Semiconductor laser chip package precision detection method and device

A technology for chip packaging and precision testing, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that do not involve the detection function of semiconductor laser chip packaging precision, does not involve the detection function of chip packaging precision, etc., and achieves fast detection speed , Good detection effect, accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

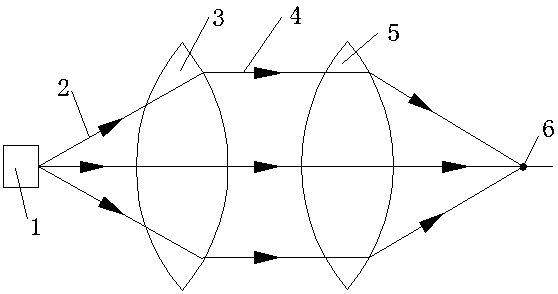

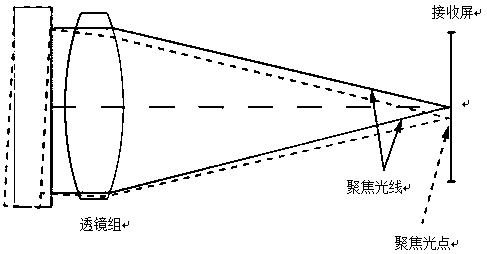

[0024] The present invention utilizes the convex lens to have light-gathering effect on the light, and realizes that the elliptical light shape emitted by the laser is focused after passing through the convex lens; according to the shape difference of the focused light spot of different light-emitting points after being focused by two convex lenses, it is detected near the focal point The shape of the light spot can realize the detection of the accuracy of the position of the laser light-emitting point—that is, the detection of the packaging accuracy of the laser chip.

[0025] like figure 1 As shown, the emitted light 2 of the semiconductor laser 1 will become parallel light 4 after passing through the first convex lens 3 , and the light after the parallel light 4 is focused by the second convex lens 5 finally becomes a focused light spot 6 on the receiving screen.

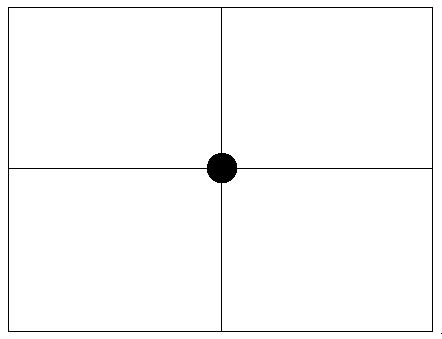

[0026] Ideally, the light emitting point of the chip is located on the optical axis of the convex lens, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com