Integrated X-ray generating device

A technology for generating devices and X-rays, applied in X-ray equipment, electrical components, etc., can solve the problems of complex installation, debugging and use, bulky split structure, socket discharge breakdown, etc., to eliminate high-voltage discharge or breakdown problems. , The debugging process is simple, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

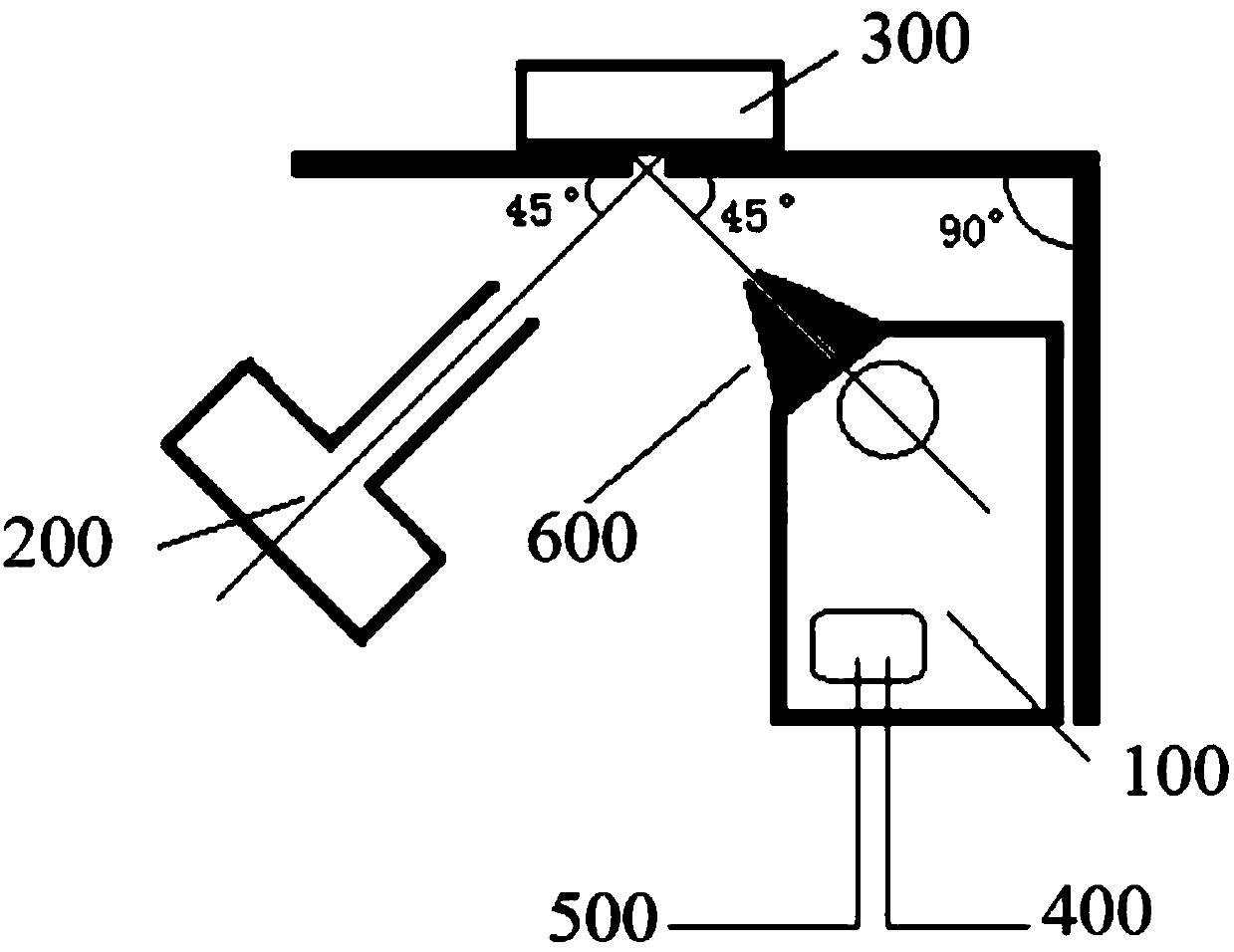

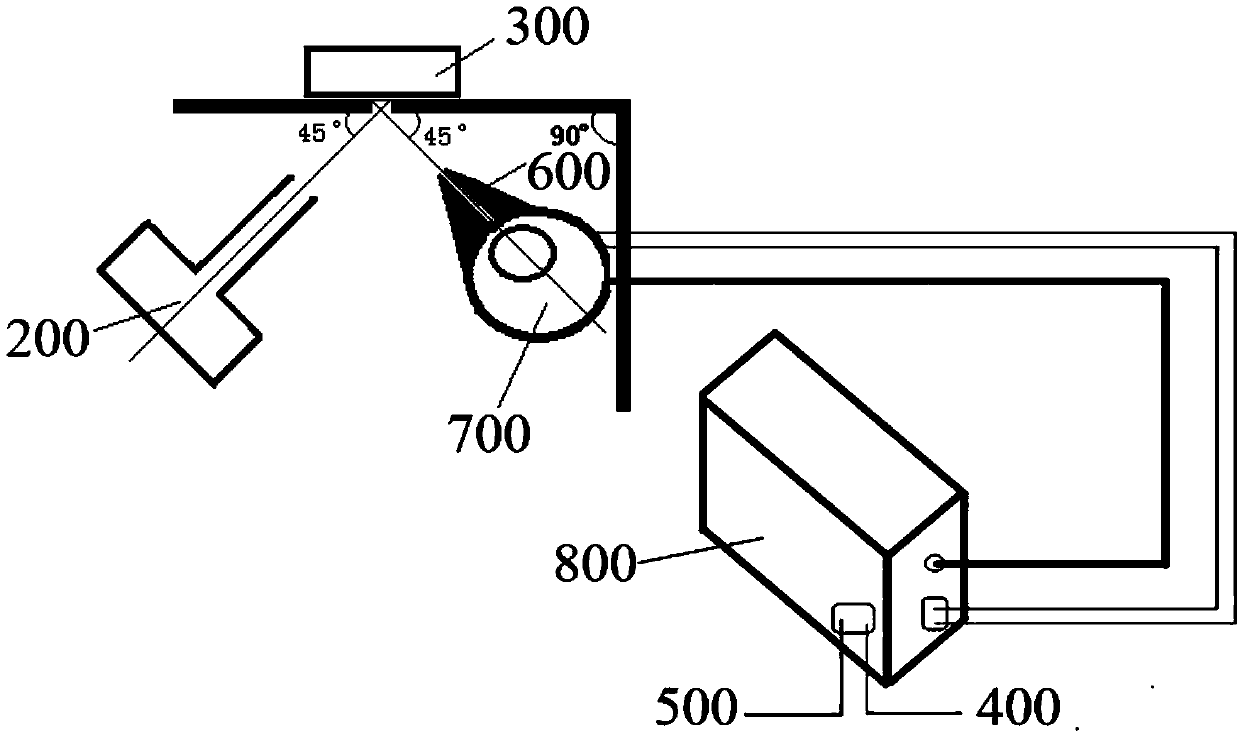

[0044] figure 1 It is an embodiment of the present invention. For a fluorescence detection device, the present invention provides an integrated X-ray generating device to replace the original device. The original device such as figure 2 As shown, the X-ray part of the original device is composed of two parts, namely X-ray tube 700 and high-voltage power supply 800, wherein X-ray tube 700 is mainly composed of X-ray lamp tube, transformer oil, high-voltage socket, cylindrical shell, etc. The high-voltage power supply 800 is composed of a control board, a high-voltage doubler board, an electronic potting compound, a high-voltage socket, and a casing. The two are connected by high-voltage wires and filament wires, especially the high-voltage wires and high-voltage plugs often have sparks, discharges, and breakdowns. phenomenon, causing other parts of the equipment to be injured and penetrated by accident, and more importantly, causing shock or injury to the operator. However, wh...

