Combined wind-driven grain cleaning machine and combined wind-driven grain cleaning method thereof

A combined, grain-clearing technology, applied in chemical instruments and methods, solid separation, and separation of solids from solids by air flow, etc., can solve the problems of low separation rate of grain and dust, grass and leaves, and high loss rate of grains. Achieve the effect of solving low separation rate, low cost and improving contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

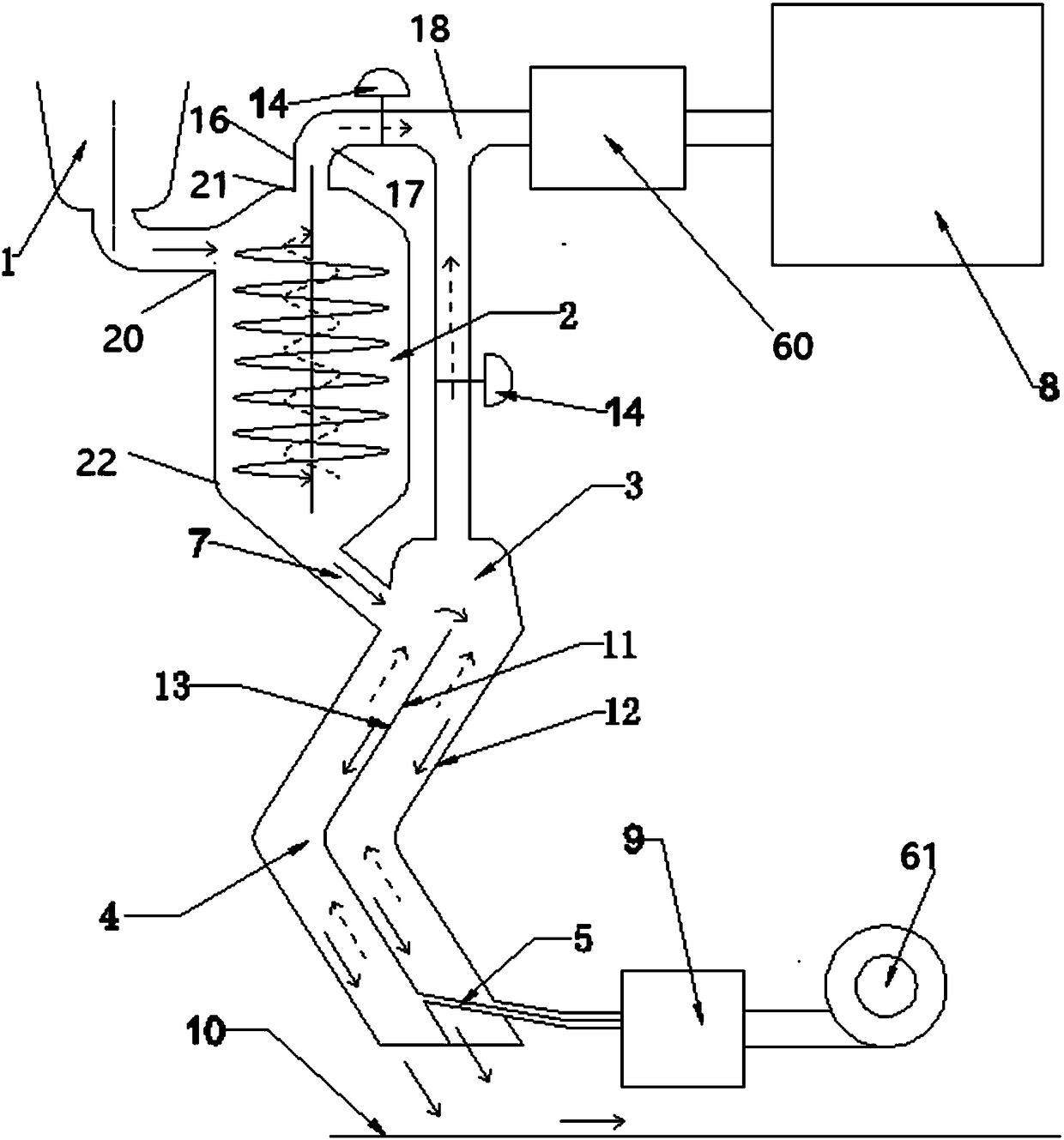

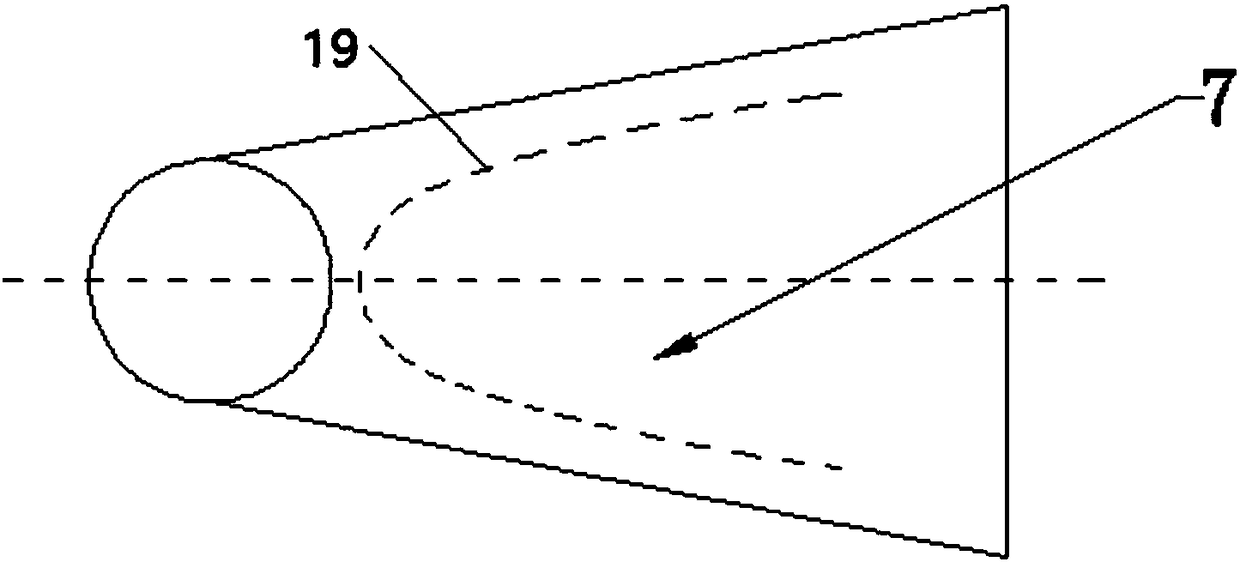

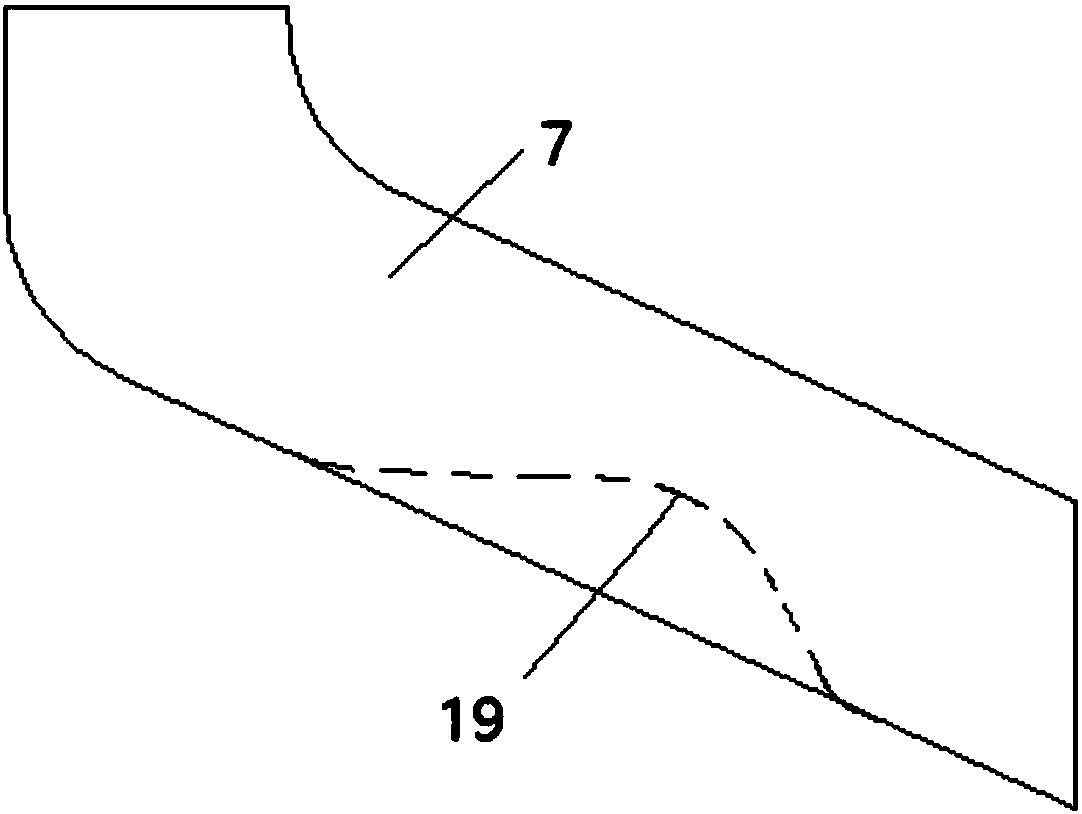

[0029] see figure 1 , the combined wind-powered grain cleaning machine of the present invention mainly includes a hopper 1, a cyclone separator 2, a dust collector 3, an inclined tube grain cleaning machine 4, a high-pressure blower one 60, a high-pressure blower two 61, a round mouth to a square mouth to disperse grain Structure 7, bag dust removal device 8, conveyor, air distributor 9.

[0030] The hopper 1 can adopt a common hopper structure, such as a trumpet-shaped structure, and the hopper 1 is mainly used for receiving materials. Materials in the present invention mainly refer to grains, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com