Camera bracket injection molding process and injection molding machine using the injection molding process

A camera and injection molding machine technology, applied in the field of injection molding, can solve the problems of increasing the production cost of plastic parts, different injection molding positions, waste of raw materials, etc., and achieve the effect of avoiding color difference, material waste, and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

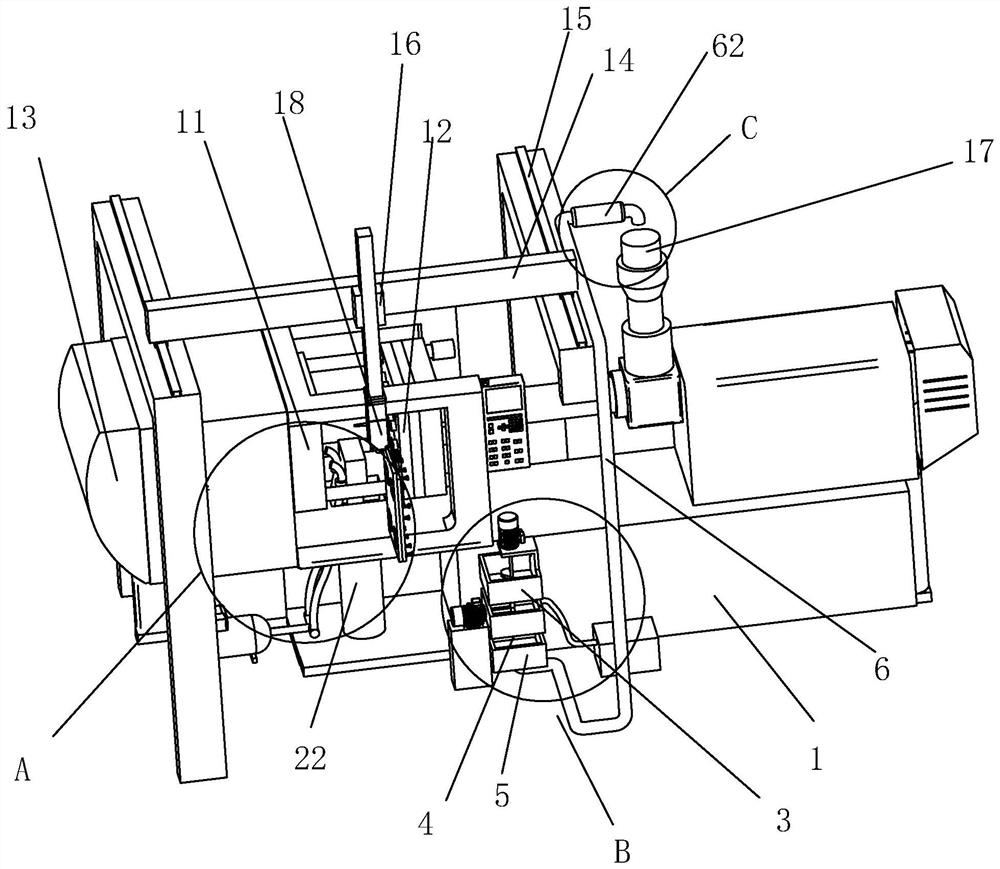

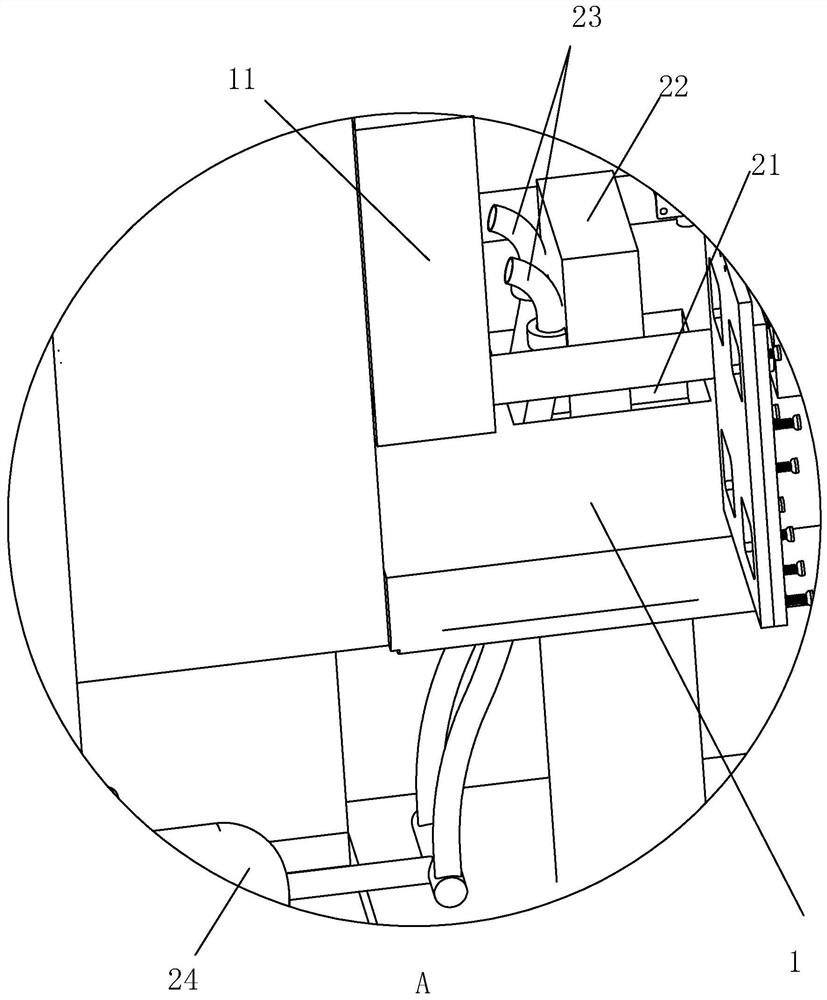

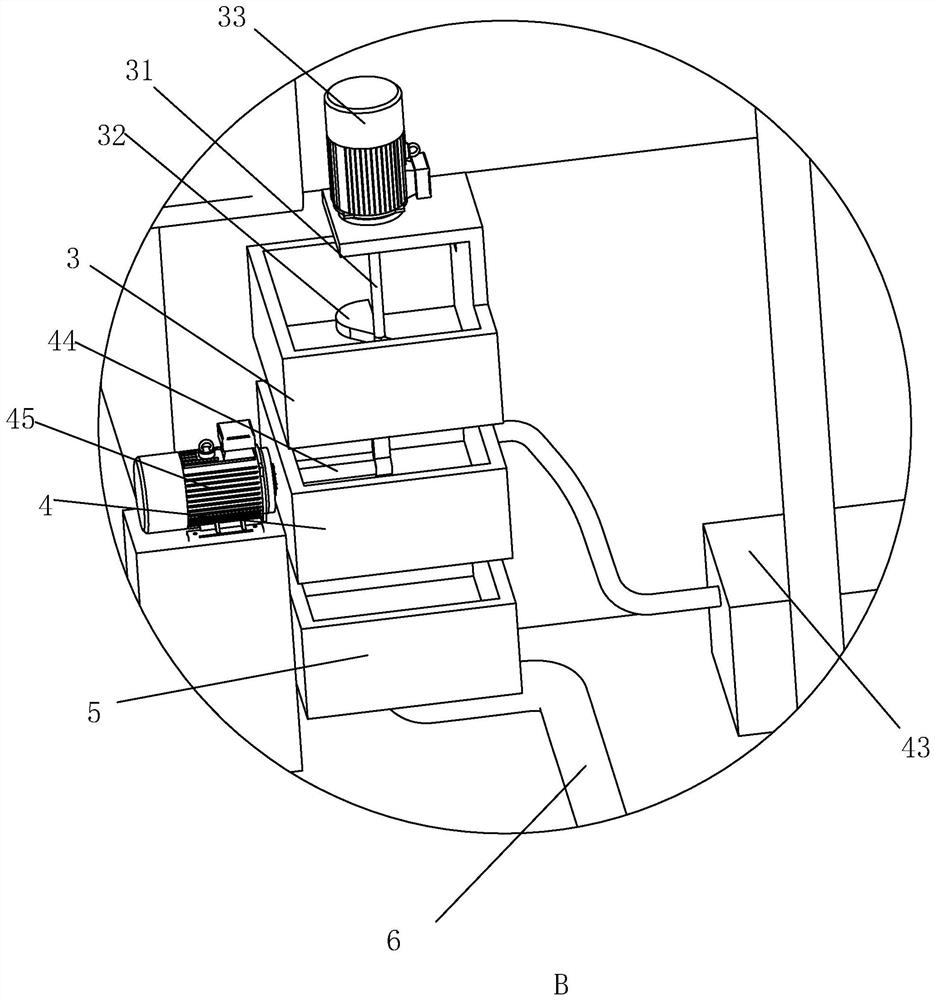

[0045] Embodiment 1: Embodiment 1: as figure 1 As shown, an injection molding machine includes a frame 1. The frame 1 is sequentially provided with a fixed mold 12 and a movable mold 11 along the length direction. The fixed mold 12 and the movable mold 11 are arranged oppositely. Screw, feeding hopper 17 is arranged above the feed screw, the first drive device 13 that drives the movable die 11 to move to the fixed die 12 is connected on the movable die 11, the first drive device 13 is an oil cylinder, and the piston rod of the oil cylinder and the movable die 11, so as to drive the movable mold 11 to move toward the fixed mold 12 or separate.