Embodiment 2

[0060] The present invention is aimed at a fluorescent detection desktop device. The original minimum equipment size is about 500 mm in length, 450 mm in width, and 350 mm in height. Since this type of equipment is located in the counter of a shopping mall, its structure is complicated and heavy, and it will be difficult for users. bring inconvenience.

[0061] After installing the integrated X-ray generating device, the approximate size of the equipment is 350 mm in length, 300 mm in width and 300 mm in height, which makes the equipment more portable.

[0062] The integrated X-ray generating device of the present invention includes a main body frame 4, an X-ray tube assembly 1, a high-voltage doubler circuit board 6, a flange 11, a bracket 5, an insulating board 7, a copper connection terminal 2, a control board 9, a temperature coefficient expansion Condenser 3, panel 12, back cover 8, pressure ring form.

[0063] The design idea of the present invention is to design a on...

Embodiment 3

[0076] General field flaw detection devices are usually carried to the use site, and then assembled, so the equipment is as light as possible, miniaturized, and easy to operate. If it is too heavy, the operation is troublesome, so there are requirements for the operator. It is also a test for them.

[0077] The integrated X-ray generating device of the present invention includes a main body frame 4, an X-ray tube assembly 1, a high-voltage doubler circuit board 6, a flange 11, a bracket 5, an insulating board 7, a copper connection terminal 2, a control board 9, a temperature coefficient expansion Condenser 3, panel 12, back cover 8, pressure ring form.

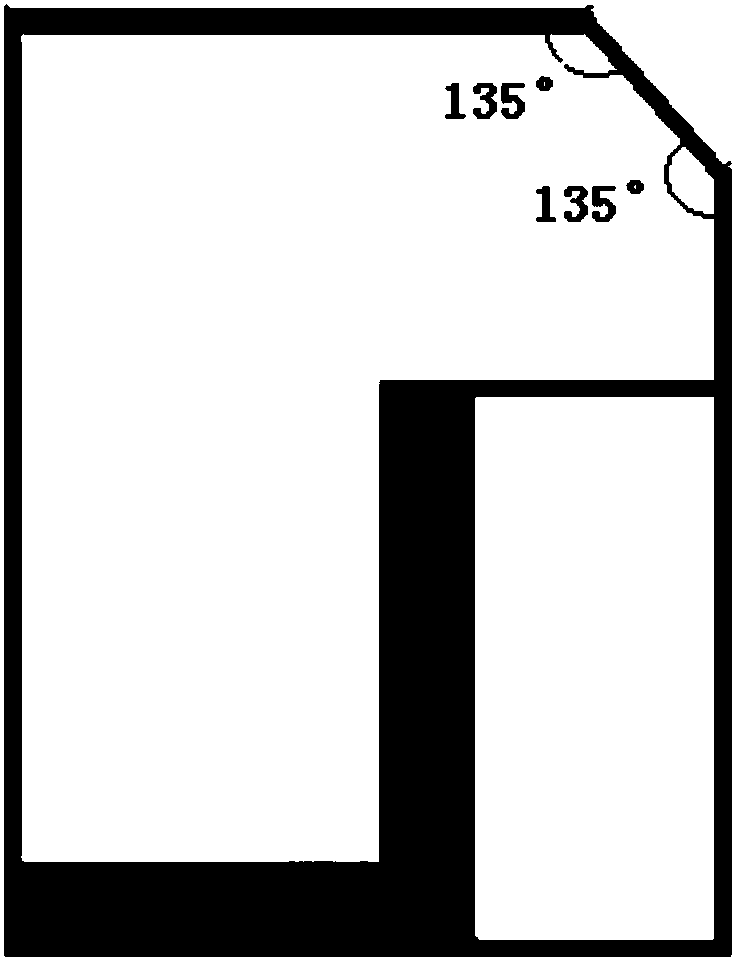

[0078] The design idea of the present invention is to design a one-time extruded abrasive tool, and use the abrasive tool to extrude and process the main frame 4. The main frame 4 is a one-time formed extruded aluminum part. They are all concave, divided into upper concave and lower concave. The upper concave position is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com