Conical sound horn focusing coupled intrinsic interference type fiber grating ultrasonic sensor

A technology of ultrasonic sensor and optical fiber grating, which is applied in the field of sensors to achieve good response characteristics and improve the effect of signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

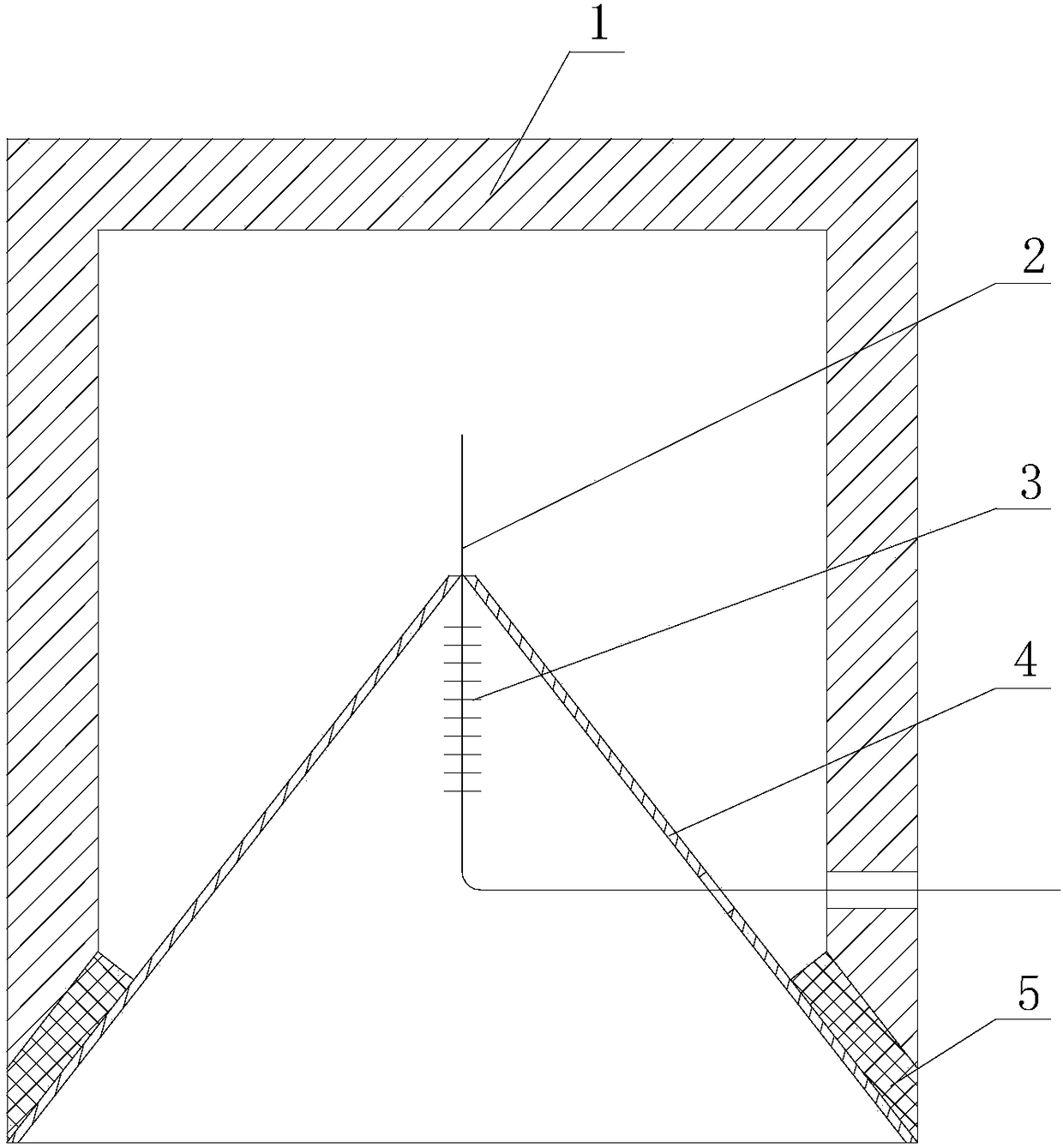

[0020] In this embodiment, one end of the housing 1 is closed, and the other end is equipped with an acoustic coupling cone 4. The diameter of the bottom surface of the acoustic coupling cone 4 is the same as the outer diameter of the housing 1, and the cone angle of the acoustic coupling cone 4 is 60°. Other components And the connection relation of parts is identical with embodiment 1.

Embodiment 3

[0022] In this embodiment, one end of the housing 1 is closed, and the other end is equipped with an acoustic coupling cone 4. The diameter of the bottom surface of the acoustic coupling cone 4 is the same as the outer diameter of the housing 1, and the cone angle of the acoustic coupling cone 4 is 120°. Other components And the connection relation of parts is identical with embodiment 1.

Embodiment 4

[0024] In the above embodiments 1-3, one end of the housing 1 is closed, and the other end is equipped with an acoustic coupling cone 4, the diameter of the bottom surface of the acoustic coupling cone 4 is the same as the outer diameter of the housing 1, and the diameter of the bottom surface of the acoustic coupling cone 4 is 1mm. The cone angle of the coupling cone 4 is the same as that of the corresponding embodiment, and the other components and their connection relations are the same as those of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com