corresponding U-shaped notch; each first rotaryshaft is fixedly connected with a first rotary roll; the water closet body is rotationally connected with a pre-tightening roll; a water spraying pipe is arranged on the water closet body; the inner wall of the water closet body is fixedly connected with a support block; the support block is rotationally connected with a second rotary roll; the side wall of the water closet body is provided with athrough groove. The novel water closet has the advantages that the direct contact of excrement with water surface is avoided, the splashing is prevented, and the sewage is prevented from splashing tothe human body or outside to cause pollution; by utilizing degrading paper, the difficulty in flushing because of the excrement sticking onto the front and back inner walls of the water closet body is avoided.

Owner:ZHEJIANG ZHENGDA SHUMEIJIA IND & TRADE

High frequency brazing machine

ActiveCN104174960BImprove qualityReduce precisionHeating appliancesSoldering auxillary devicesEddy currentEngineering

The invention discloses a high-frequency brazing machine which comprises a worktable, a vacuum system component and a cooling component. A welding work box, a high-frequency generator, a programmed control device and a temperature detection component are arranged on the worktable, a work fixture and a high-frequency magnetic bar coil are arranged in the welding work box, the work fixture fixes a workpiece to be welded, a pneumatic drive workpiece is arranged at one end of the welding work box and connected with the work fixture and drives the work fixture to run, and the programmed control device is connected with the vacuum system component, the pneumatic drive workpiece, the high-frequency generator, the cooling component and the temperature detection component. By the mode, the high-frequency brazing machine realizes brazing by the aid of eddy current, safety can be guaranteed, and the high-frequency brazing machine is low in risk and cost, high in efficiency and fine in welding performance.

