Intelligent side-in type stirrer capable of replacing shaft seal with raw materials

A side-entry mixer technology, applied in the field of side-entry mixers for kettles, can solve problems such as mechanical seal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

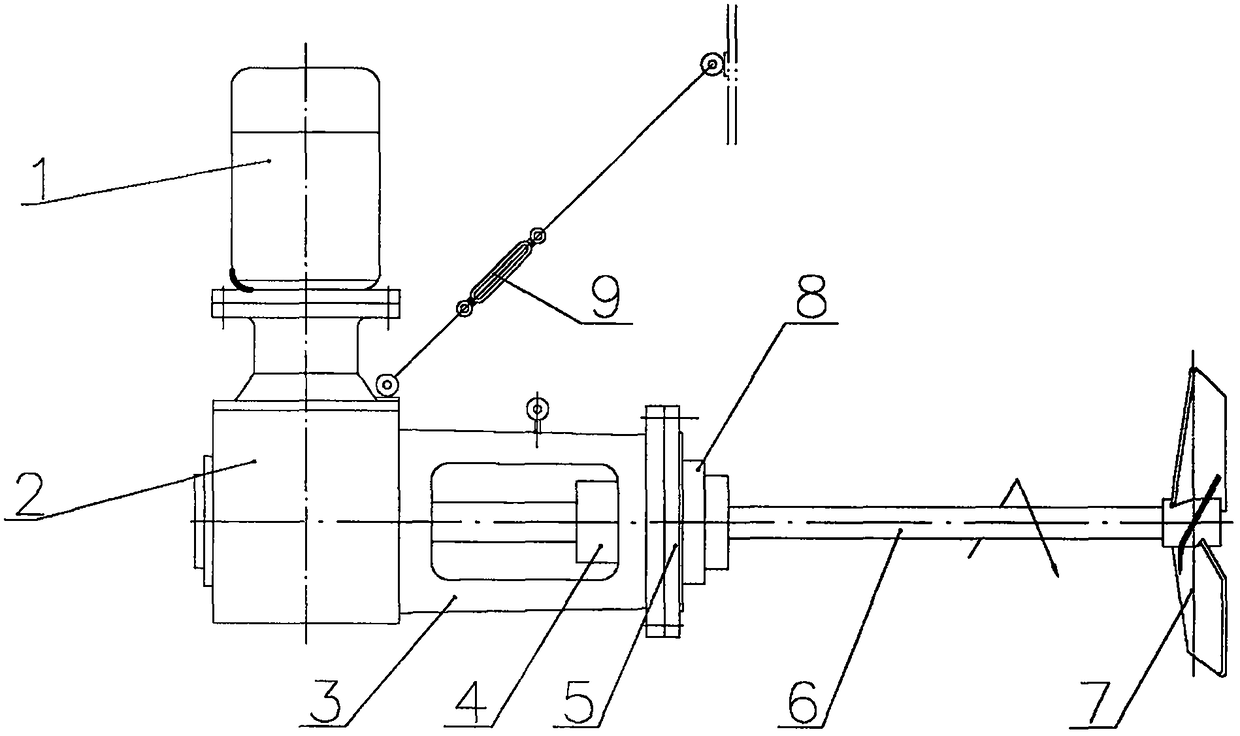

[0016] Such as figure 1 Shown:

[0017] Intelligent side-entry mixer that can replace shaft seal with material, including motor 1, reducer 2, frame 3, mechanical seal 4, mounting flange 5, stirring shaft 6, stirrer 7, blocking device 8 and stabilizing device 9 . The reducer 2 is fixed outside the side wall of the kettle through the frame 3 and the mounting flange 5, the motor 1 is installed on the input end of the reducer 2, and the stirring shaft 6 is also the output shaft of the reducer 2 that goes deep into the kettle and is installed in the kettle. The agitator 7 is installed, and the stabilizing device 9 is used for load-bearing to improve the stressed state of the agitator.

