Deicing device of liquid natural gas output pipeline

A liquid natural gas and output pipeline technology, applied in the geometry/arrangement/dimension of container structure, pipe components, fixed-capacity gas storage tanks, etc., can solve problems such as damage to gas output pipelines, and achieve convenient installation and disassembly processes. Contact area, effect of reducing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

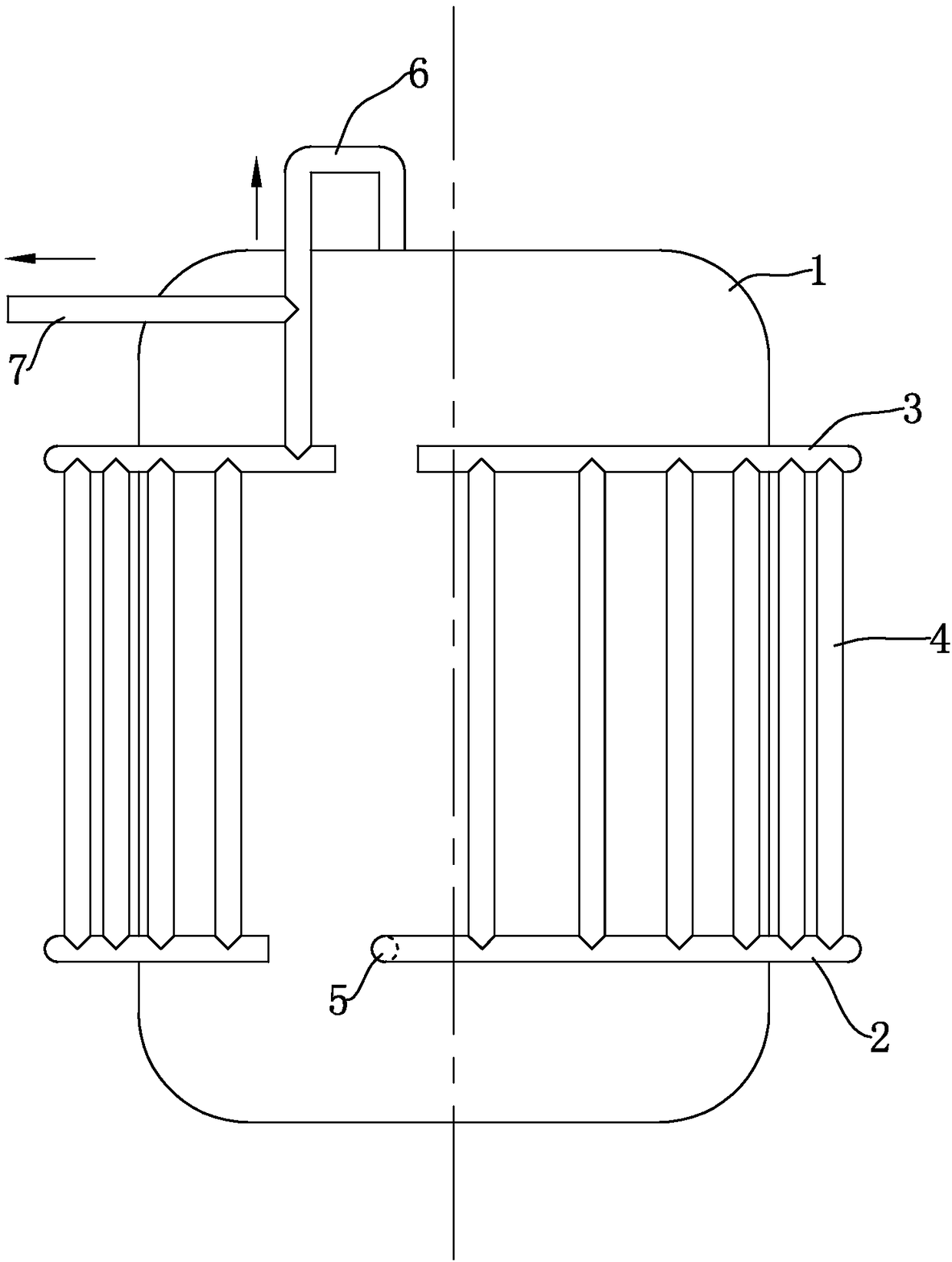

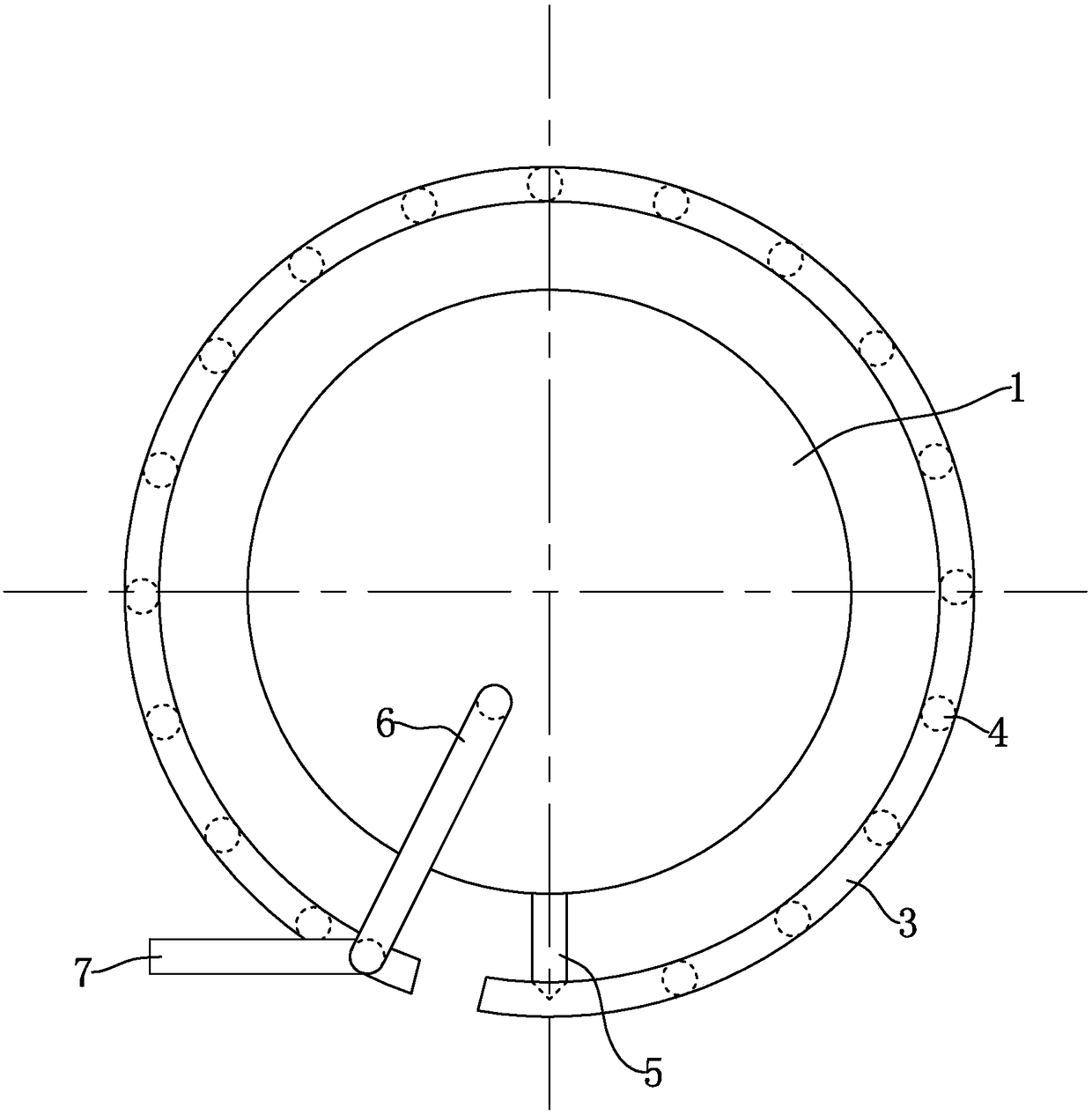

[0057] In order to facilitate the understanding of the present invention, the structure and working principle of the prior art will be briefly described first. Such as figure 1 with figure 2 As shown, the liquid natural gas storage tank 1 is surrounded by a gas outlet pipe assembly. The gas outlet pipe assembly includes a horizontally arranged gas outlet pipe 2 and an upper outlet pipe 3. Both the gas outlet pipe 2 and the upper outlet pipe 3 have disconnected gaps. The ring shape is arranged around the liquid natural gas storage tank 1; a transition pipe 4 is provided between the gas output pipe 2 and the upper output pipe 3, and the gas output pipe 2 and the upper output pipe 3 are connected through the transition pipe 4, and the transition pipe 4 are vertically arranged, and there are multiple transition pipes 4 that are evenly distributed around the circumference of the liquid natural gas storage tank 1. One end of the gas output pipe 2 is fixedly connected with a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com