Dyeable polypropylene modified fibers

A technology of modified fiber and polypropylene, which is applied in the field of dyeable polypropylene modified fiber, which can solve the problems of being difficult to adapt to the diversity of clothing fabrics and restricting the variety of fabrics, achieving excellent dyeing rate, improving extensibility and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

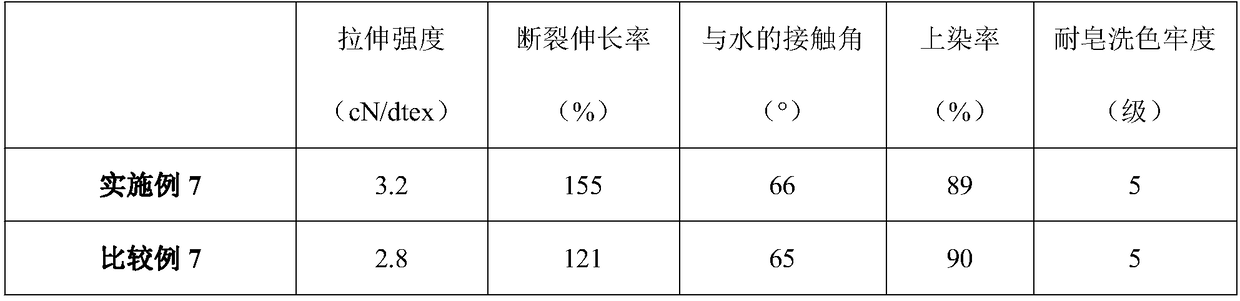

Examples

Embodiment 1

[0021] With 0.25wt% polypropylene resin F280, 1.0wt% titanium tetraacetylacetonate, 3.9wt% polyvinylpyrrolidone, 0.2wt% antioxidant 1010, 0.8wt% light stabilizer UV-531 and the rest Polypropylene resin Y1600 was used as the raw material, and the above-mentioned raw materials were mixed uniformly and then extruded and granulated in a screw extruder at 220° C. to obtain the polypropylene blended resin of this embodiment. The above-mentioned polypropylene fiber blended resin was spun in a spinning equipment at a temperature of 260°C, a spinning speed of 1000m / min, a hot roll temperature of 65°C, and a draw ratio of 3 times.

Embodiment 2

[0023] With 0.15wt% polypropylene resin F280, 1.2wt% titanium tetraacetylacetonate, 2.8wt% polyvinylpyridine, 0.2wt% antioxidant 1010, 0.8wt% light stabilizer UV-531 and the balance The polypropylene resin Y1600 was used as the raw material, and the above-mentioned raw materials were mixed uniformly and then extruded and granulated in a screw extruder at 220° C. to obtain the polypropylene blended resin of this embodiment. The above-mentioned polypropylene fiber blended resin was spun in a spinning equipment at a temperature of 260°C, a spinning speed of 1000m / min, a hot roll temperature of 65°C, and a draw ratio of 3 times.

Embodiment 3

[0025] With 0.20wt% polypropylene resin F280, 0.9wt% titanium tetraacetylacetonate, 3.2wt% polyethyleneimine, 0.2wt% antioxidant 1010, 0.8wt% light stabilizer UV-531 and the balance The polypropylene resin Y1600 was used as the raw material, and the above-mentioned raw materials were mixed uniformly and then extruded and granulated in a screw extruder at 220° C. to obtain the polypropylene blended resin of this embodiment. The above-mentioned polypropylene fiber blended resin was spun in a spinning equipment at a temperature of 260°C, a spinning speed of 1000m / min, a hot roll temperature of 65°C, and a draw ratio of 3 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt mass flow rate | aaaaa | aaaaa |

| Melt mass flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com