Aluminum scrap recovering, transferring and melting tank

A technology for melting pools and aluminum scraps, applied in the direction of improving process efficiency, can solve the problems of safety hazards for workers, high temperature aluminum liquid sputtering hazards, high temperature aluminum liquid sputtering and other problems, and achieves low maintenance difficulty, good melting effect, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

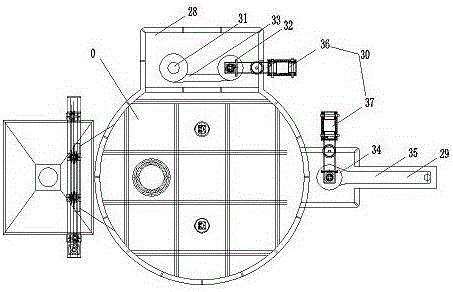

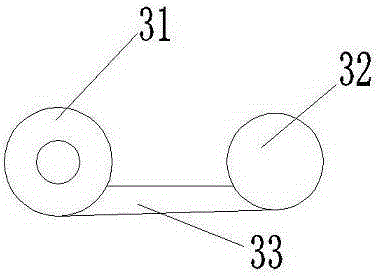

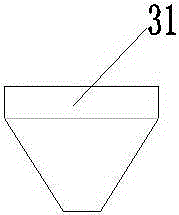

[0024] As shown in the figure, a melting pool for recycling and conveying aluminum shavings is characterized in that it includes a melting pool main body 0, and the melting pool main body 0 includes an introduction end 28, a discharge end 29 and a stirring hoist 30, and the introduction end 28 is set There are aluminum chip inlet 31, aluminum liquid lifting port 32 and first pipeline 33, and the discharge end 29 includes aluminum liquid outlet 34 and second pipeline 35, and described aluminum chip inlet 31 and aluminum liquid lifting port 32 pass through first pipeline 33 connected, the aluminum chip inlet 31 is in the shape of a conical funnel, the aluminum liquid outlet 34 communicates with the second pipeline 35, the stirring elevator 30 includes a first stirring elevator 36 and a second stirring elevator 37, and the first A stirring hoist 36 is arranged at the lifting mouth 32 of the molten aluminum, and the second stirring hoist 37 is arranged at the outlet 34 of the molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com