Climbing robot of electric power steel tube pole tower

A technology for electric steel pipes and robots, applied in the field of robots, can solve the problems of load-bearing and the inability of climbing robots to satisfy simple control at the same time, and achieve the effects of small impact, improved climbing speed, and increased attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

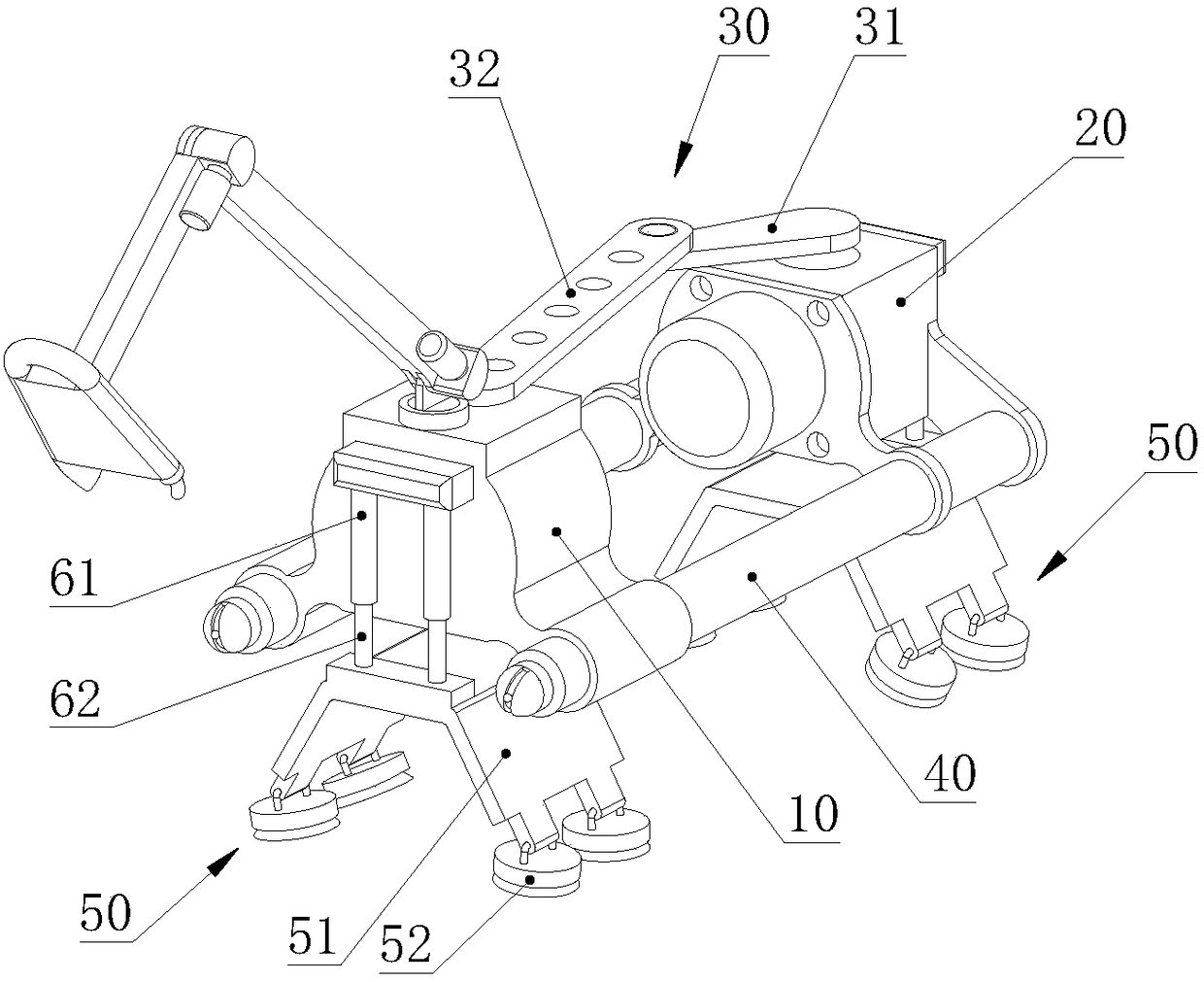

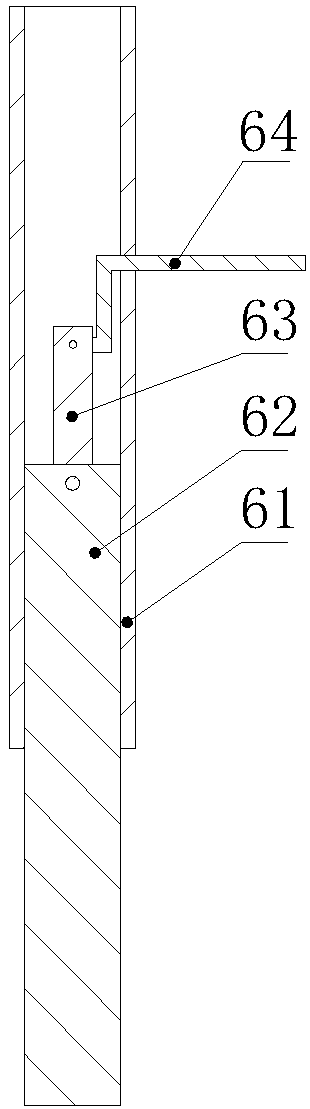

[0031] Please refer to figure 1 , an electric steel pipe pole tower climbing robot, comprising a front base 10 and a rear base 20 arranged at intervals one after the other, the tops of the two bases are connected together by a crankshaft linkage mechanism 30, and the crankshaft linkage mechanism 30 Crankshaft 31 is connected with the motor that is arranged on rear frame 20, and crankshaft 31 is done circular motion under the drive of motor, and the connecting rod 32 of crankshaft linkage mechanism 30 is movably connected with front frame 10.

[0032] The sides of the two machine bases are connected together by two parallel guide rods 40 , one end of the guide rods 40 is fixedly connected with the rear machine base 20 , and the other end of the guide rods 40 is slidably connected with the front machine base 10 . Driven by the crankshaft-link mechanism 30, the guide rod 40 and the front frame 10 can slide relatively. The direction of motion of the guide rod 40 is consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com