A full-dimensional safety protection method for explosive force-heat composite loading

A safety protection and thermal compounding technology, applied in temperature control, instruments, control/regulation systems, etc., can solve problems such as doubts about the strength and effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

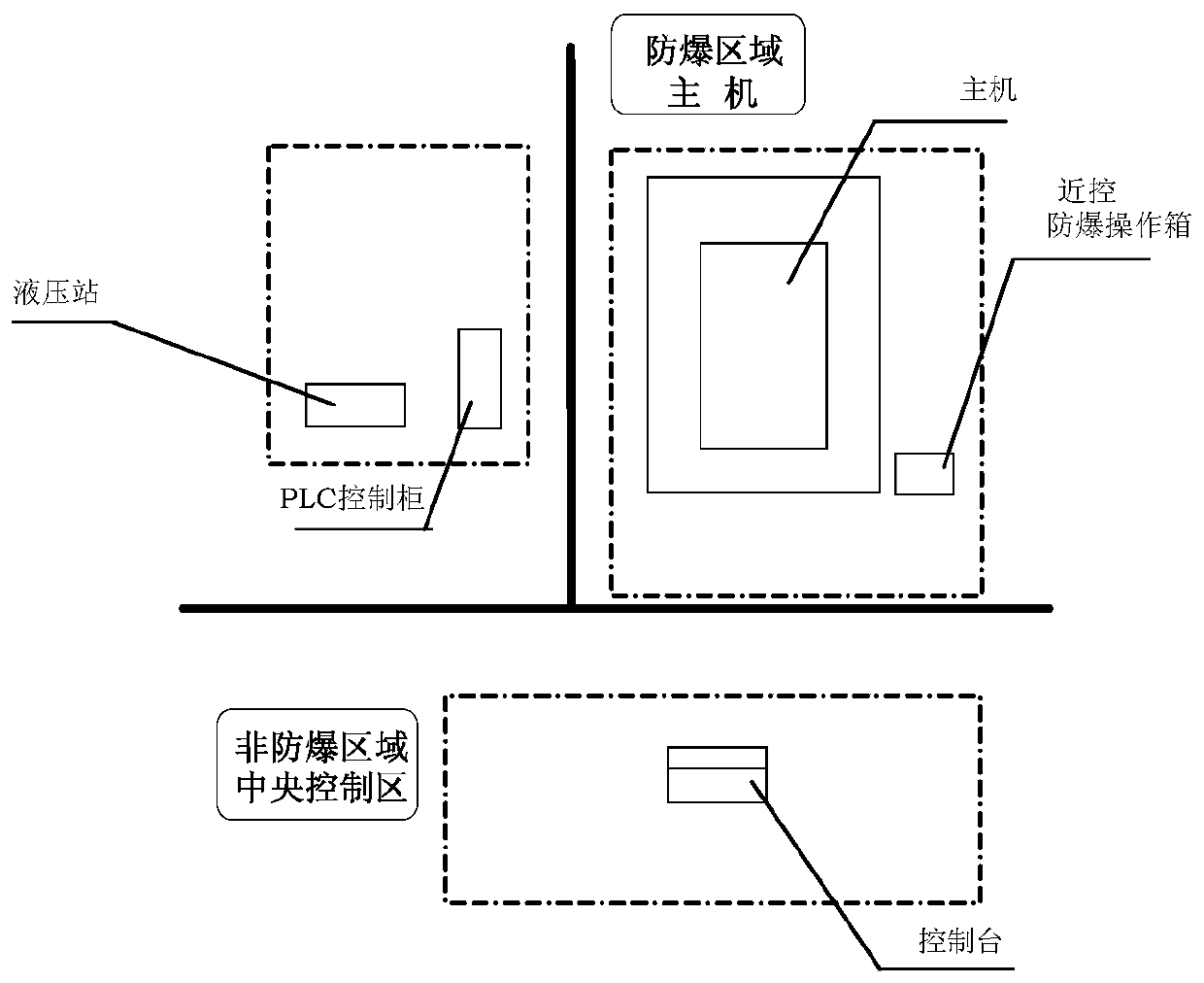

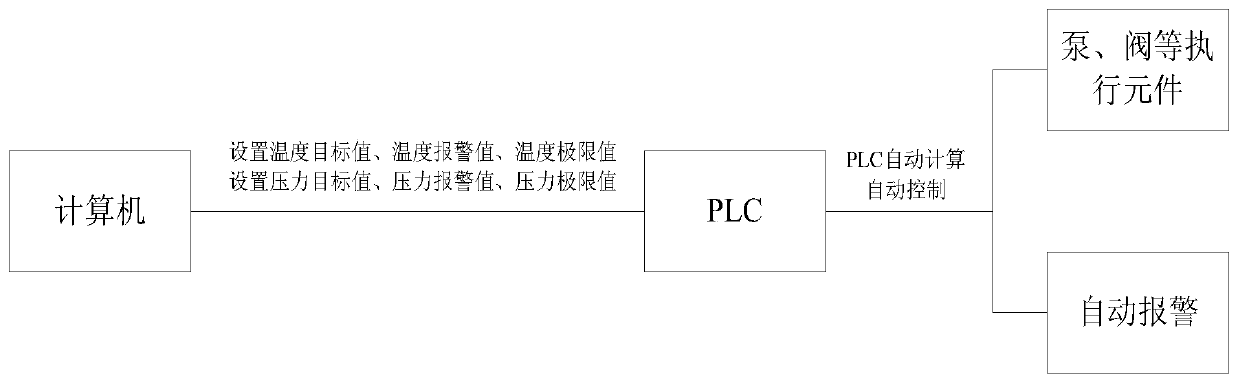

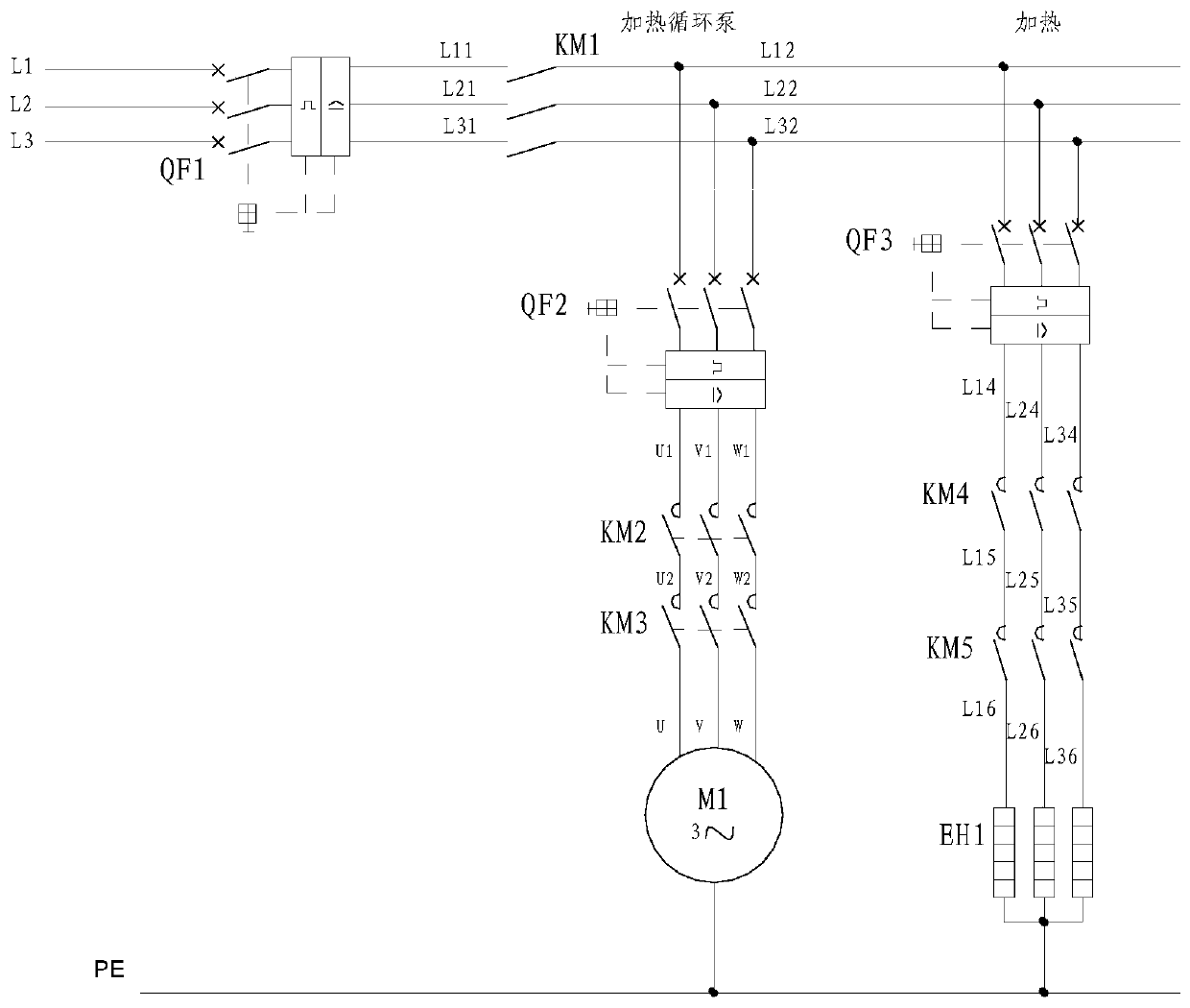

[0040] as attached figure 1 As shown, a full-dimensional safety protection system loaded with explosive force and heat composite, including:

[0041] Explosion-proof isolation design, the main engine is set in the explosion-proof room, the hydraulic station, control cabinet, and console are set in the non-explosion-proof room, and the explosion-proof operation box is installed in the explosion-proof room. The temperature, pressure, and displacement sensor cables on the main engine pass through the explosion-proof flexible The pipe enters the explosion-proof connection box and connects to the control cabinet.

[0042] In the safety protection system of the present invention, the force-heat composite loading equipment is designed to be explosion-proof and isolated according to the degree of danger. The main engine will be equipped with explosive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com