Low-wear air conditioner compressor

An air-conditioning compressor and low-wear technology, applied in the field of compressors, can solve the problems of wear, low efficiency, and high cost of rotating rollers and cylinders, and achieve the effects of reducing cylinder wear, reducing wear, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

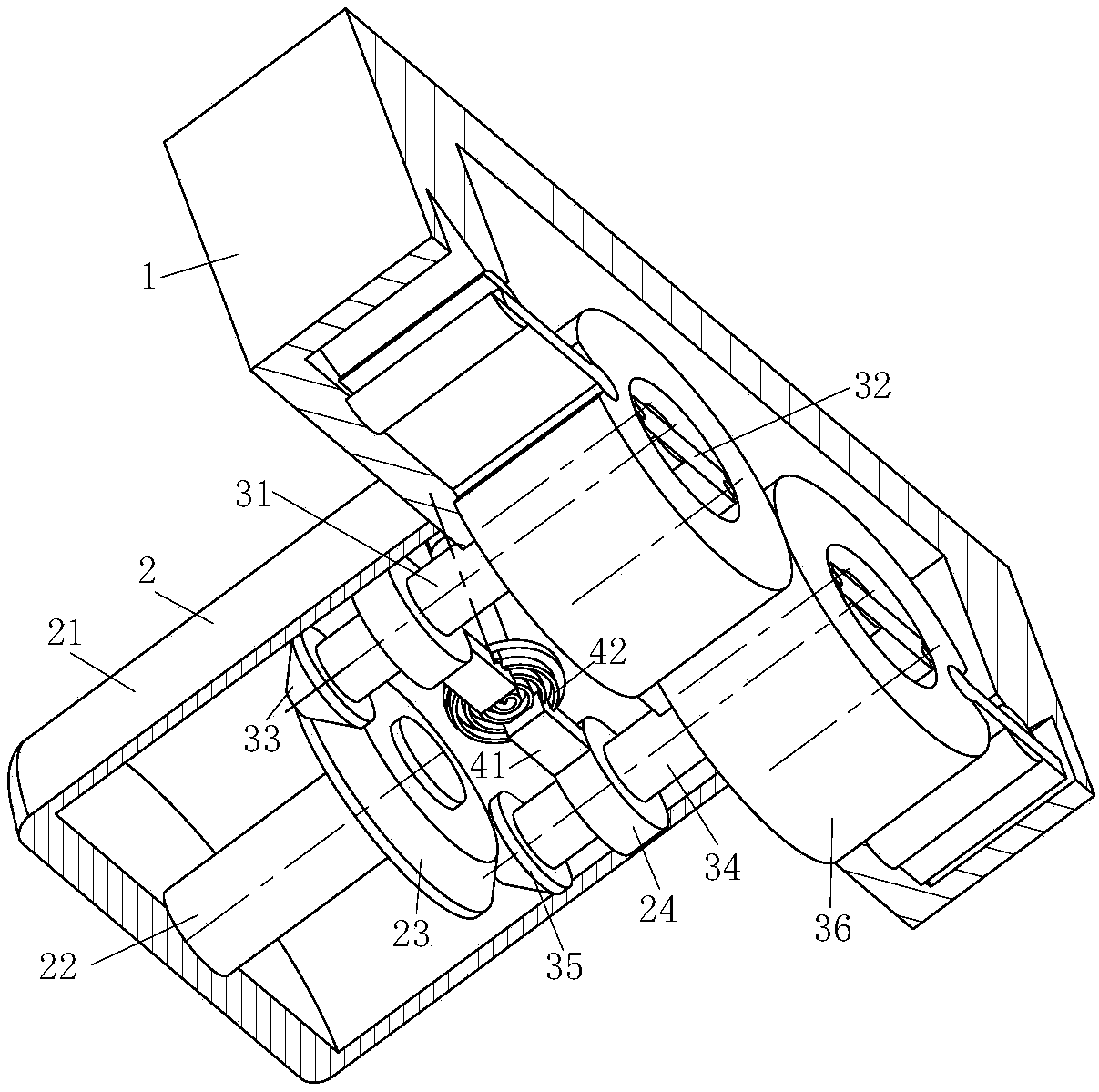

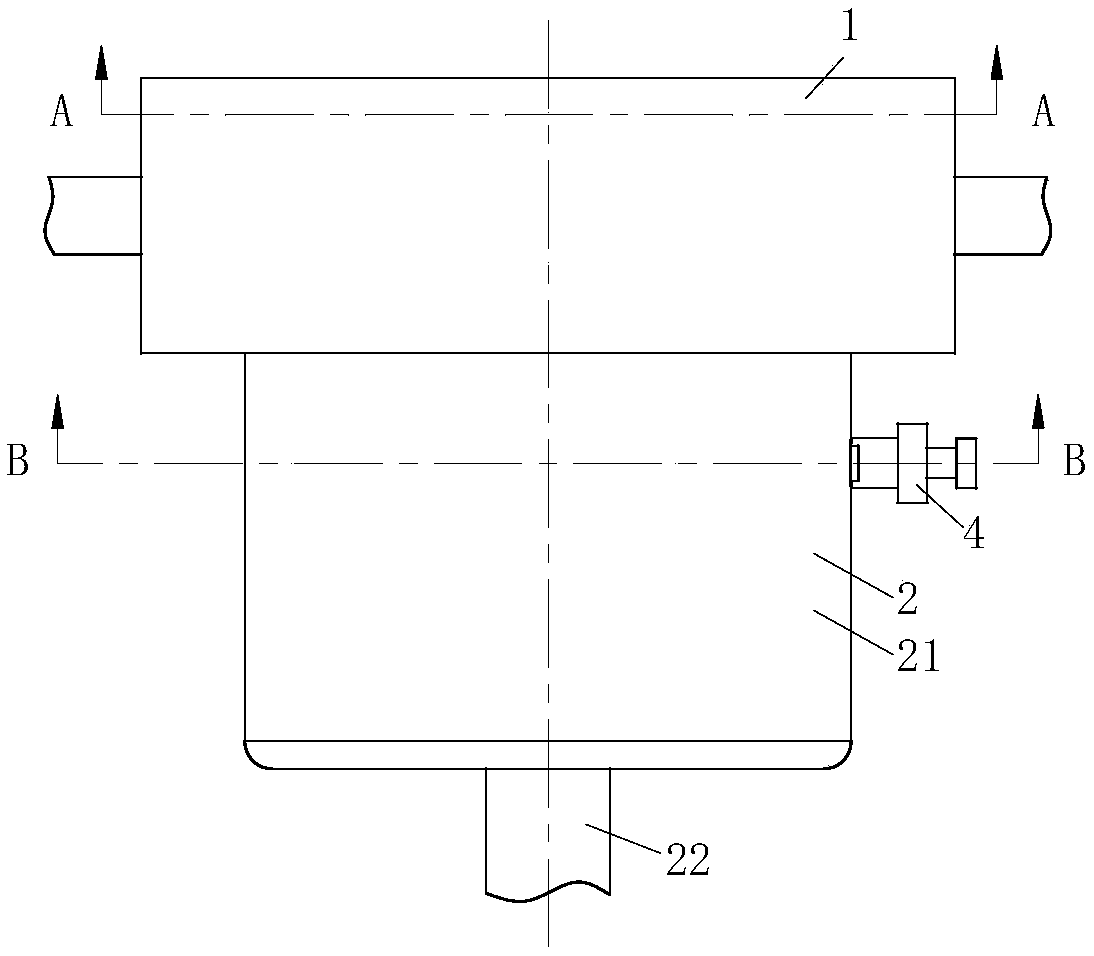

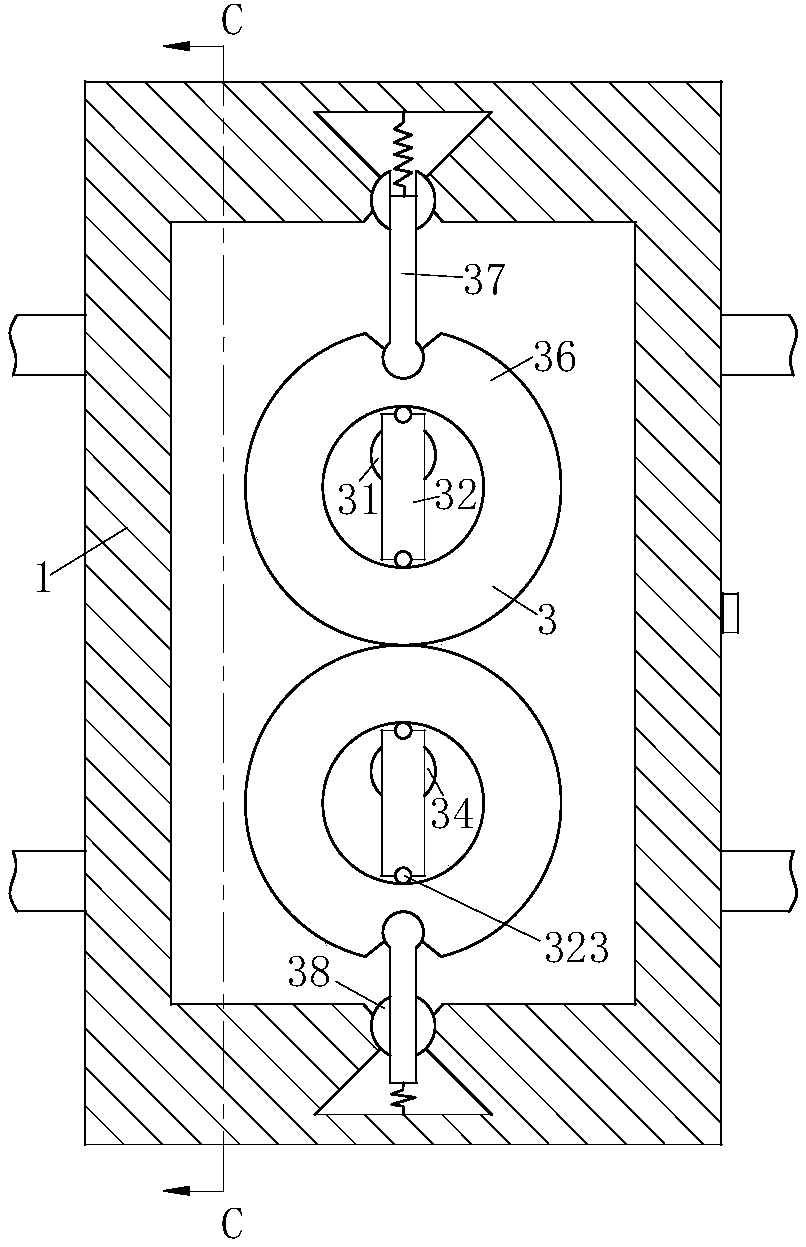

[0034] As an embodiment of the present invention, the middle parts of the first eccentric shaft 31 and the second eccentric shaft 34 are rotatably connected to the cylinder 1 through the second bearing 25, and the outer ring of the second bearing 25 is provided with a buffer elastic rubber ring 26 , used to coordinately adjust the distance between the first eccentric shaft 31 and the second eccentric shaft 34 to realize wear compensation.

[0035] As an embodiment of the present invention, an oil cavity is provided inside the eccentric block 32; a first oil injection hole 321 and a second oil injection hole 322 are provided on both sides of the oil cavity; both ends of the eccentric block 32 are rotatably mounted With the second roller 323, the friction between the eccentric block 32 and the rotor 36 is reduced, and the service life of the machine is improved.

[0036] As an embodiment of the present invention, the diameter of the first oil injection hole 321 is set to 2-3 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com