Owner:CHANGSHU JUNCHI SCI & TECH

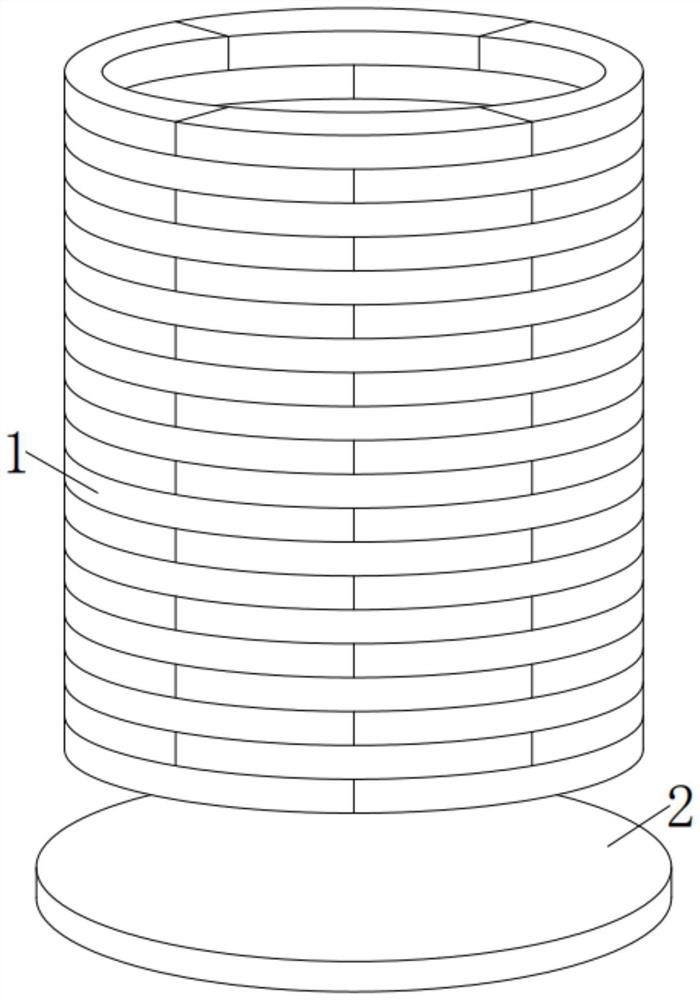

Tungsten bar stacking crucible for intermediate frequency furnace

The invention discloses a tungsten bar stacking crucible for a intermediate frequency furnace. The tungsten bar stacking crucible comprises a pot body and a supporting cylinder, wherein the pot body is formed by stacking and assembling a plurality of stacked tungsten bars, and an upper portion and a lower portion of the pot body are open; the supporting cylinder is arranged below the pot body; a limiting ring is fixed to an inner wall of the pot body; a blocking disc is fixed to the top of the supporting cylinder; the blocking disc is slidably arranged on the inner wall of the pot body and abuts against the bottom of the limiting ring; and a plurality of sleeves and a plurality of expansion blocks are fixed to a side face of the top of the supporting cylinder. According to the invention, the supporting cylinder is filled with mercury, the mass of the supporting cylinder and the mass of the mercury are very large, the gravity center of the whole pot body moves downwards, and the bottom of the pot body is very stable, so that the pot body stands stably and is high in safety; the mercury is cooled in the supporting cylinder, and the volume of the mercury is reduced, so that negative pressure is generated in the supporting cylinder, a communicating pipe and a telescopic cylinder; a telescopic rod is contracted into the telescopic cylinder, so that a clamping head and a clamping sleeve are separated; and a clamping rod is not supported and inclines downwards, so that the blocking disc can be detached from the interior of the pot body, high-temperature liquid metal can be poured out from the bottom of the pot body, and the use safety is very high.

