Large-capacity heat-not-burn tobacco product simulated experimental analysis apparatus and method

A heat-not-burn, tobacco product technology, applied in the field of tobacco analysis, can solve the problems of uneven heating of tobacco products, accuracy of temperature measurement, unclear heating uniformity of cut tobacco, unstable heating temperature, etc. The effect of secondary cracking and high sample capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] The present invention will be further described in detail below in conjunction with the drawings.

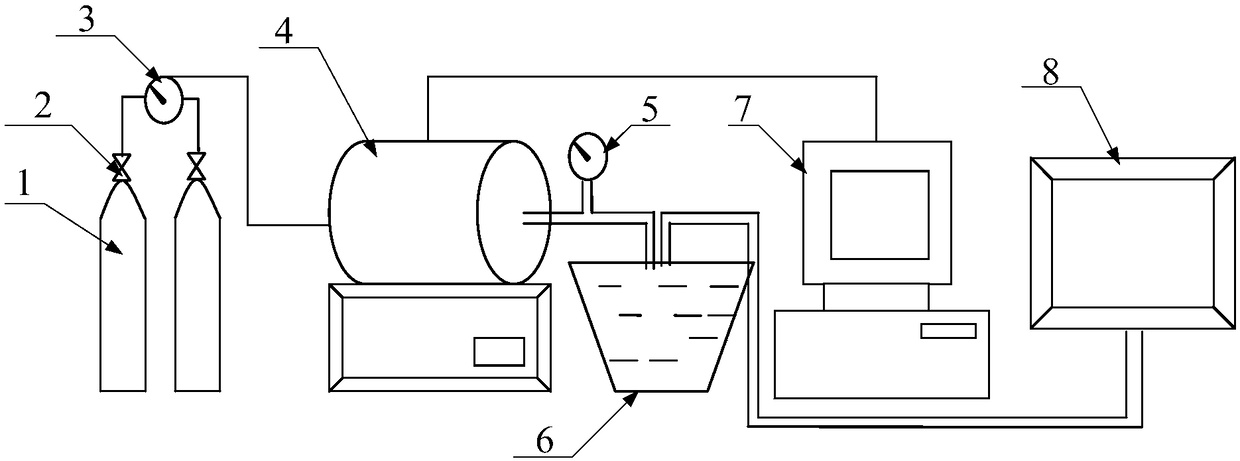

[0031] See figure 1 , The present invention includes two gas cylinders 1, which are equipped with gas sources required for the experiment; each gas cylinder 1 is provided with a gas source pressure reducing valve 2, and the two gas source pressure reducing valves 2 are simultaneously connected to the gas flow controller 3. ; The gas flow controller 3 is connected to the tubular heating furnace 4, the gas flow meter 5, the gas collection device 6 and the chromatographic mass spectrometer 8 in sequence.

