Low-viscosity 3D (three-dimensional) printing photo-curing material

A light-curing material and 3D printing technology, applied in the field of 3D printing, can solve the problems of high cost and high relative viscosity, and achieve the effects of cost reduction, small volume shrinkage, and good comprehensive mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

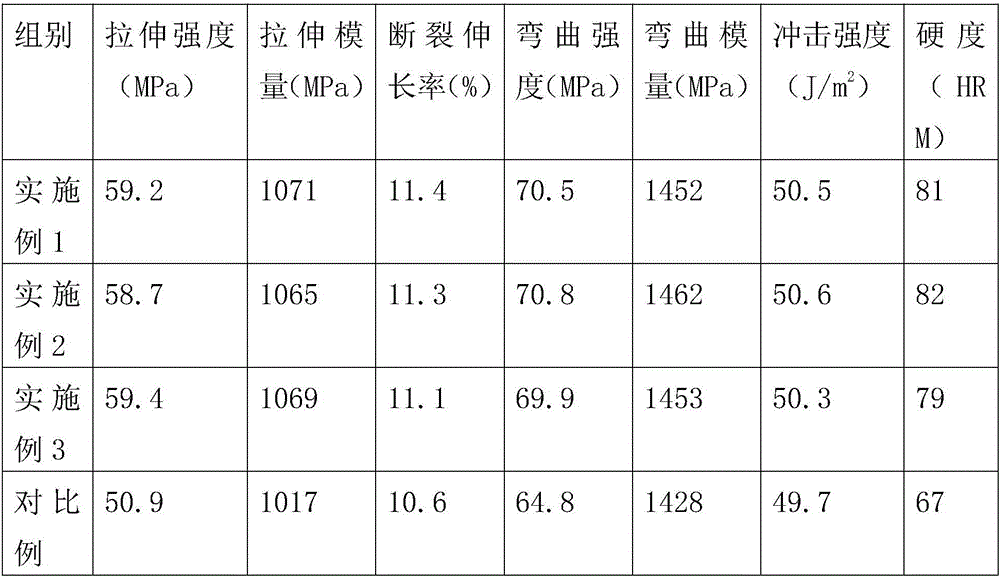

Examples

Embodiment 1

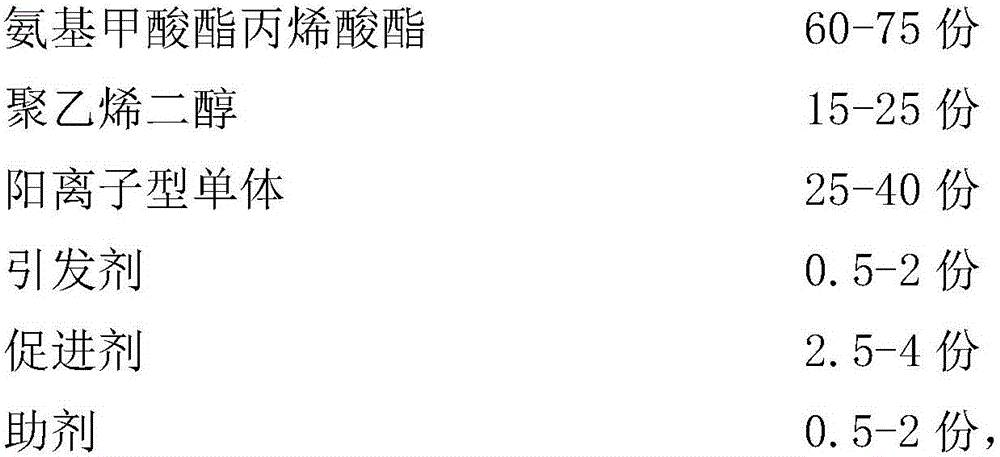

[0022] A 3D printing light-curing material is disclosed in Example 1, and the material formulation in Example 1 is shown in Table 1.

[0023] Formulation table in the embodiment 1 of table 1

[0024] components

Embodiment 2

[0026] A 3D printing light-curing material is disclosed in Example 2, and the material formulation in Example 2 is shown in Table 2.

[0027] Formulation table in table 2 embodiment 2

[0028] components

Embodiment 3

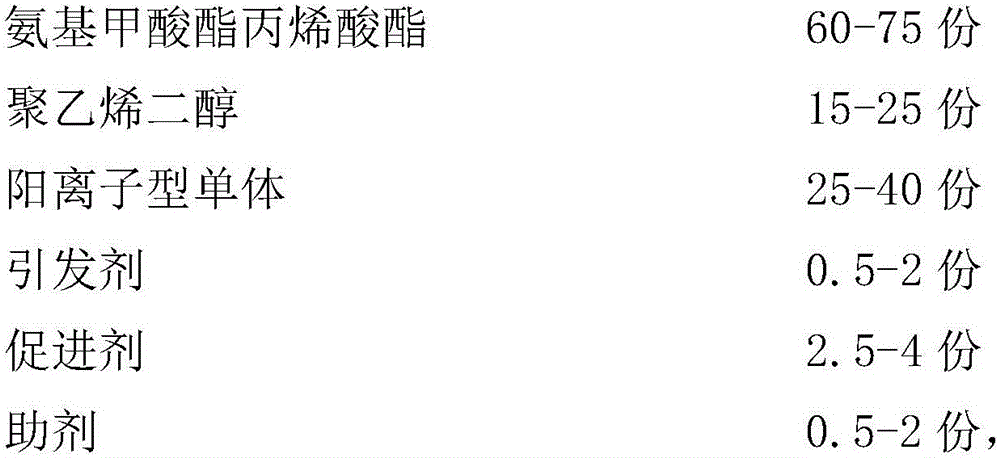

[0030] A 3D printing photocurable material is disclosed in Example 3, and its formulation is shown in Table 3.

[0031] Formulation table in the embodiment 3 of table 3

[0032] components

content

urethane acrylate

75

polyethylene glycol

25

40

1-Hydroxycyclohexylbenzophenone

2

4

Auxiliary

2

[0033] Other embodiments are also designed, and oxetane is selected as the cationic monomer. It is verified by experiments that alicyclic epoxy and oxetane are respectively coordinated with benzyl alcohol, and their effects in the entire material formula are not much different. .

[0034] Among them, the above-mentioned urethane acrylate has a density of 1.09g / cm at 25°C 3 , the viscosity is 150-175mPs.s, during the 3D printing process, the working temperature of the nozzle is 50-55°C, and the surface tension is 39.5-39.1mN / m; when preparing the material, add the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| cure shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com