Owner:赣州海盛钨业股份有限公司

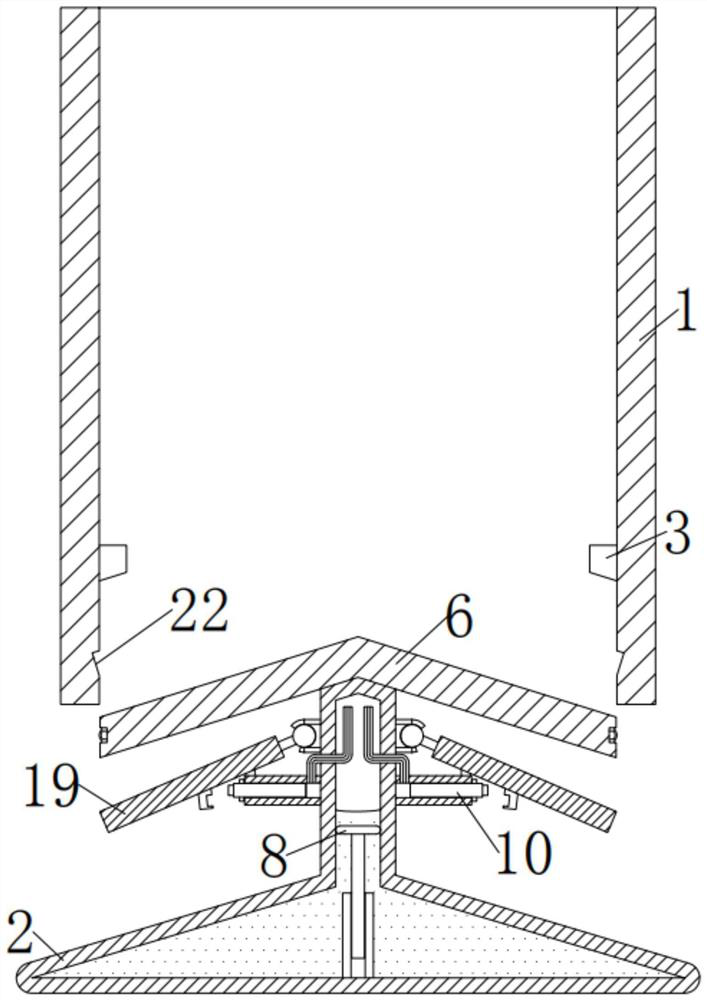

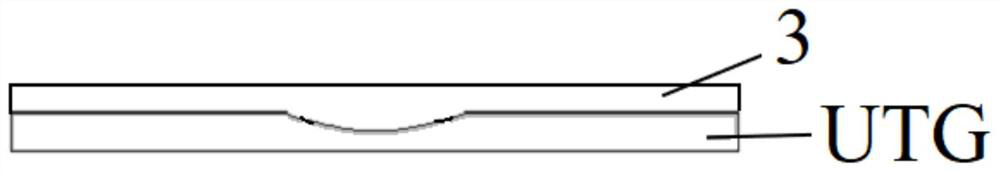

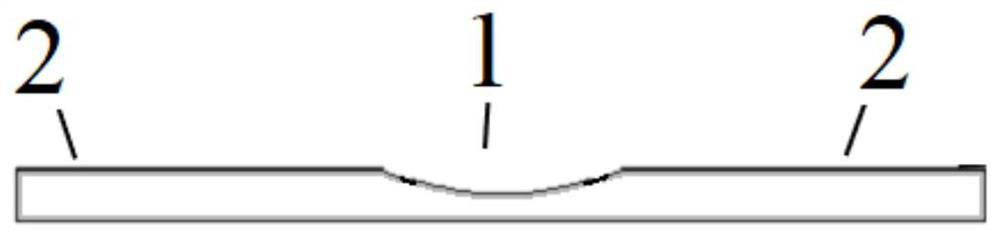

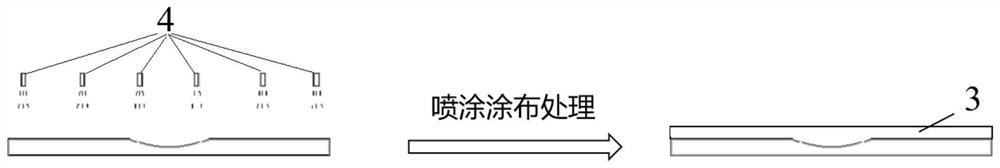

Ultrathin flexible cover plate and preparation method thereof

PendingCN113194170AImprove bending performanceHigh strengthTelephone set constructionsSputteringStructural engineering

An ultrathin flexible cover plate disclosed by the present invention comprises a UTG and a polymeric membrane layer arranged on the UTG, the UTG comprises two equal-thickness regions and a non-equal-thickness region located between the two equal-thickness regions, the thickness of the equal-thickness regions is uniform, the non-equal-thickness region is provided with a maximum-thickness piece and a minimum-thickness piece, the thickness of the maximum-thickness piece is uniform, and the thickness of the minimum-thickness piece is uniform. And the thickness of the non-uniform thickness region is gradually increased from the minimum thickness piece to the maximum thickness piece. According to the ultrathin flexible cover plate disclosed by the invention, the bending performance and the strength of the ultrathin flexible cover plate can be improved by arranging the uniform-thickness regions and the non-uniform-thickness regions, so that the product quality is improved; and when the cover plate is bent and broken, glass fragments still adhere to the polymeric membrane layer, the phenomenon of sputtering of the tempered glass is avoided, the harm of the tempered glass to the human body can be effectively prevented, and a great contribution is made to the development of the flexible screen mobile phone. The invention also discloses a preparation method of the ultrathin flexible cover plate.

Owner:芜湖东信光电科技有限公司

Aluminum scrap recovering, transferring and melting tank

InactiveCN105349784ASimple structureReasonable designProcess efficiency improvementMelting tankGraphite

The invention discloses an aluminum scrap recovering, transferring and melting tank. The aluminum scrap recovering, transferring and melting tank comprises a melting tank body. The melting tank body comprises a guiding-in end, a discharging end and a stirring elevator. The guiding-in end is provided with an aluminum scrap inlet, a molten aluminum lifting opening and a first pipeline. The discharging end comprises a molten aluminum outlet and a second pipeline. The stirring elevator comprises a graphite blade rotor. The graphite blade rotor stretches into the molten aluminum lifting opening and used for extracting high-temperature molten aluminum and discharging the extracted high-temperature molten aluminum out of the first pipeline. The high-temperature molten aluminum discharged into the first pipeline is discharged out of the aluminum scrap inlet through the first pipeline, then the molten aluminum is in a vortex shape and is discharged into the melting tank, and aluminum scraps to be recovered are poured out from the aluminum scrape inlet at the same time and enter the melting tank along with the molten aluminum. The aluminum scrap recovering, transferring and melting tank has the characteristics that the aluminum scraps are guided into the melting tank smoothly, the melting effect is good, and the high-temperature molten aluminum is collected easily. The stirring elevator has the characteristics of being resistant to high temperature, good in heat dissipation performance and high in lifting efficiency. In addition, the maintenance difficulty of the tank is low, assemblies can be independently replaced, the maintenance cost is low, and meanwhile the risk coefficient of aluminum scrap melting and recovering is decreased accordingly.

