Center alignment device in carbon film resistor printing process

A carbon film resistor and process technology, applied in the direction of containing printed resistors, containing printed electrical components, printed circuits, etc., can solve the problems of time and effort, trouble, waste of carbon ink, etc., to save use, easy to use. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

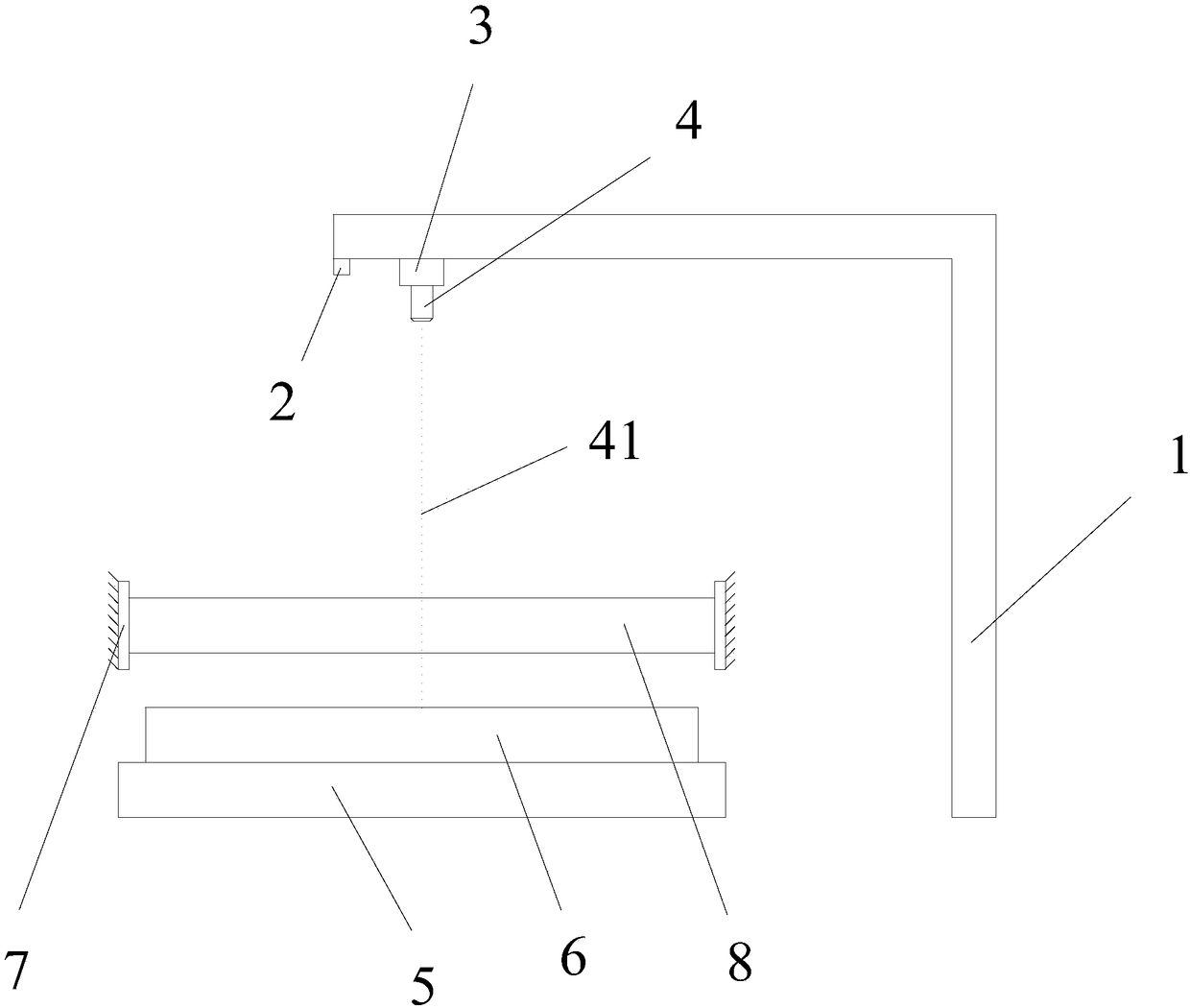

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0017] The fifth step of alignment adjustment mentioned above in the background art requires that the graphic area on the screen 8 be aligned with the carbon ink graphic to be printed on the ceramic substrate 6 . Because when the center of the graphics area on the screen 8 is aligned with the center of the carbon ink graphics to be printed on the ceramic substrate 6, the graphics area on the screen 8 and the carbon ink graphics to be printed on the ceramic substrate 6 are also aligned naturally , so the idea of the present invention is to set a method to quickly align the center of the graphic area on the screen 8 with the center of the carbon ink graphic to be printed on the ceramic substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com