[0046] like figure 1 As shown, a second driving device 15 is arranged directly above the frame 1, the second driving device 15 is a rodless cylinder, a sliding block 14 is connected to the rodless cylinder, and a third driving device 16 is arranged on the sliding block 14. , the second driving device 15 is a cylinder, the piston rod o...

Embodiment 2

[0052] Embodiment 2: a kind of camera bracket injection molding process, comprises the following steps:

[0053] Step 1. Melt glue, put ABS plastic particles into the hopper of the injection molding machine, and at the same time, the injection molding machine heats the raw material to 260 degrees and extrudes it from the injection nozzle;

[0054] Step 2, closing the mold, merging the moving mold and the fixed mold;

[0055] Step 3: Injecting glue, injecting molten primary plastic particles into the mold;

[0056] Step 4, cooling, the cooling time is 1 second;

[0057] Step 5, open the mold, the mold opening time is 6 seconds;

[0058] Step 6, demoulding and blanking, the flow channel is clamped by the manipulator, and the camera bracket is sucked and blanked by negative pressure;

[0059] Step 7. Transport the runner to the shredding device by the manipulator;

[0060] Step 8: The chopped material forms recycled plastic particles, and then 0.5% cross-linking agent is adde...

Embodiment 3

[0062] Embodiment 3: a kind of camera bracket injection molding process, comprises the following steps:

[0063] Step 1. Melt glue, put PP plastic particles into the hopper of the injection molding machine, and at the same time, the injection molding machine heats the raw material to 250 degrees and extrudes it from the injection nozzle;

[0064] Step 2, closing the mold, merging the moving mold and the fixed mold;

[0065] Step 3: Injecting glue, injecting molten primary plastic particles into the mold;

[0066] Step 4, cooling, the cooling time is 2 seconds;

[0067] Step 5, open the mold, the mold opening time is 4 seconds;

[0068] Step 6, demoulding and blanking, the flow channel is clamped by the manipulator, and the camera bracket is sucked and blanked by negative pressure;

[0069] Step 7. Transport the runner to the shredding device by the manipulator;

[0070] Step 8: The chopped material forms recycled plastic particles, and then 1.5% cross-linking agent is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com