Interconnection structure and manufacturing method thereof

A technology of interconnection structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., to achieve the effect of maintaining low resistance value and low resistance capacitance delay, preventing circuit bridging defects, and large cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

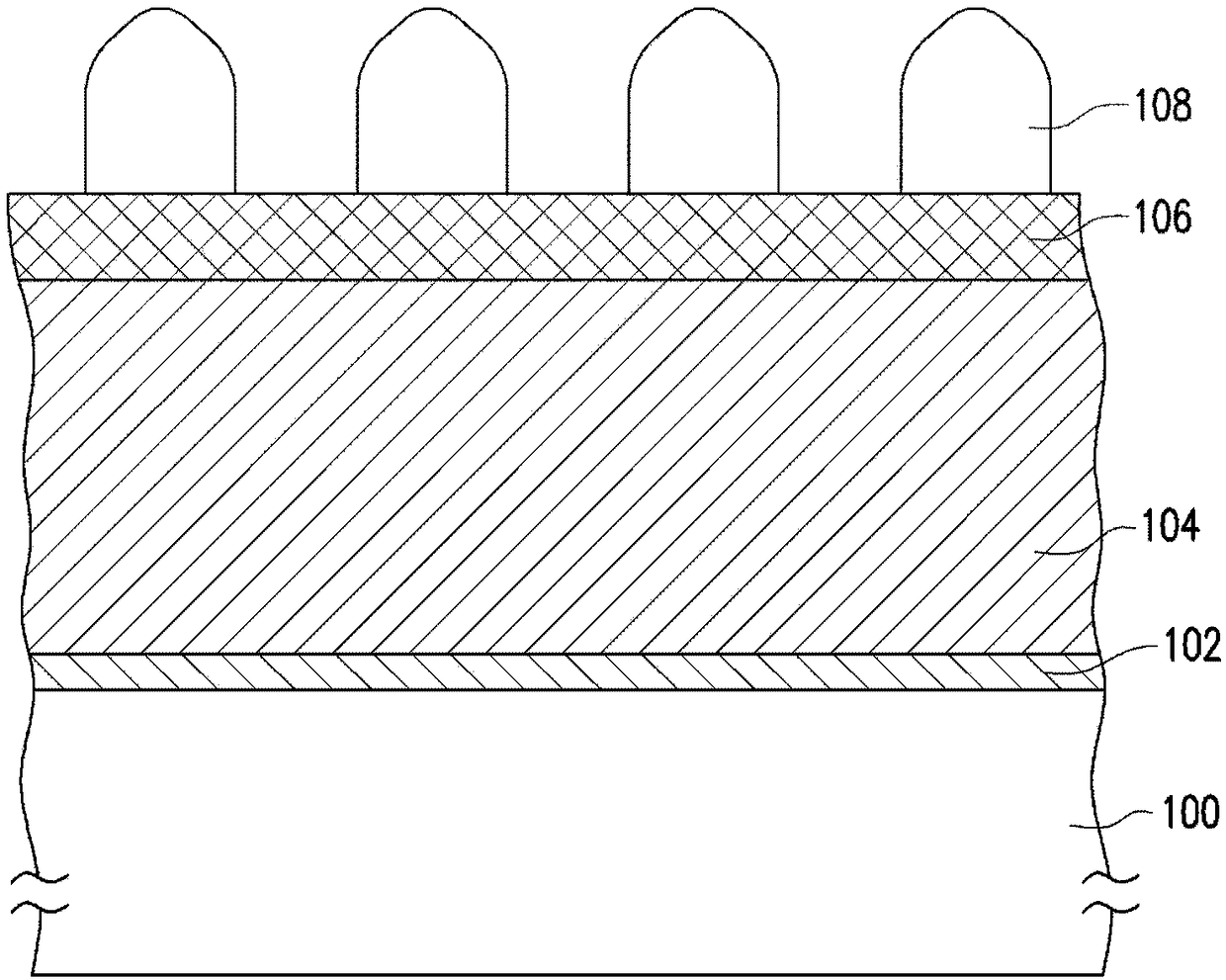

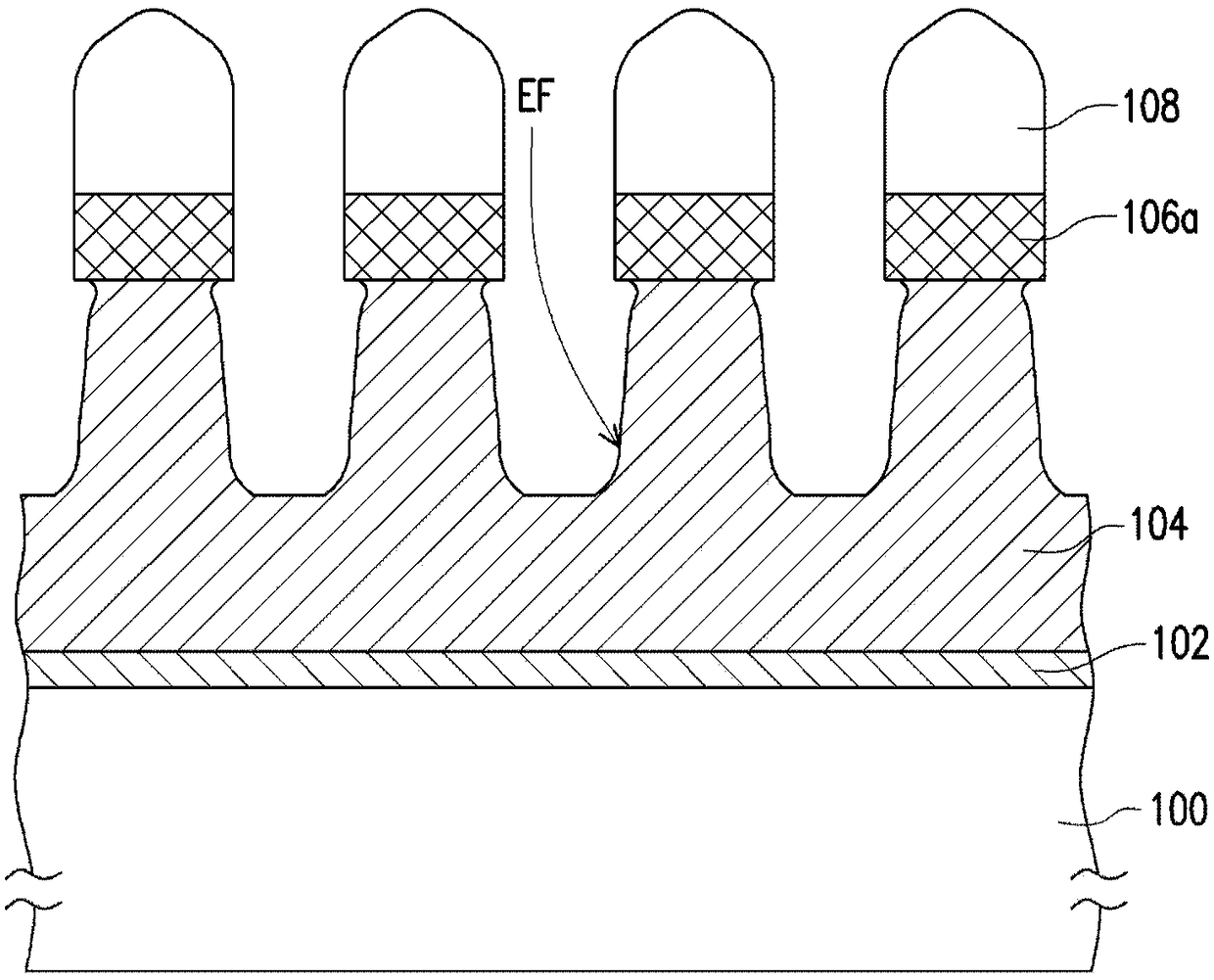

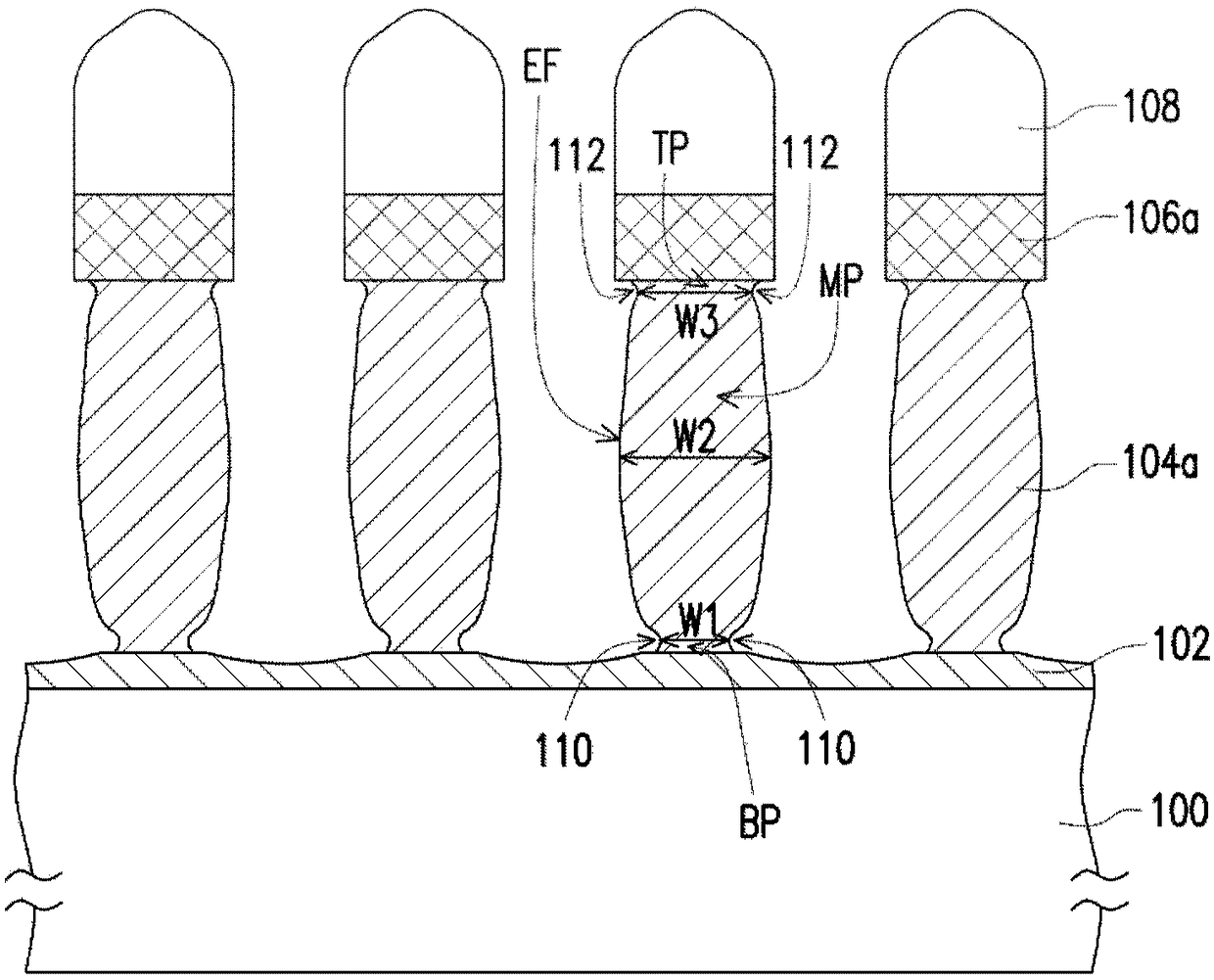

[0035] Figure 1A to Figure 1E It is a sectional view of the manufacturing process of the interconnection structure according to an embodiment of the present invention.

[0036] First, please refer to Figure 1A , providing a substrate 100. The substrate 100 can be a single-layer substrate or a multi-layer substrate, and other film layers (not shown), conductive elements (not shown) or semiconductor elements (not shown) can be formed thereon.

[0037] Next, a barrier material layer 102 can be optionally formed on the substrate 100 . The material of the barrier material layer 102 is, for example, Ti, TiN, Ta, TaN or a combination thereof. The barrier material layer 102 is formed by, for example, physical vapor deposition or chemical vapor deposition.

[0038] Then, a conductive pattern material layer 104 is formed on the barrier material layer 102 . The material of the conductive pattern material layer 104 is, for example, AlCu, Al or W. The method for forming the conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com