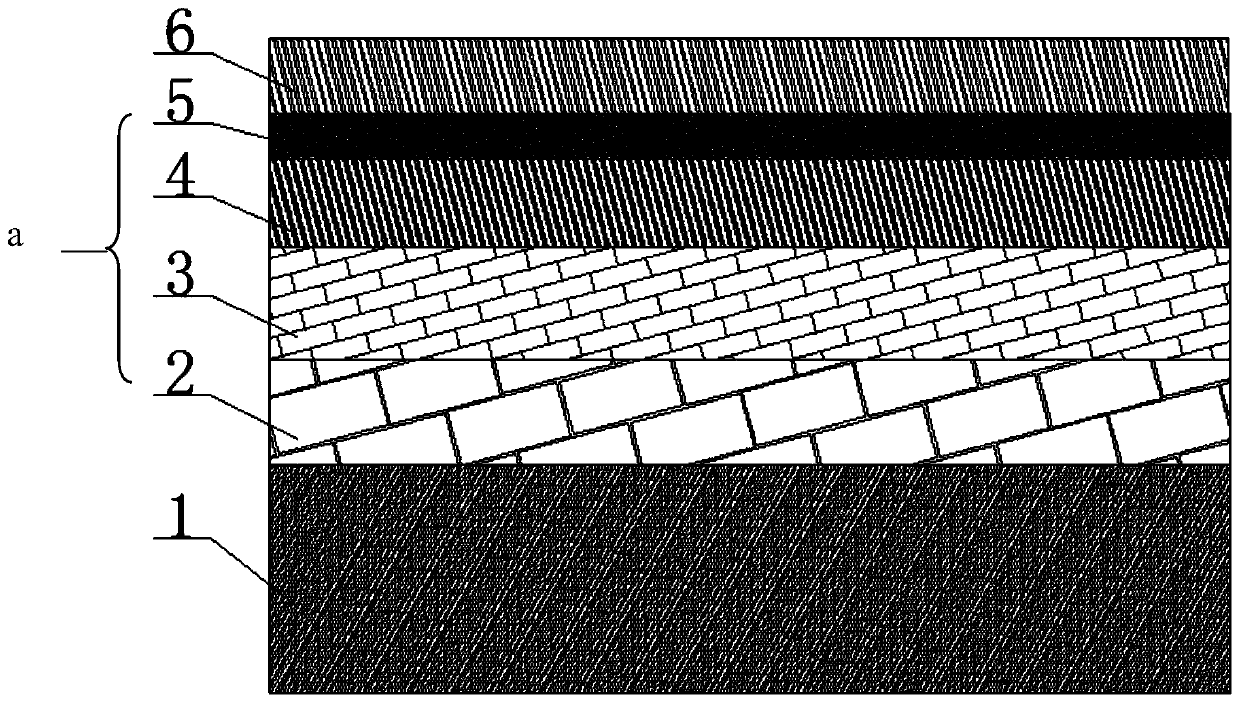

A method for preparing a hydrogen-free metal-doped diamond-like coating and its products

A diamond coating, metal doping technology, applied in metal material coating process, coating, vacuum evaporation plating and other directions, can solve the problems of arc spot etching, low target utilization rate, low deposition rate, etc. The effect of reducing the internal stress of the coating, improving the coating quality and fast deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