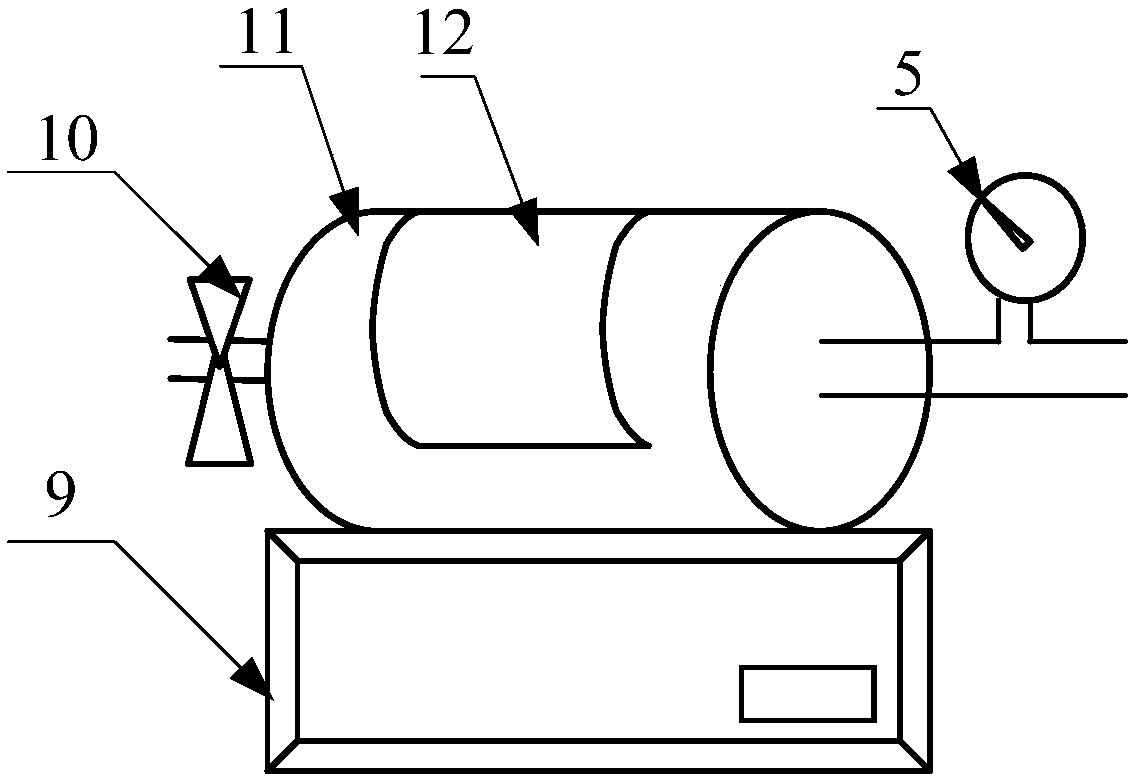

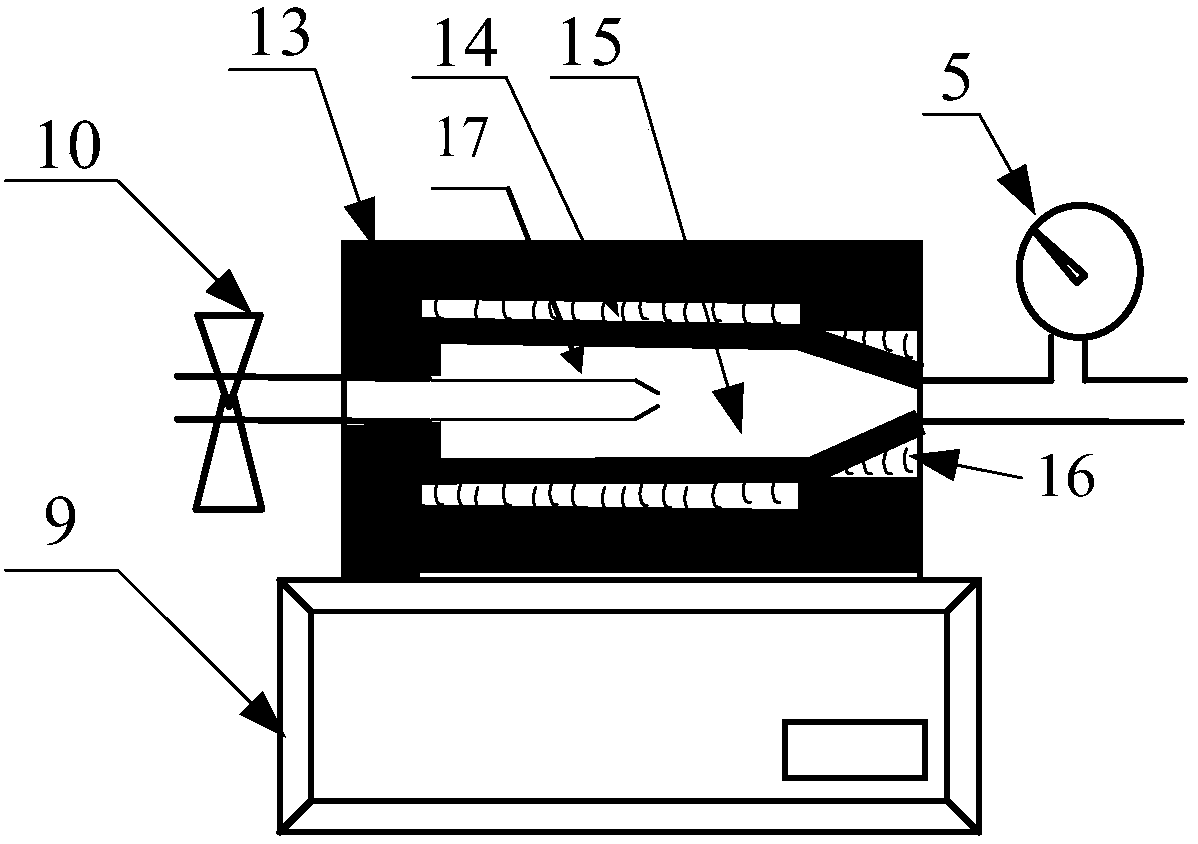

[0032] See figure 2 with image 3 The tube heating furnace 4 includes a furnace body 11 and an inner tube 15 arranged inside the furnace body 11. A furnace mouth for taking out the inner tube 5 is opened on the side wall of the furnace body 11, and a furnace cover 12 is provided at the furnace mouth for easy removal The inner tube 15 is filled with tobacco samples; a heating ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap