Silicone resin composition and sealing material for semiconductor light emitting element

A technology of resin composition and silicone, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., and can solve the problems of low UV light extraction efficiency, poor refractive index, and large refractive index difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

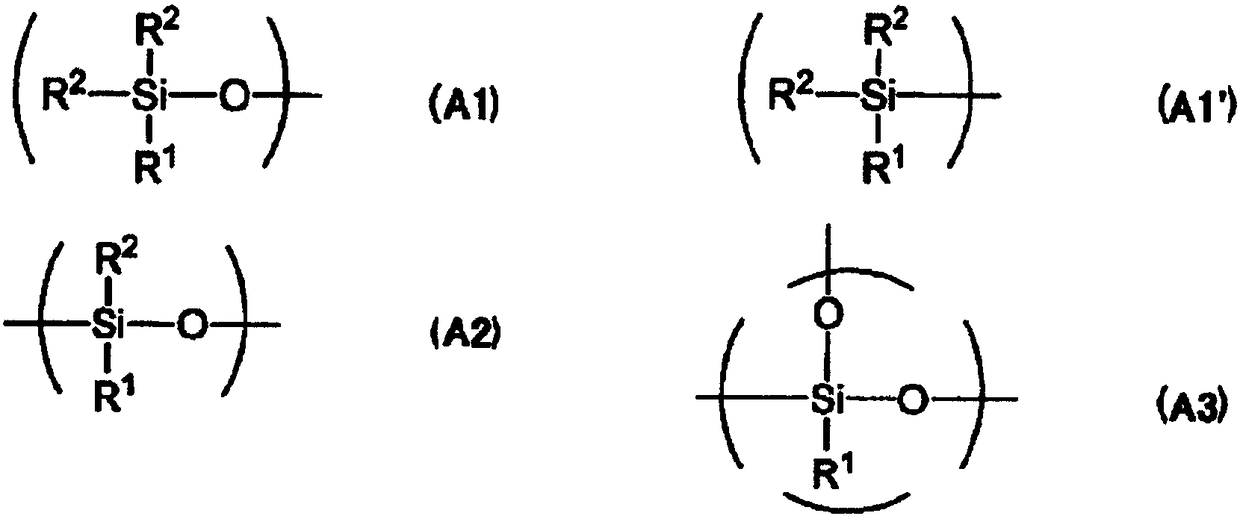

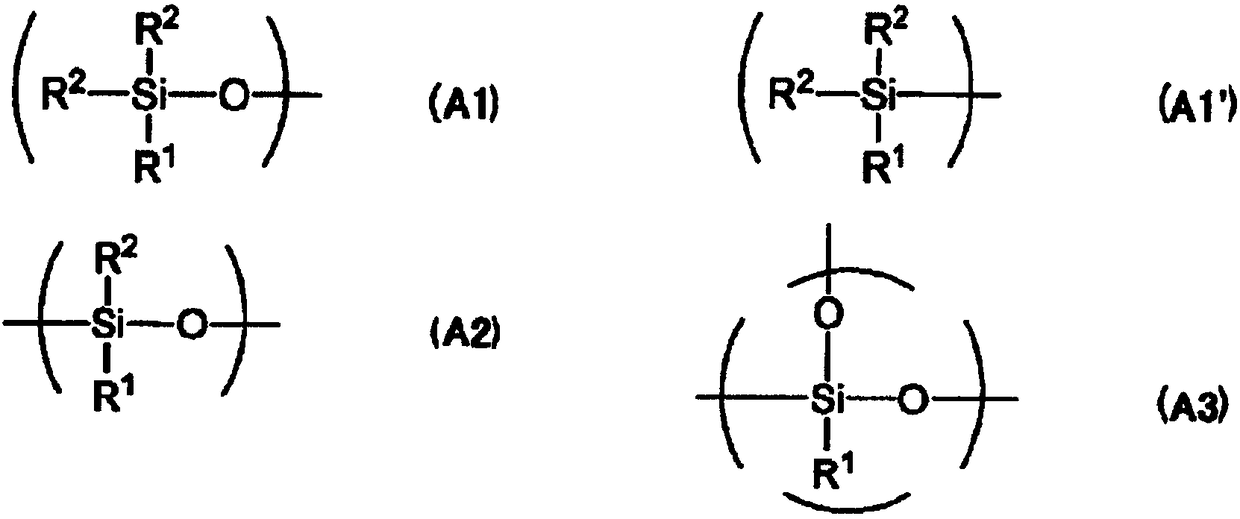

Method used

Image

Examples

Embodiment 1

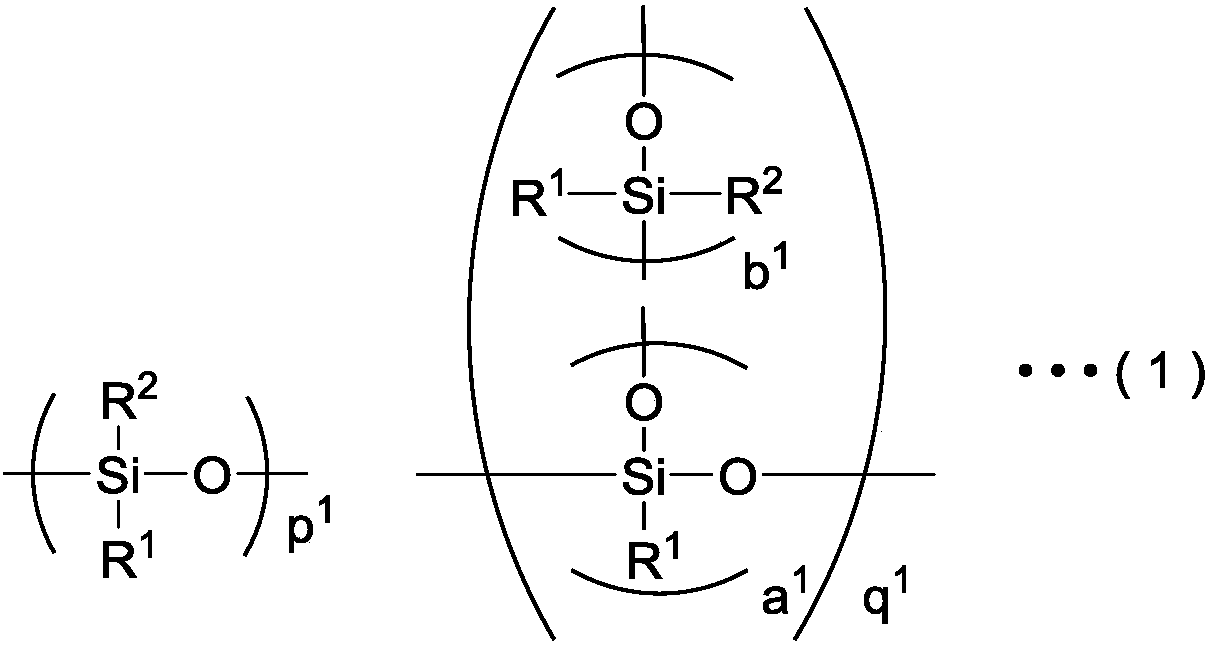

[0227] As the first silicone resin, a silicone resin 1 having an organopolysiloxane structure represented by the above formula (1) (Mw=3500, in the above formula (1), R 1 = Methyl, R 2 = methoxy or hydroxyl). Table 1 shows the abundance ratio of each structural unit of the silicone resin 1.

[0228] [Table 1]

[0229]

[0230] When the silicone resin 1 was heated from room temperature to 200° C. at a temperature increase rate of 5° C. / min and held in air at 200° C. for 5 hours, the mass loss rate was 10.3%.

[0231] As the second silicone resin, MSP-S110 (manufactured by NIKKO RICA CORPORATION) was used. The mass loss rate when MSP-S110 was heated from room temperature to 200°C at a temperature increase rate of 5°C / min and kept in air at 200°C for 5 hours was 3.5%. Table 2 shows the abundance ratio of each structural unit of MSP-S110.

[0232] [Table 2]

[0233]

[0234] 35.04 g of silicone resin 1, 23.36 g of MSP-S110 as the second silicone resin, and 21.60 g of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com