Owner:ZHENJIANG YUJIU INTELLIGENT EQUIP LTD BY SHARE LTD

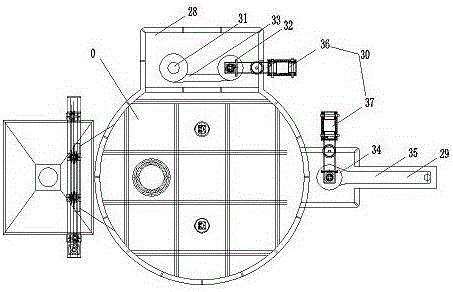

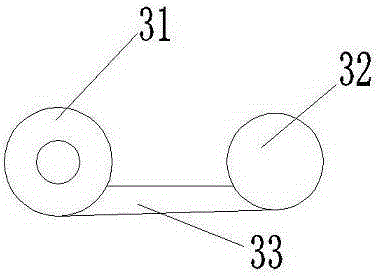

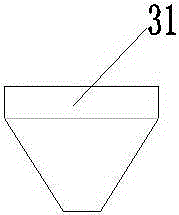

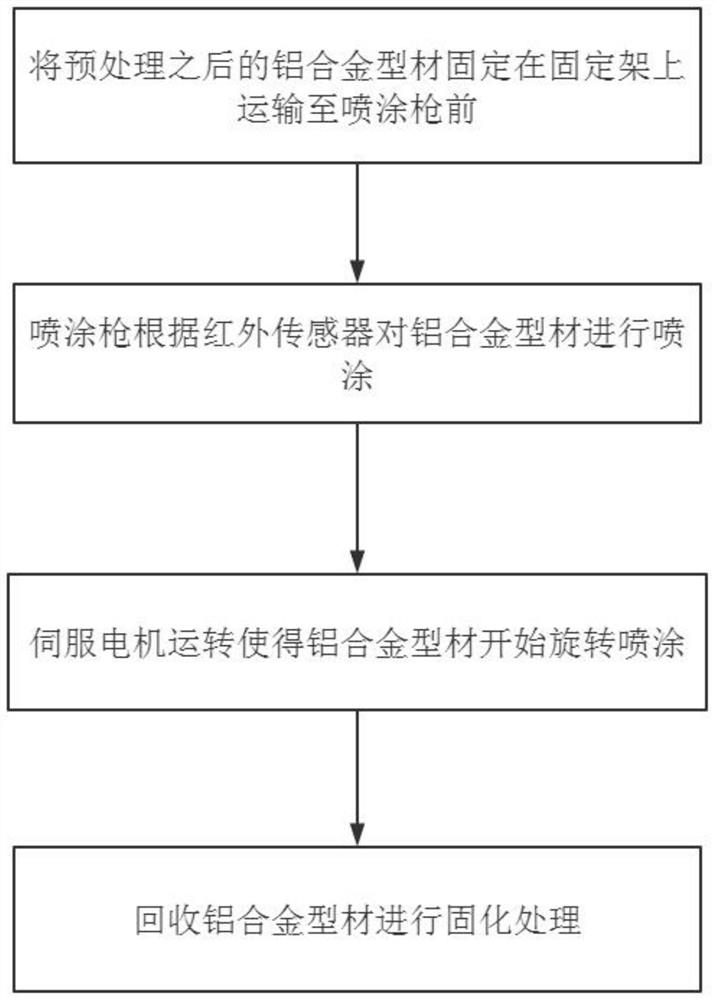

Suspension device for aluminum alloy profile spraying and spraying method

The invention discloses a suspension device for aluminum alloy profile spraying and a spraying method, and relates to the technical field of suspension spraying. The problem that an aluminum alloy profile cannot be sprayed in all directions is solved. The method specifically comprises the following steps that a pretreated aluminum alloy profile is fixed to a first electric guide rail and transported to the position in front of a spraying gun, the spraying gun sprays the aluminum alloy profile according to an infrared sensor, a servo motor operates and enables the aluminum alloy profile to start rotating spraying, and the aluminum alloy profile is recycled for curing treatment. Electric push rods are arranged on a fixing frame, firstly, the longitudinal electric push rods push fixing plateson the upper side and the lower side to fix the aluminum alloy profile, at the moment, the transverse electric push rods are in a contraction state, the contact area with the aluminum alloy profile is increased through the fixing plates, and therefore friction force is improved, the fixing effect of the aluminum alloy profile is better, the suspension device can fix the aluminum alloy profile with complex shapes, and the application range of the device is widened.

