Reuse equipment and method for wickerwork printing and dyeing wastewater treatment

A technology for printing and dyeing wastewater and willow weaving, which is applied in processing wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The wastewater quality of the willow printing and dyeing workshop of a willow handicraft company is: COD: 3240~4150mg / L; light transmittance: 0.01%~0.02%; SS: 1130.3~1330.7mg / L.

[0048] Apply the willow printing and dyeing wastewater treatment and reuse method of the present invention, comprising the following steps:

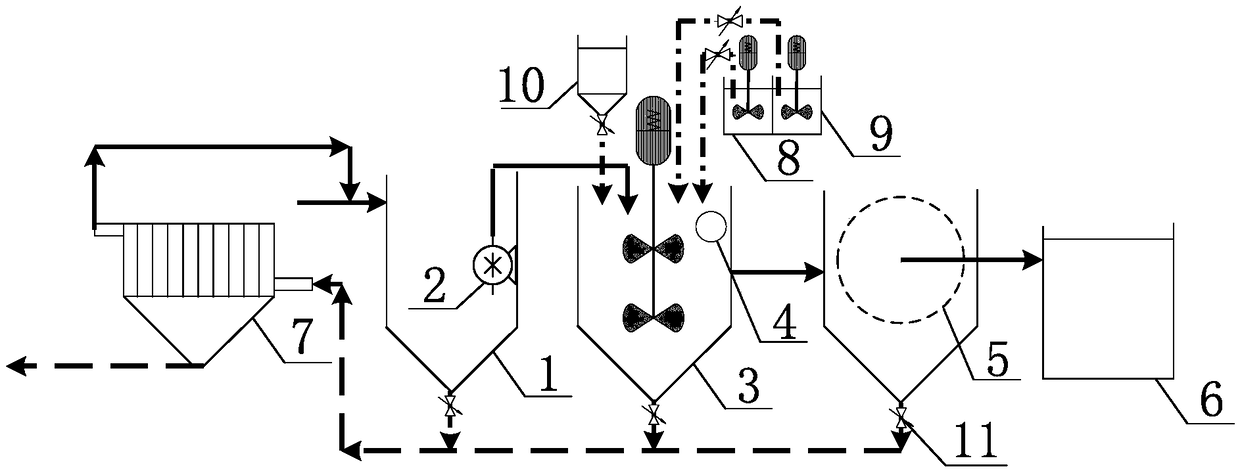

[0049] (1) The waste water produced in the willow printing and dyeing process flows into the waste water pool 1, and the impurities with a larger proportion in the waste water settle to the bottom of the pool;

[0050] (2) A lift pump 2 is installed in the waste water tank, and the waste water enters the coagulation sedimentation tank 3 after being lifted by the lift pump 2. The flocs with large size and specific gravity are formed through the process of flocculant complexation, net capture and sweeping, and settle to the bottom of the tank by gravity during the sedimentation process;

[0051]The coagulant and coagulant aid are ferrous sulfate, calcium ...

Embodiment 2

[0061] The wastewater quality of the willow printing and dyeing workshop of a willow handicraft company is: COD: 3350-4010mg / L; light transmittance:

[0062] 0.01%~0.03%; SS: 1020.3~1130.7mg / L.

[0063] Apply the willow printing and dyeing wastewater treatment and reuse method of the present invention, comprising the following steps:

[0064] (1) The waste water produced in the willow printing and dyeing process flows into the waste water pool 1, and the debris with a larger proportion in the waste water settles to the bottom of the pool;

[0065] (2) A lift pump 2 is installed in the waste water tank, and the waste water enters the coagulation sedimentation tank 3 after being lifted by the lift pump 2. The flocs with large size and specific gravity are formed through the process of flocculant complexation, net capture and sweeping, and settle to the bottom of the tank by gravity during the sedimentation process;

[0066] The coagulant and coagulant aid are ferrous sulfate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average removal rate | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com