Conveying belt device

A conveyor belt and transmission mechanism technology, applied in the direction of lifting devices, hoisting devices, conveyor objects, etc., can solve the problems of not being able to meet the requirements of automatic pick-up by manipulators, failure of trolley limit warning, shortening the service life of trolleys, etc., to achieve stable transmission Good performance, faster production tempo, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

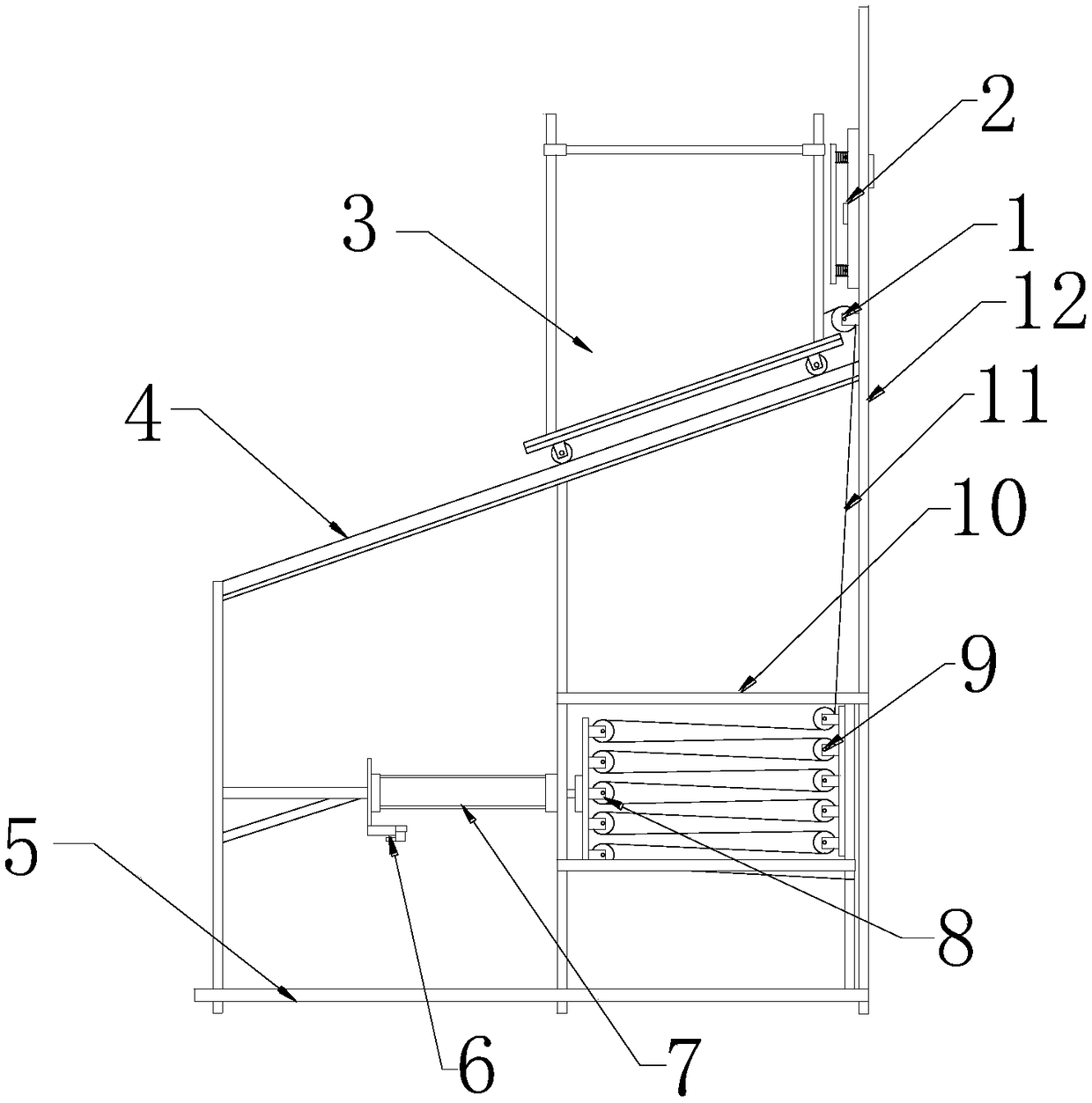

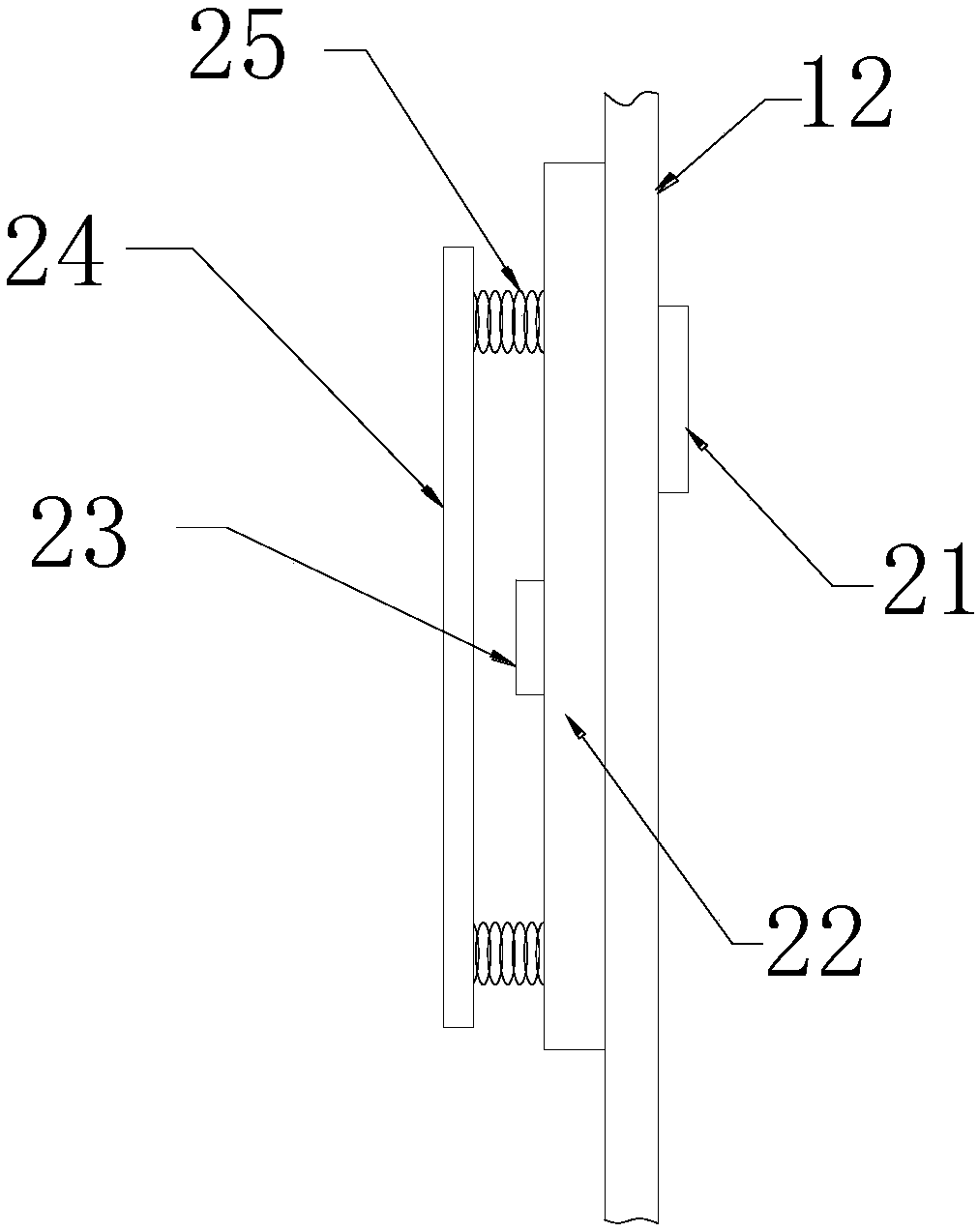

[0022] Specific implementation method: when in use, the mold is opened, and the working signal is output to the manipulator. The solenoid valve 6 obtains the signal of mold opening, and outputs it to the cylinder 7, and then the cylinder 7 contracts. The contraction of the cylinder 7 drives the moving pulley carrier to move to the left, and the moving pulley The movement of the carrier plate drives the movable pulley block 8 to move, and the movable pulley block 8 moves to stretch the steel wire rope 11, and then the steel wire rope 11 drives the fixed pulley block 9 and the upper fixed pulley 1 to rotate. 3. Move the top position of the carrier 4 to receive the product grabbed by the manipulator. When the product is placed on the trolley 3, the cylinder 7 is running, and the cylinder 7 is ejected, and then the movable pulley carrier plate drives the movable pulley block 8 to move to the right, thereby relaxing the wire rope 11 , under the gravity of the trolley 3 itself, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com