Owner:肖述虎

An environmentally friendly battery manufacturing machinery and equipment

ActiveCN110993540BDrying will not affectNo vibrationFinal product manufactureSemiconductor/solid-state device manufacturingCell fabricationProcess engineering

Owner:广州爱邦建筑科技有限公司

a creasing machine

InactiveCN109514917BQuality assuranceFast absorptionPaper-makingBox making operationsPaperboardStructural engineering

The invention relates to the technical field of paper product machining equipment, in particular to an indenting machine. The indenting machine comprises a machine frame and an upper indenting cutterused for indenting, and further comprises a first releasing plate and a second releasing plate which are connected with the machine frame; an indenting groove is formed between the first releasing plate and the second releasing plate and located below the upper indenting cutter; an elastic hose is arranged in the indenting groove and provided with a plurality of vapor outlets, and water vapor is injected into the elastic hose; the first releasing plate and the second releasing plate can be folded and are hinged to a slide table; and a lower indenting cutter is arranged in the indenting groove,slidably connected with the slide table and connected to a driving device. According to the indenting machine, a paperboard is wetted through the water vapor, the lower indenting cutter extrudes theindented back surface preliminarily, indentations are generated on the indented back surface so that tension can be reduced, indenting is conducted in the releasing plate folding mode, the problem that in the prior art, water sprayed during paperboard indenting is prone to splashing and flowing is solved, cracking of the back surface of the paperboard is prevented, and the indenting quality is improved.

