A method for improving the control ability of carbon at the end point of blowing steelmaking converter

A steel-making converter and control capability technology, which is applied to the improvement of process efficiency and the manufacture of converters, etc., can solve the problems of expensive auxiliary gun equipment, high probe consumption, low end-point hit rate, etc., and achieves the improvement of steel-making converter blowing End-point carbon control ability, improving blowing end-point carbon control ability, and the effect of avoiding uncertain factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A 120-ton top-bottom double-blown converter in a steelmaking plant is blown according to the method of the present invention, and the carbon content at the end point is required to be 0.10-0.18%. The specific conditions are shown in the following table.

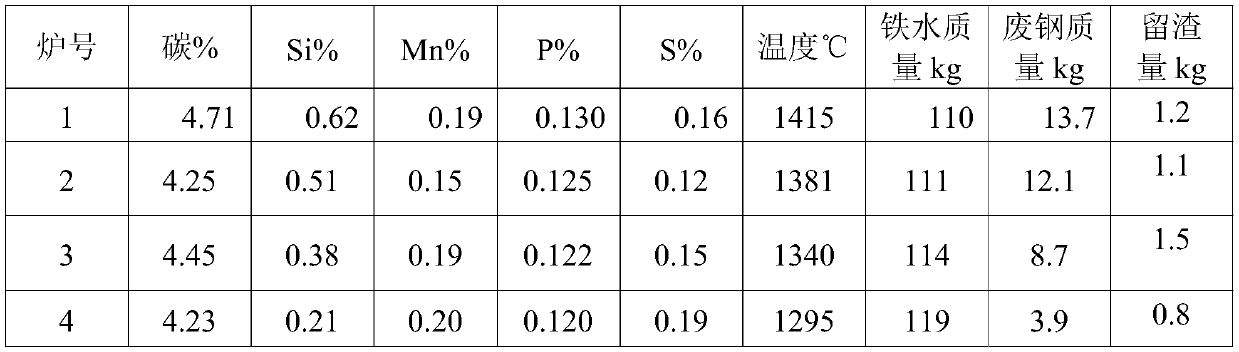

[0047] Table 1 shows the conditions of molten iron entering the furnace and the amount of steel scrap added:

[0048]

[0049]Table 2 is the first batch of charge additions:

[0050]

[0051]

[0052] Table 3 shows the slag composition and molten iron temperature at the end of the silicomanganese oxidation period:

[0053]

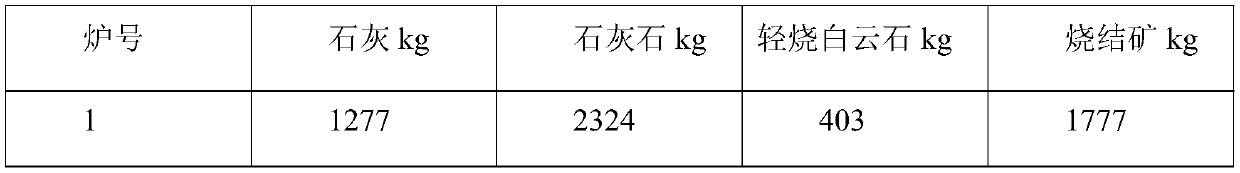

[0054] Table 4 is the second batch of charge addition:

[0055]

[0056] Table 5 is the final slag composition and end point carbon content:

[0057] furnace number MgO% TFe% Alkalinity End carbon % 1 9.1 15.6 3.02 0.15 2 9.2 16.5 2.90 0.12 3 8.5 17.1 3.31 0.11 4 9.5 18.6 3.38 0.10

Embodiment 2

[0059] A 100-ton top-bottom double-blown converter in a steelworks is blown according to the method of the present invention, and the carbon content at the end point is required to be 0.05-0.10%. The specific conditions are shown in the following table.

[0060] Table 1 shows the conditions of molten iron entering the furnace and the amount of steel scrap added:

[0061]

[0062]

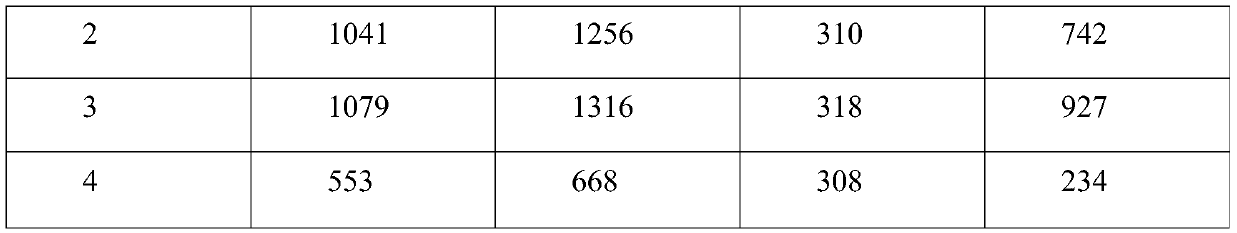

[0063] Table 2 is the first batch of charge additions:

[0064] furnace number Lime kg Limestone kg Light burnt dolomite kg Sinter kg 1 564 936 301 1121 2 654 890 321 932 3 701 2012 356 1217 4 899 2354 344 1129

[0065] Table 3 shows the slag composition and molten iron temperature at the end of the silicomanganese oxidation period:

[0066] furnace number MgO% TFe% Alkalinity Hot metal temperature ℃ 1 5.8 17.6 1.62 1416 2 6.2 18.1 1.41 1406 3 7.1 21.5 1.77 1394 4 5.2 18.0 1.46 1389

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com