Formation method of semiconductor structure and mask

A semiconductor and mask technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of increasing the difficulty and complexity of integrated circuits, achieve small changes, low process complexity, and meet high density and highly integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

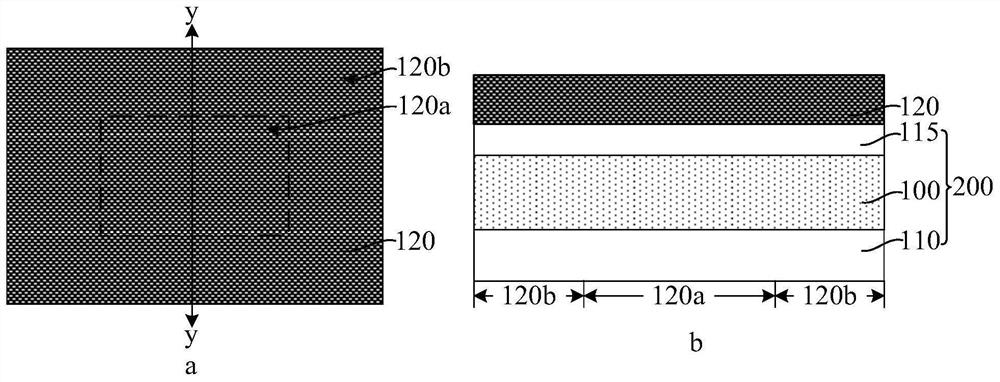

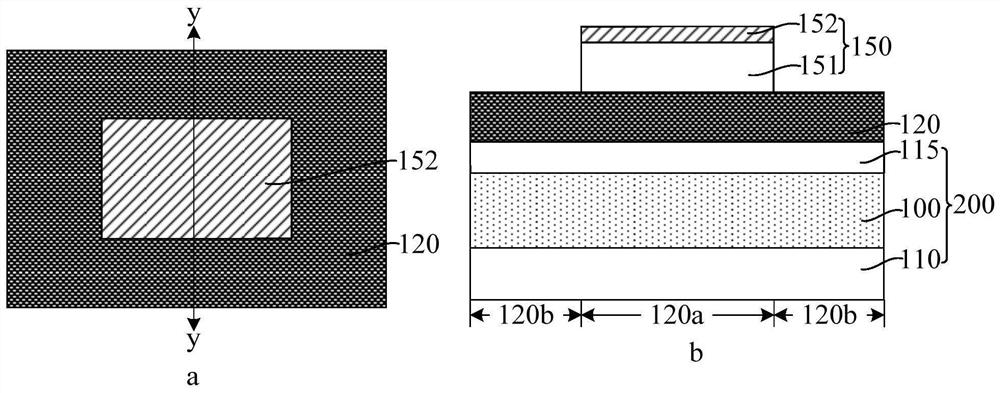

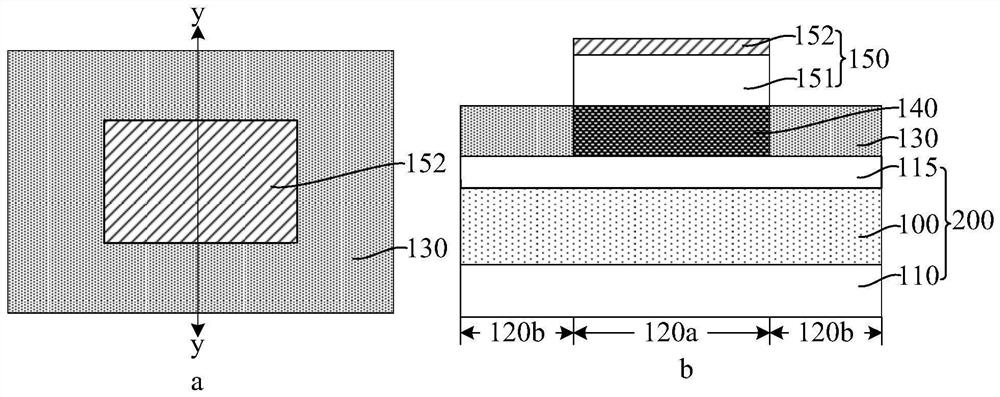

[0039] It can be known from the background art that how to improve the matching degree between the pattern formed on the wafer and the target pattern becomes a challenge in the case of shrinking technology nodes.

[0040] In order to solve the above technical problem, an embodiment of the present invention provides a method for forming a semiconductor structure, performing ion doping on the core material layer in the second region to form an anti-etching layer in the second region and a layer in the second region. The core layer of the first region, in the step of forming the first trench, in the second direction, part of the core material layer of the first region remains on both sides of the first trench, that is, In other words, the first region spans the first groove along the second direction, and then forms sidewalls on the sidewalls of the first groove, so that the sidewalls enclose the first groove, and after removing the core layer In the step, the formed second groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com