A construction method for sealing a hole with a combination of profiled steel beams and profiled steel plates

A profiled steel plate and construction method technology, which is applied in the direction of buildings, building components, and housing structure support, can solve the problems of sealing holes, such as improving the structural strength of new and old plates, and improving construction efficiency and safety, and improving integrity , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical requirements for the cutting and hoisting construction of shaped steel beams and flat steel beams, the technical requirements for on-site welding construction, the technical requirements for concrete mix design and pouring construction, etc., will not be described in detail in this embodiment, and the embodiments related to structures in the present invention will be focused on.

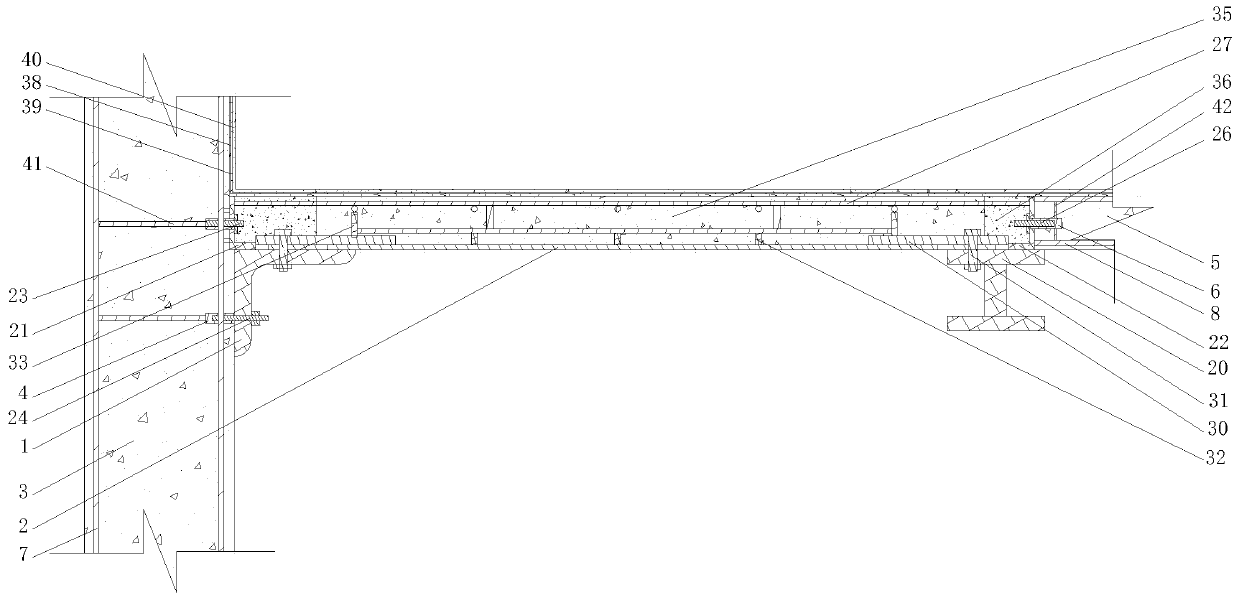

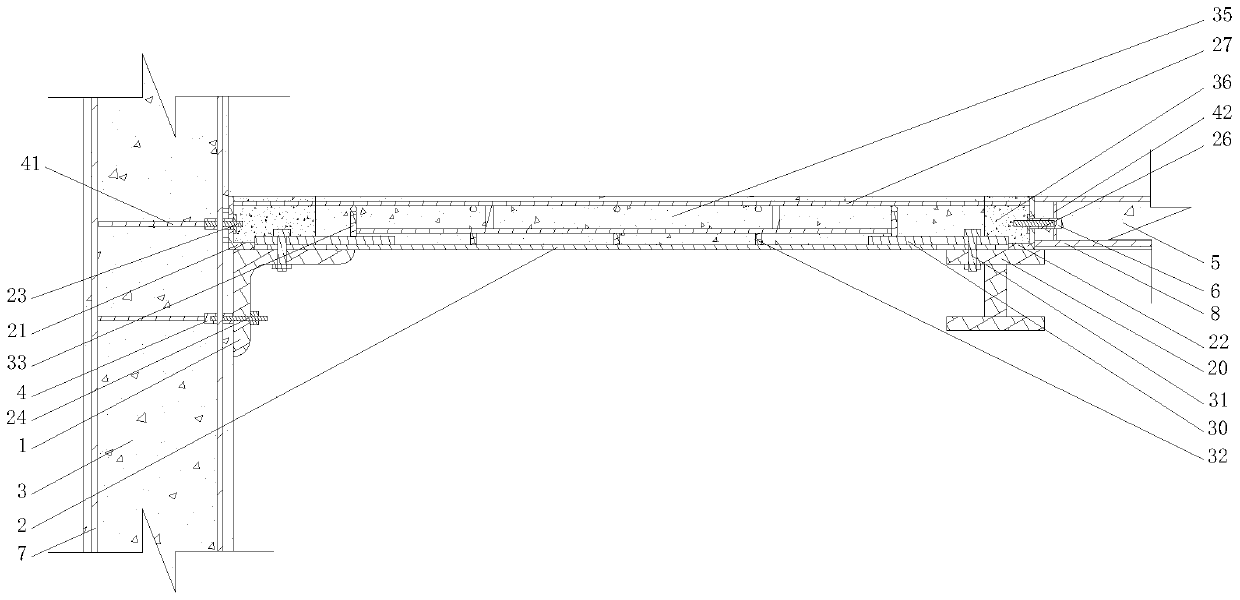

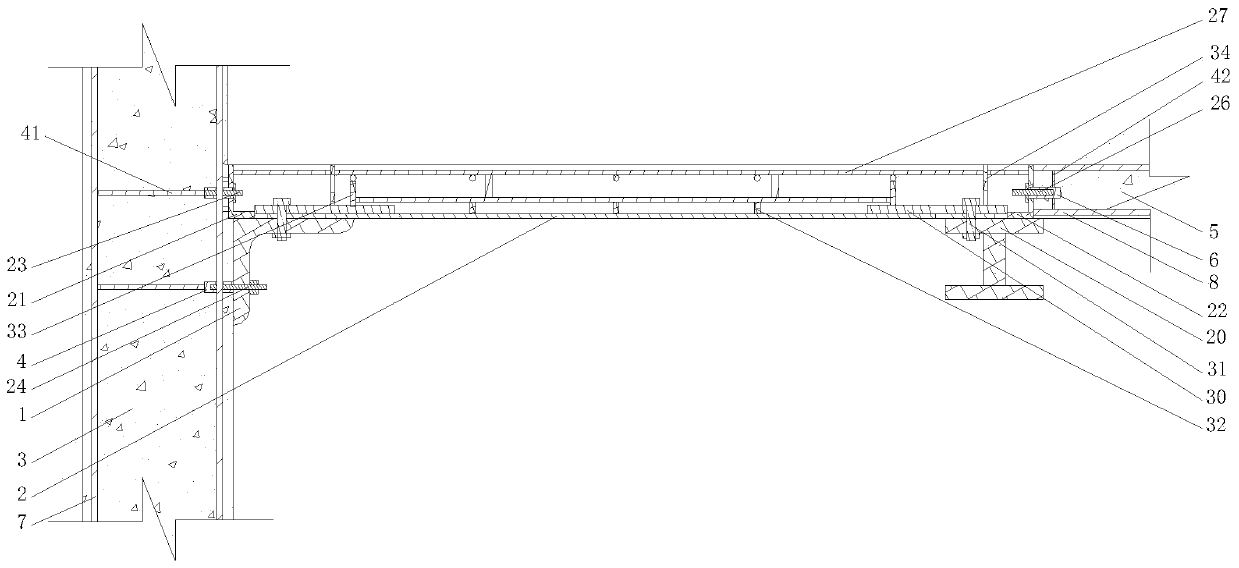

[0036] figure 1 It is a cross-sectional schematic diagram of the construction of a combination of shaped steel beams and profiled steel plates to block the opening of the present invention. figure 2 yes figure 1 Schematic diagram of the cross-section after the concrete pouring of the floor slab at the opening, image 3 yes figure 1 Schematic diagram of the cross-section after the profiled steel plate and reinforcement cage are laid out, Figure 4 yes figure 1 Schematic diagram of the lifting construction of shaped steel beams and flat steel beams, Figure 5 yes figure 1 Sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com