Owner:重庆朝旭印务有限公司

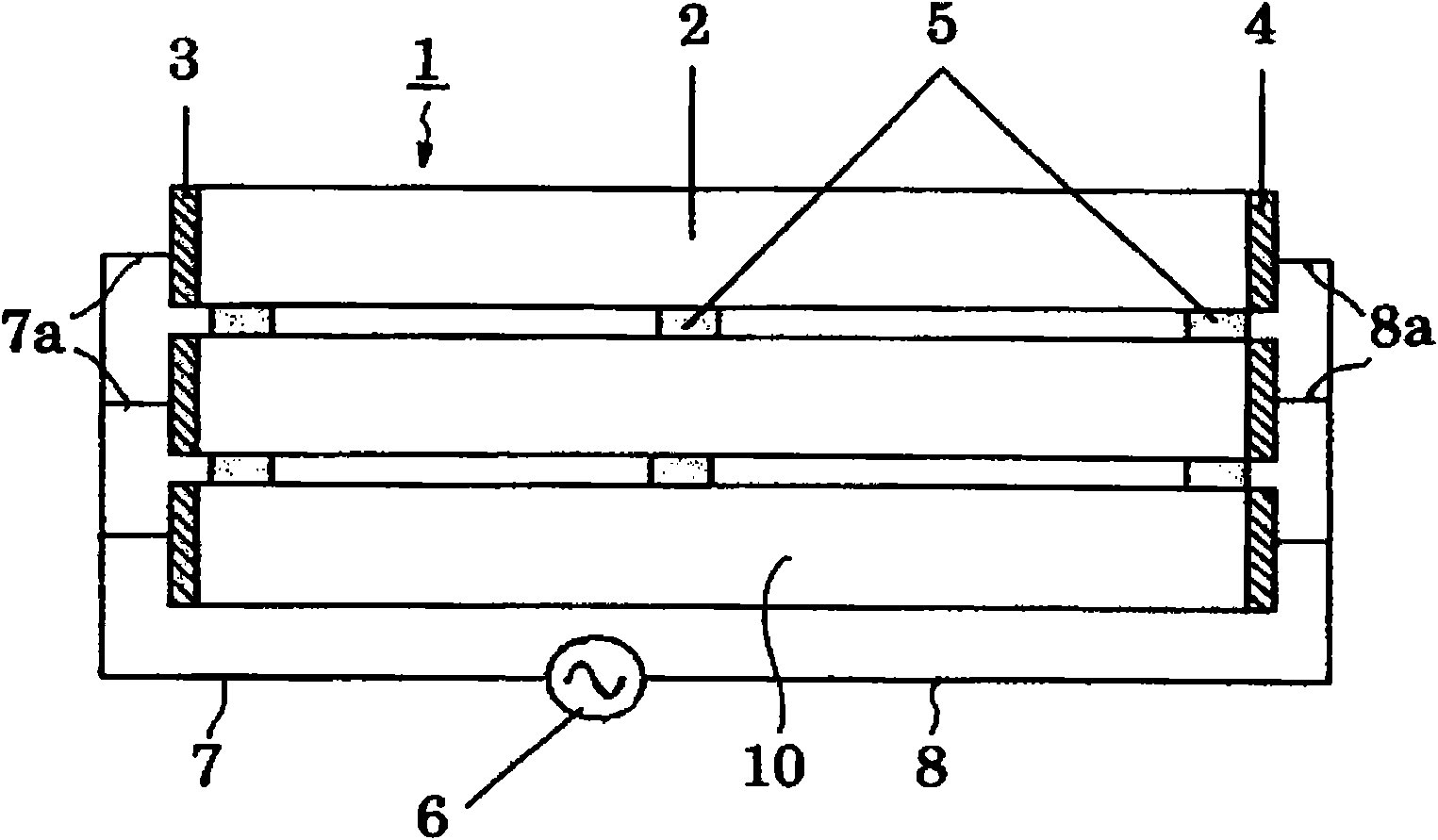

Power saving highl luminance integrated fluorescent lamp

ActiveCN101952642AImprove cooling effectImprove heat retentionElongate light sourcesElectric lightingFluorescenceEngineering

An integrated fluorescent lamp is provided with fluorescent lamp tube groups which are bundle-arranged by making tube axes parallel, a spacer separating adjacent fluorescent lamp tubes at prescribed intervals, and a parallel connection part connecting the fluorescent lamp tube groups in parallel. Electrodes on both ends of the fluorescent lamp tube are constituted of discharge space insulation-type electrodes which are electrically insulated from an inner discharge space. When high frequency voltage is applied to the parallel connection parts at both ends, discharge gas is ionized on electrons and positive ions, and a third generation electron source (called just as electron source) and a positive ion source are formed near the discharge space insulation-type electrodes. The fluorescent lamp tubes can be kept to 40 to 45 DEG C being a discharge optimum temperature by installing a heat keeping tube surrounding the integrated fluorescent lamp and heat keeping end pars at upper and lower ends. Even if all the tubes are simultaneously lighted, power consumption can be reduced and high luminance emission proportional to the number of tubes is realized. When the third generation electron source is used, the problem of electrode voltage drop and sputtering is solved.

Owner:北京千树万树互联网科技有限公司

Method for spraying tin on pole plate

ActiveCN108365180ANo sputteringAvoid wastingElectrode carriers/collectorsLead-acid accumulator electrodesManufacturing technologyEngineering

The invention discloses a method for spraying tin on a pole plate, belonging to the technical field of grid manufacturing. The method comprises the following steps: step 1, putting a heating barrel ina storage barrel and putting tin blocks into the heating barrel; step 2, starting a first motor to drive the rotation of the heating barrel and adjusting temperature; step 3, putting liquid tin intothe storage barrel, starting a second motor to drive synchronous rotation of the storage barrel with the heating barrel, and beginning conveying of the grid via a conveyor belt; step 4, when the gridis conveyed to the storage barrel, subjecting the grid to blowing for dusting; step 5, after blowing dusting of the grid, pressing liquid tin out along with brush hair in virtue of pressure formed ina tin brush, and evenly spraying tin on the grid by using the brush hair; and step 6, after uniform spraying of tin on the grid, pressing the liquid tin on the grid via the storage barrel, and then carrying the grid away via the conveyor belt to complete tin spraying. According to the invention, is heating is carried out during tin spraying on the grid, so liquid tin is prevented from solidification and uniform tin spraying on the grid is guaranteed.

Owner:GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com