Chipping blowing device for machine tool workpieces

A workpiece and chip technology, applied in the field of machine tool processing auxiliary equipment, can solve problems such as adverse effects of mechanical structure movement, damage to parts and circuits, and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

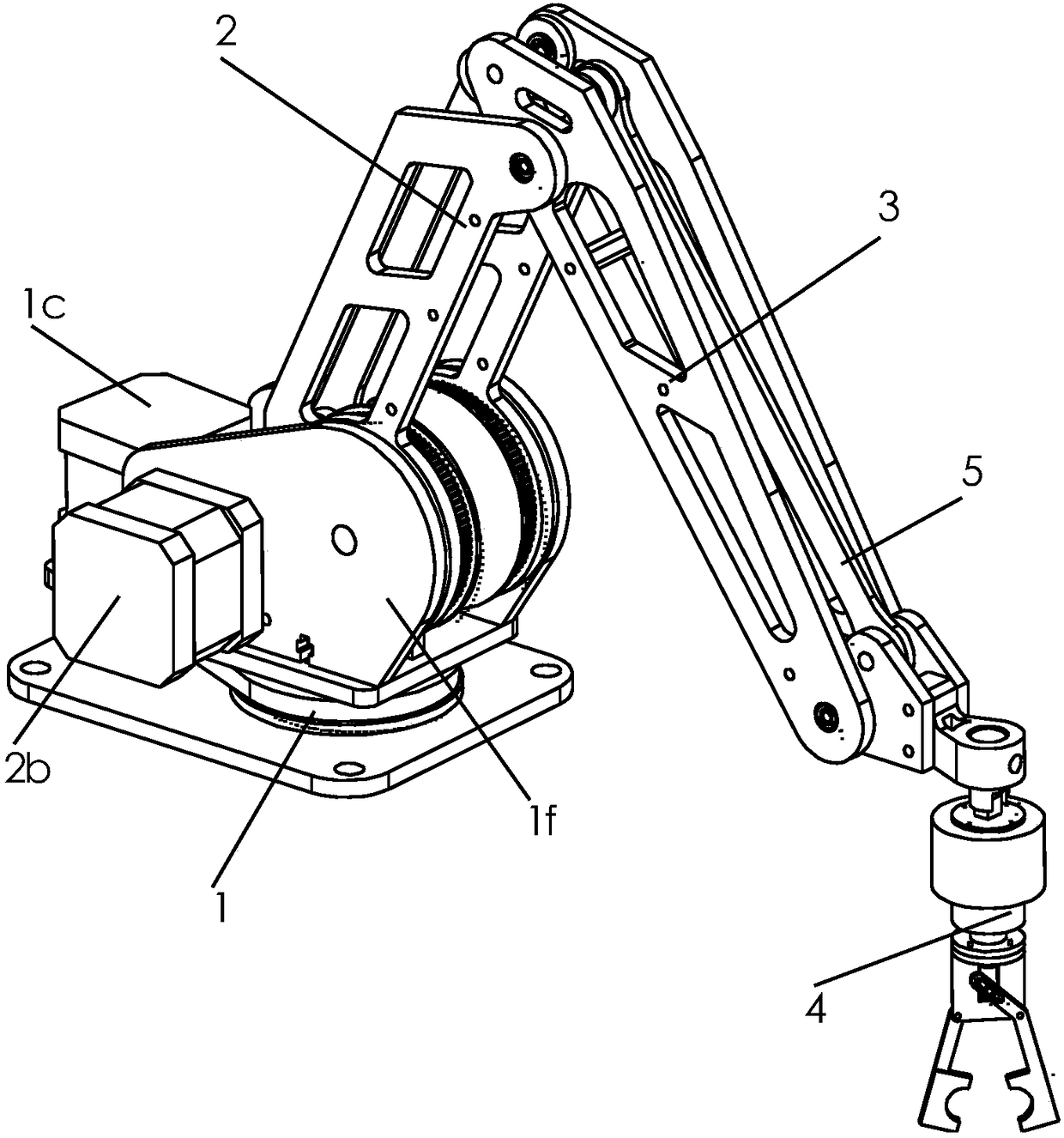

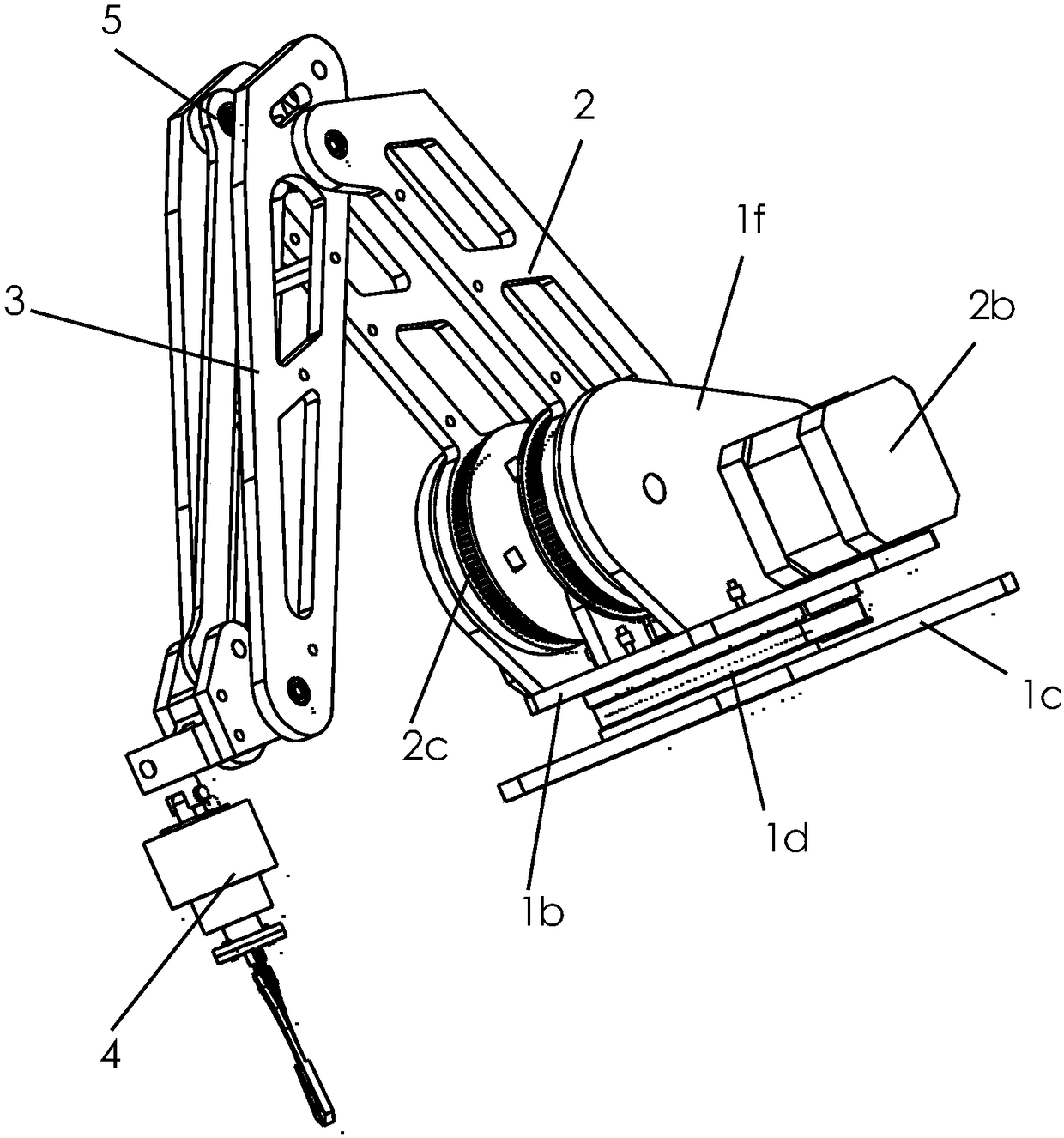

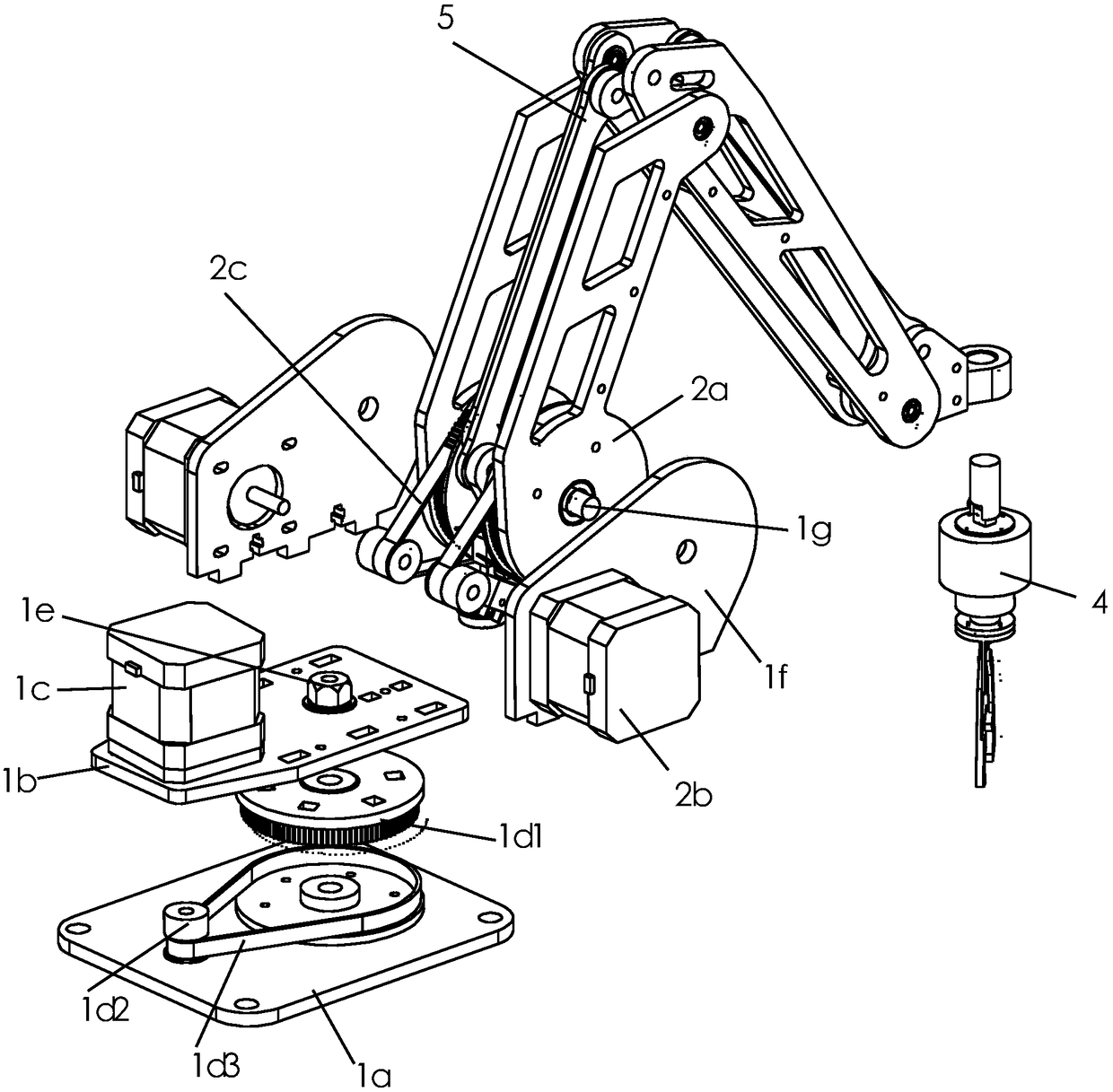

[0028] refer to Figure 1 to Figure 9 The shown device for blowing off debris from machine tool workpieces includes an air pump and an air pipe connected to the air pump, and also includes a rotating base 1 , a mechanical arm 2 , a mechanical arm 3 and a clamping claw 4 .

[0029] The rotating base 1 includes a lower support plate 1a and an upper support plate 1b arranged horizontally, the upper support plate 1b is rotatably arranged above the lower support plate 1a, and one end of the mechanical arm 2 is rotatably arranged on the upper support plate On the top of 1b, the end of the mechanical arm 2 away from the rotating base 1 is hinged to one end of the mechanical arm 3, the clamping claw 4 is rotatably arranged at the non-hinged end of the mechanical arm 3, and the top of the upper support plate 1b is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com