Combined type steel structure reaction frame

A technology of reaction force frame and steel structure, which is applied in the field of multifunctional combined steel structure reaction force frame, can solve problems such as inability to adapt the direction of reaction force application, and achieve the effects of convenient assembly, disassembly and transportation, complete functions and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

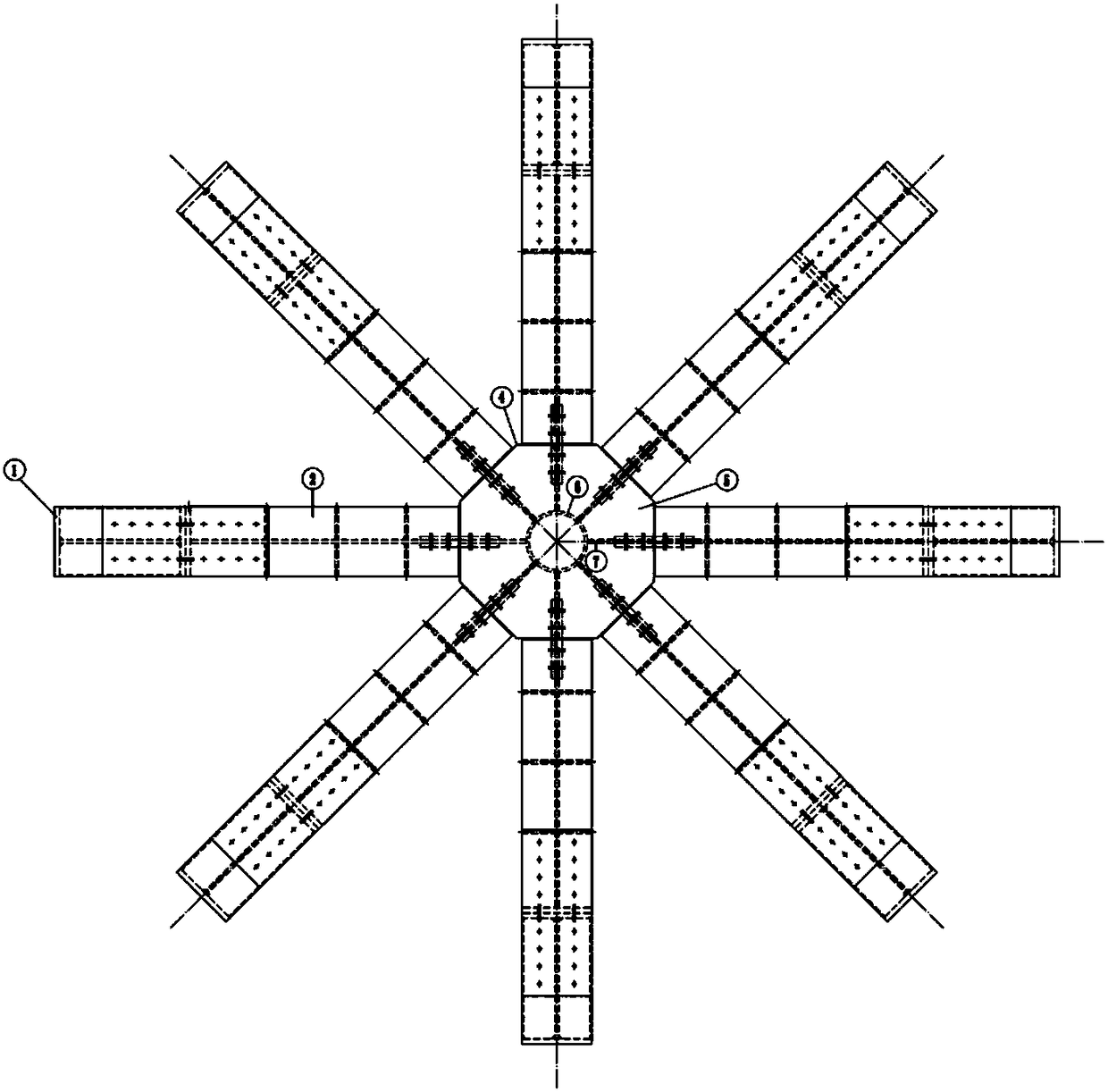

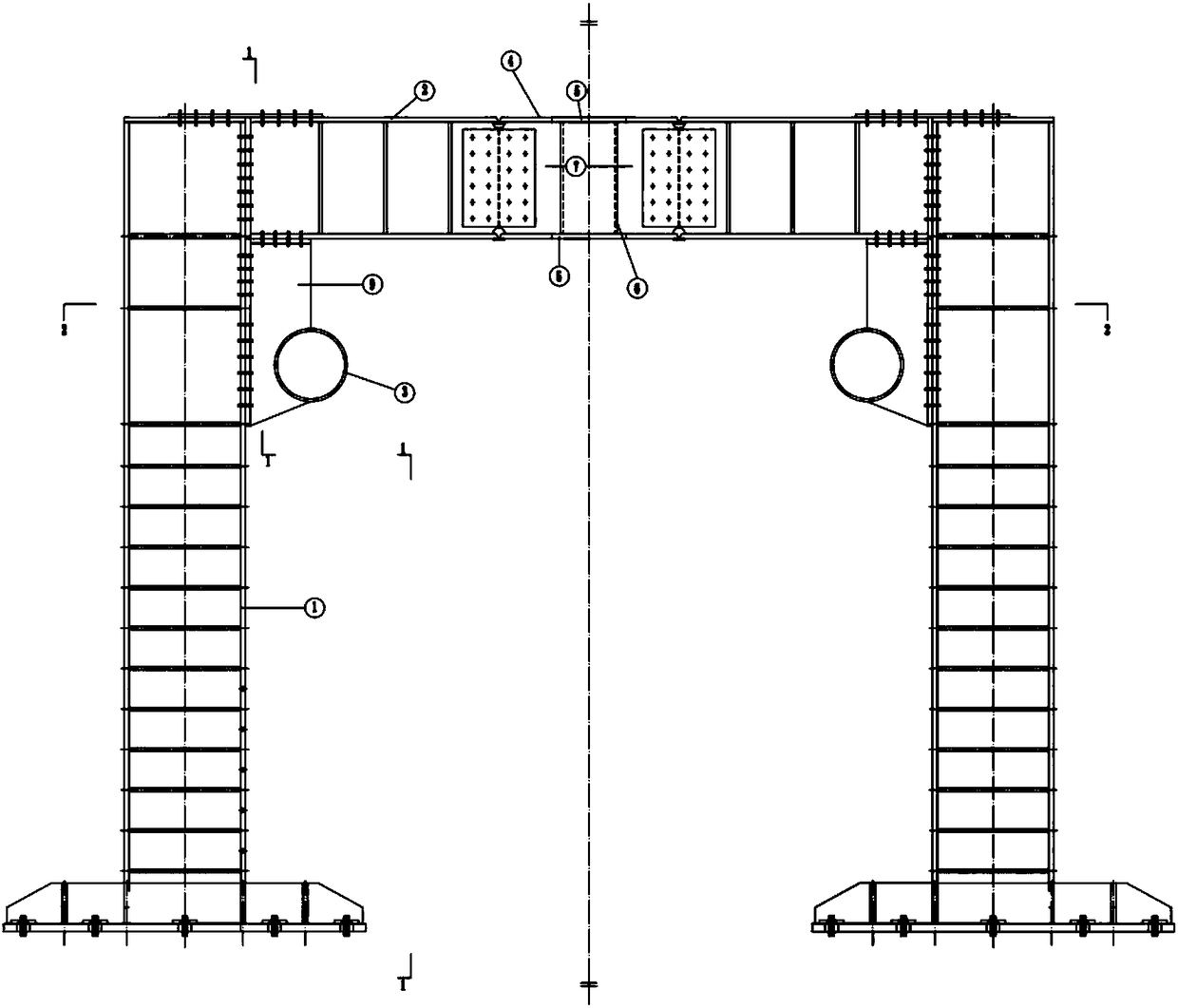

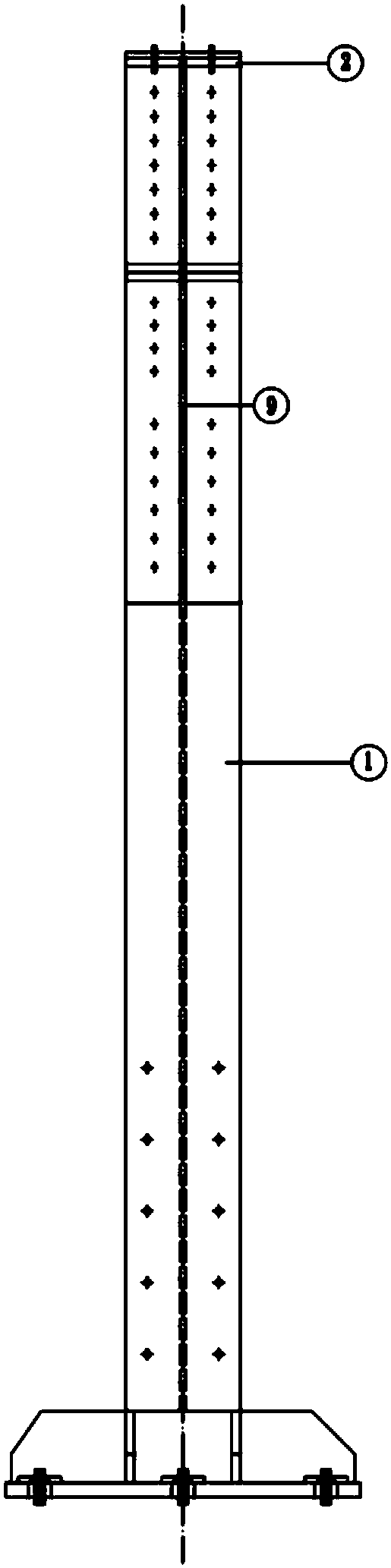

[0018] like figure 1 , figure 2 and Figure 4 Shown: a multi-functional combined steel structure reaction frame, including a portal reaction frame 1, a ring beam 3, a top composite member 4 and a slider 8, and the portal reaction frame takes the centroid of the top composite member 4 as the center of the circle , 45° angle array setting, the top composite member 4 is connected with each door-type reaction frame beam 2 through a bolt-welding hybrid method. A steel plate 9 is welded at the bottom of each gate-type reaction force frame beam 2, and the ring beam 3 is connected with the steel plate 9 by welding. The slide block 8 realizes sliding and rotation on the ring beam 3 by loosening and tightening high-strength bolts.

[0019] The column and beam of the portal reaction frame are connected by the method of bolt end plate, such as figure 1 and figure 2 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com