Mildew-proof treatment method for flat glass

A flat glass and anti-mold treatment technology, which is applied in the field of anti-mold treatment of flat glass, can solve the problems of affecting the appearance quality of glass and deep processing, difficult uniformity of film formation, and difficult cleaning of film formation, etc. Liquid splashing, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

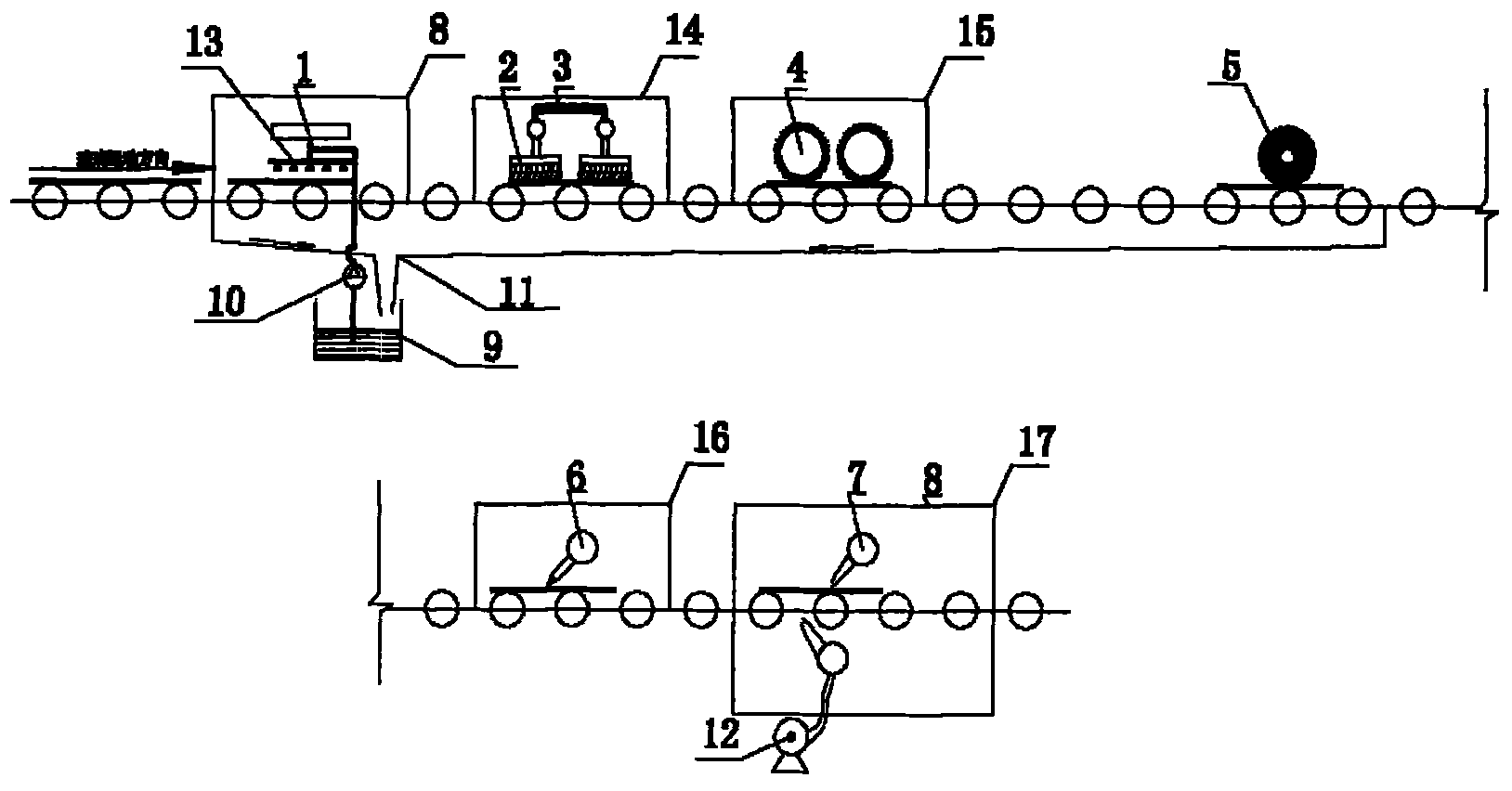

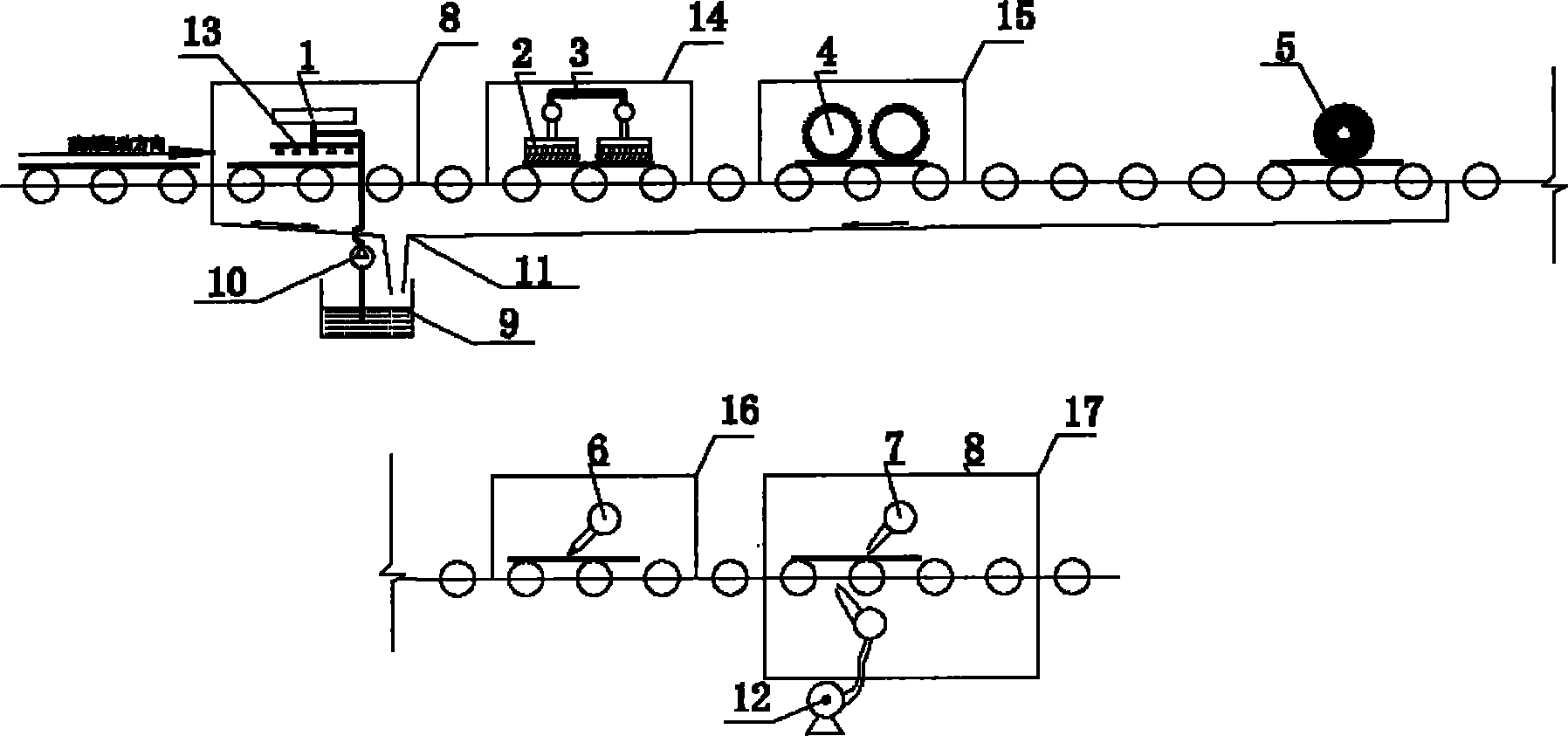

[0045] Taking the glass melting volume of 200t / d, the original glass plate width of 4 meters, and the glass thickness of 5 mm as an example, the rear running speed of the glass production line is about 166.67 meters per hour. Mildew treatment, the operation steps are as follows:

[0046] 1) On the flat glass production line, install an anti-mold liquid spraying machine from the edge-cut glass. The outlet pressure of the hydraulic pump is 0.25 MPa, and the pump output is 2 liters / min; Rare earth chloride salt; Hydroxycarboxylic acids select lactic acid 5% for use in this example, and rare earth chloride salt selects cerium chloride 1% for use, and all the other are water;

[0047] 2) The distance between the anti-mold liquid spraying machine, the disk brush and the roller brush is 20 cm each; the flat glass sprayed with the anti-mold liquid has been successively washed by two disk brushes and two roller brushes to make the surface of the flat glass Completely soak in a thin la...

example 2

[0054] Taking the glass melting capacity of 800t / d, the original glass plate width of 5.2 meters, and the glass thickness of 5 mm, the rear running speed of the glass production line is about 513 meters per hour. Anti-mildew treatment is carried out on the surface of the cut and edged flat glass. The operation steps are basically the same as in Example 1, the difference lies in:

[0055] 1) The outlet pressure of the hydraulic pump in the anti-mold liquid spraying machine is 0.28 MPa, and the pump output is 8 liters / minute; the anti-mold liquid is selected from hydrochloric acid;

[0056] 2) The distance between the anti-mold liquid spraying machine, two disc brushes and two roller brushes is 25 cm each; the flat glass completely soaked in the anti-mold liquid, after standing for 2 to 10 minutes, the anti-mold liquid and the glass surface are fully Contact, and make the K, Na and other alkali metal ions in the upper and lower surfaces of the glass and the rare earth ions in th...

example 3

[0061] Taking the glass melting capacity of 1000t / d, the original glass plate width of 4 meters, and the glass thickness of 5 mm as an example, the downstream running speed of the glass production line is about 833.33 m / h. The operation steps are basically the same as in Example 1, the difference lies in:

[0062] 1) The outlet pressure of the hydraulic pump in the anti-mold liquid spraying machine is 0.30 MPa, and the pump output is 10 liters / minute; the anti-mold liquid used is composed of hydroxypropionic acid, hydrochloric acid, citric acid, chlorinated The mixture of cerium chloride and neodymium chloride in rare earth salt, the ratio of each component is: 10% of hydroxypropionic acid; 8% of hydrochloric acid; 6% of citric acid; 3% of cerium chloride; 4% of neodymium chloride %, the rest is water;

[0063]2) The anti-mold liquid spraying machine, the two disc brushes and the two roller brushes are each set at a distance of 30 cm, and are completely immersed in the anti-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com