Ultrathin flexible cover plate and preparation method thereof

A flexible cover, ultra-thin technology, applied in branch office equipment, telephone structure, telephone communication, etc., can solve problems such as easy crushing and sputtering, human hazards, and the bending performance and strength of the cover plate cannot meet the use requirements at the same time, to achieve Effects of improving bending performance and strength and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

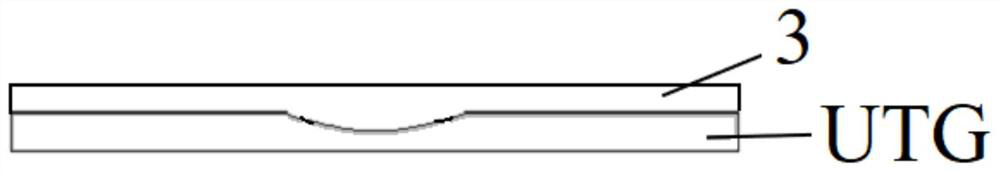

[0039] For the ultra-thin flexible cover with the above structure, this embodiment provides a method for preparing an ultra-thin flexible cover, including the following steps:

[0040] S1. Fix the UTG on the base;

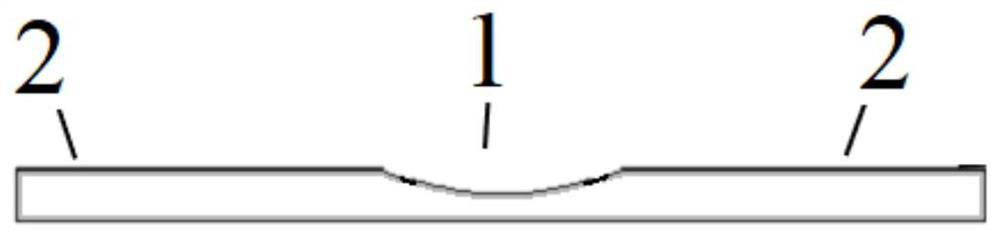

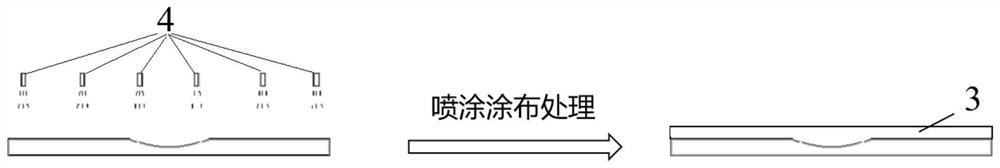

[0041] S2. The coating method of spraying treatment is used for processing. Multiple rows of nozzles 4 are arranged directly above the UTG. All nozzles 4 in the same row are arranged at equal intervals. All nozzles 4 in the same row are in the width direction of the UTG (that is, not equal Thick zone 1 and the width direction of equal thickness zone 2) are parallel on the same straight line.

[0042] In the above step S2, the thickness of the equal thickness area 2 is 100um, the minimum thickness of the non-equal thickness area 1 is 60um, and the maximum thickness of the non-equal thickness area 1 is 100um. After coating, the equal thickness area 2 and the non-equal thickness area are required The total thickness of 1 is 120um. During processing, the amount of so...

Embodiment 2

[0044] For the ultra-thin flexible cover with the above structure, this embodiment provides a method for preparing an ultra-thin flexible cover, including the following steps:

[0045] S1. Fix the UTG on the base;

[0046]S2. The coating method of spraying treatment is used for processing. Multiple rows of nozzles 4 are arranged directly above the UTG. All nozzles 4 in the same row are arranged at unequal intervals. All nozzles 4 in the same row are in the width direction of the UTG (that is, not On the same straight line parallel to the width direction of the constant thickness zone 1 and the constant thickness zone 2 , the number of nozzles 4 located above the constant thickness zone 2 is less than the number of nozzles 4 located above the non-equal thickness zone 1 .

[0047] In the above step S2, the thickness of the equal thickness area 2 is 100um, the minimum thickness of the non-equal thickness area 1 is 80um, and the maximum thickness of the non-equal thickness area 1 ...

Embodiment 3

[0049] For the ultra-thin flexible cover with the above structure, this embodiment provides a method for preparing an ultra-thin flexible cover, including the following steps:

[0050] S1, place the UTG on the conveyor belt 5;

[0051] S2. Processing by spraying coating method, a nozzle 4 is arranged directly above the conveyor belt 5, and the solution is sprayed from the nozzle 4 to the UTG. When the zone 1 moves to the bottom of the nozzle 4, the running speed of the conveyor belt 5 is different, so as to achieve different spraying effects.

[0052] In the above step S2, the thickness of the equal thickness area 2 is 100um, the minimum thickness of the non-equal thickness area 1 is 40um, and the maximum thickness of the non-equal thickness area 1 is 100um. After coating, the equal thickness area 2 and the non-equal thickness area are required The total thickness of 1 is 120um. During processing, the conveyor belt 5 transports the UTG to move linearly under the nozzle 4, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com