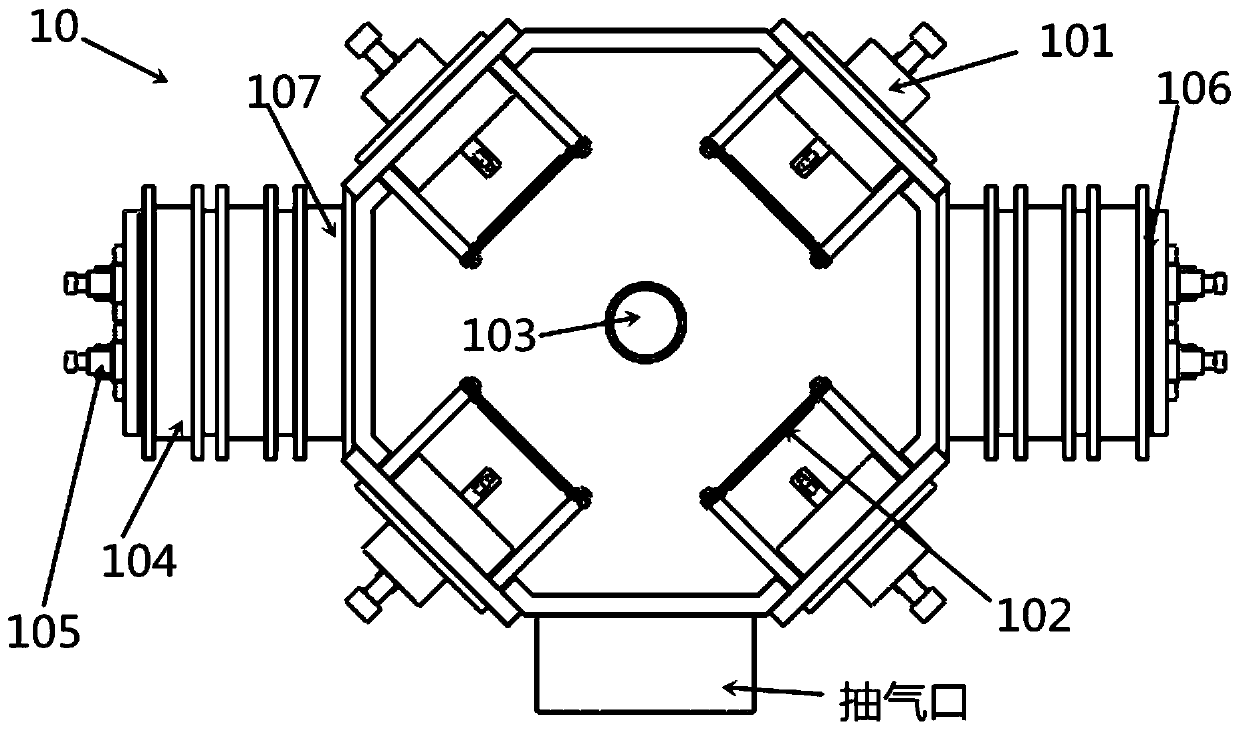

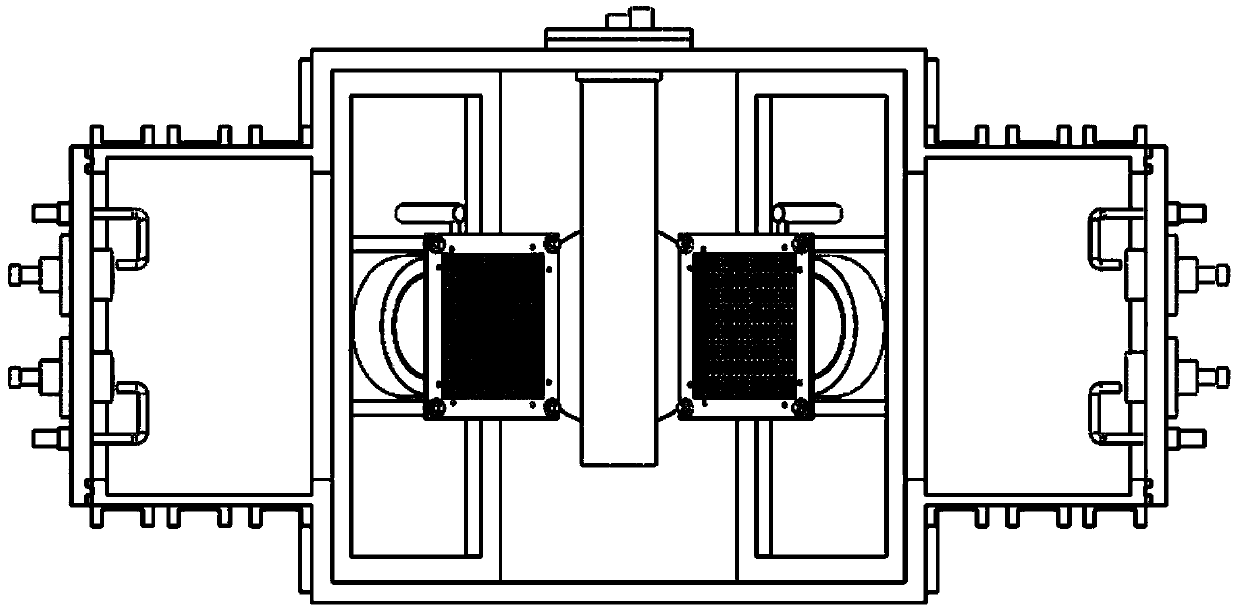

[0041] Note 1: Due to drawing needs, the gauze schematic diagram presented is an effect diagram, and the mesh number in actual application is generally 50-200 mesh, which is not the effect shown in the schematic diagram. The presented high-energy magnetic field coil does not exhibit the characteristics of a coil. In practical applications, the coil is evenly wound on the coil former.

[0042] Explanation 2: In this embodiment, the carbon particle source of carbonitride and carbide is a graphite target. During the preparation of carbonitride and carbide, the water-cooled anode is connected to facilitate further ionization of carbon particles; In the diamond coating, the carbon source is the carbon particles from the arc discharge of a small graphite target filtered by a high-energy magnet. When depositing the diamond-like coating, the metal arc source will undergo a gradient change process of 20 minutes, in order to form a metal-doped diamond-like coating. , thereby improving t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com