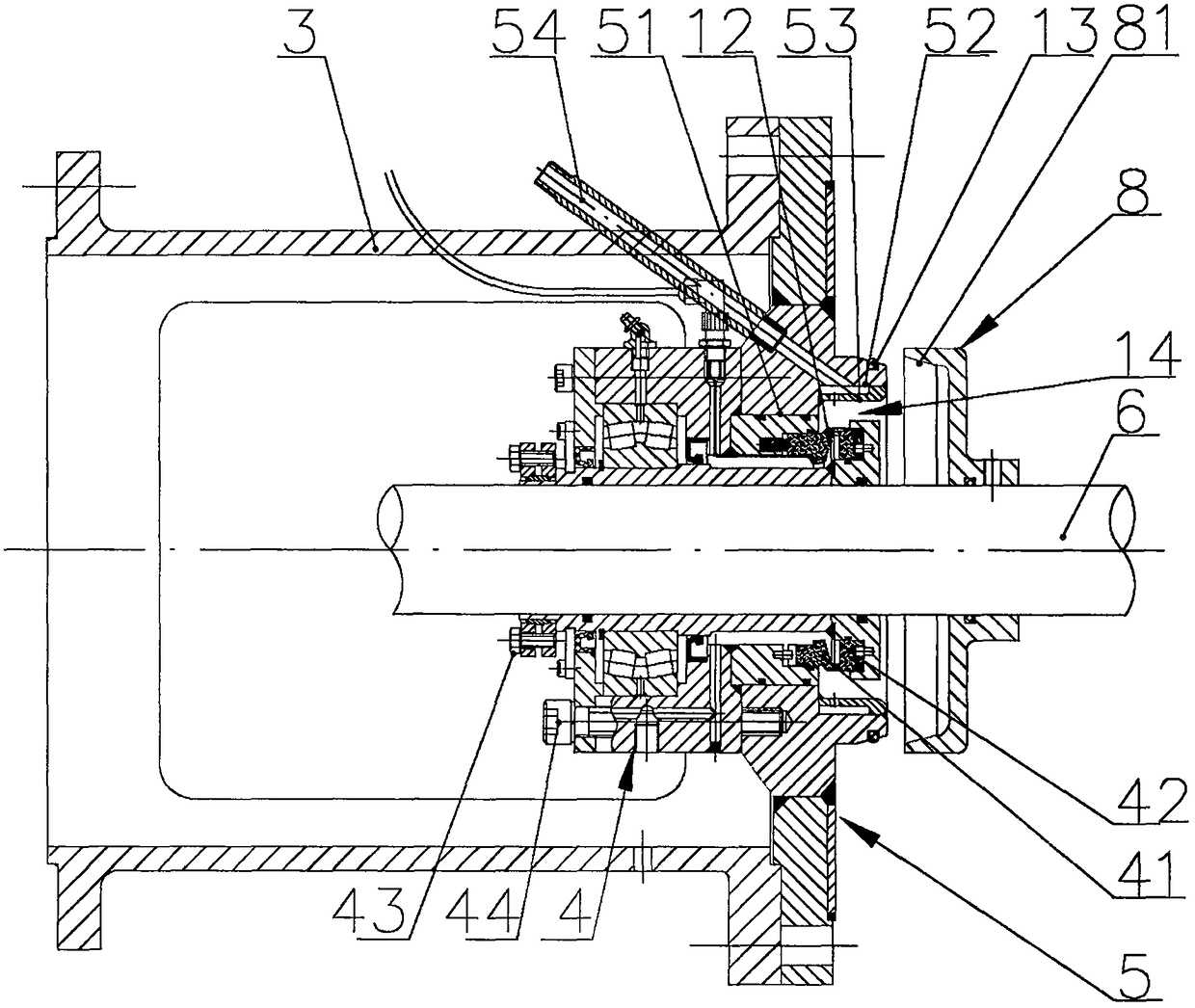

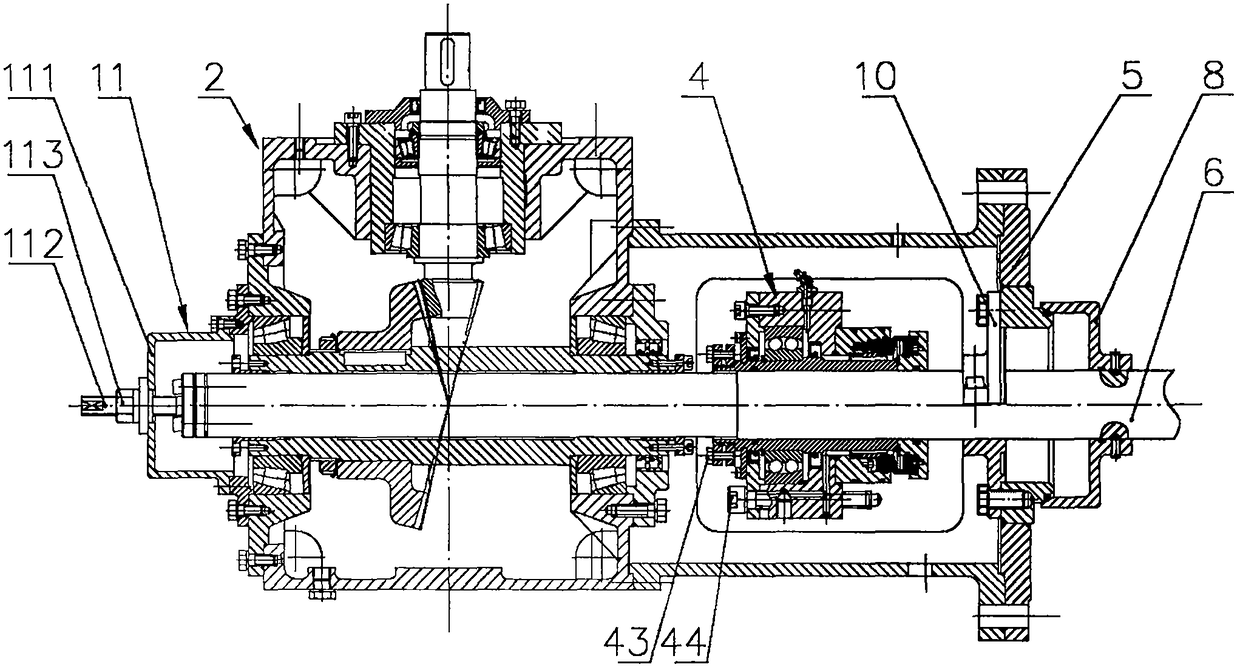

[0018] Such as figure 2 Shown:

[0019] The inner hole of the mounting flange 5 is a stepped hole, the small diameter section 51 is tightly matched with the installation cylinder of the mechanical seal 4, and the inner side of the large diameter section 52 is designed with a flushing water dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com