Method for shortening analytic period of mfg. process

A technology of photoresist layer and material layer, which is applied in the field of shortening the analysis cycle of the process, can solve the problems that the process width of semiconductor elements cannot be reduced, and the efficiency of the process operation is limited, and the flexibility of the process operation is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

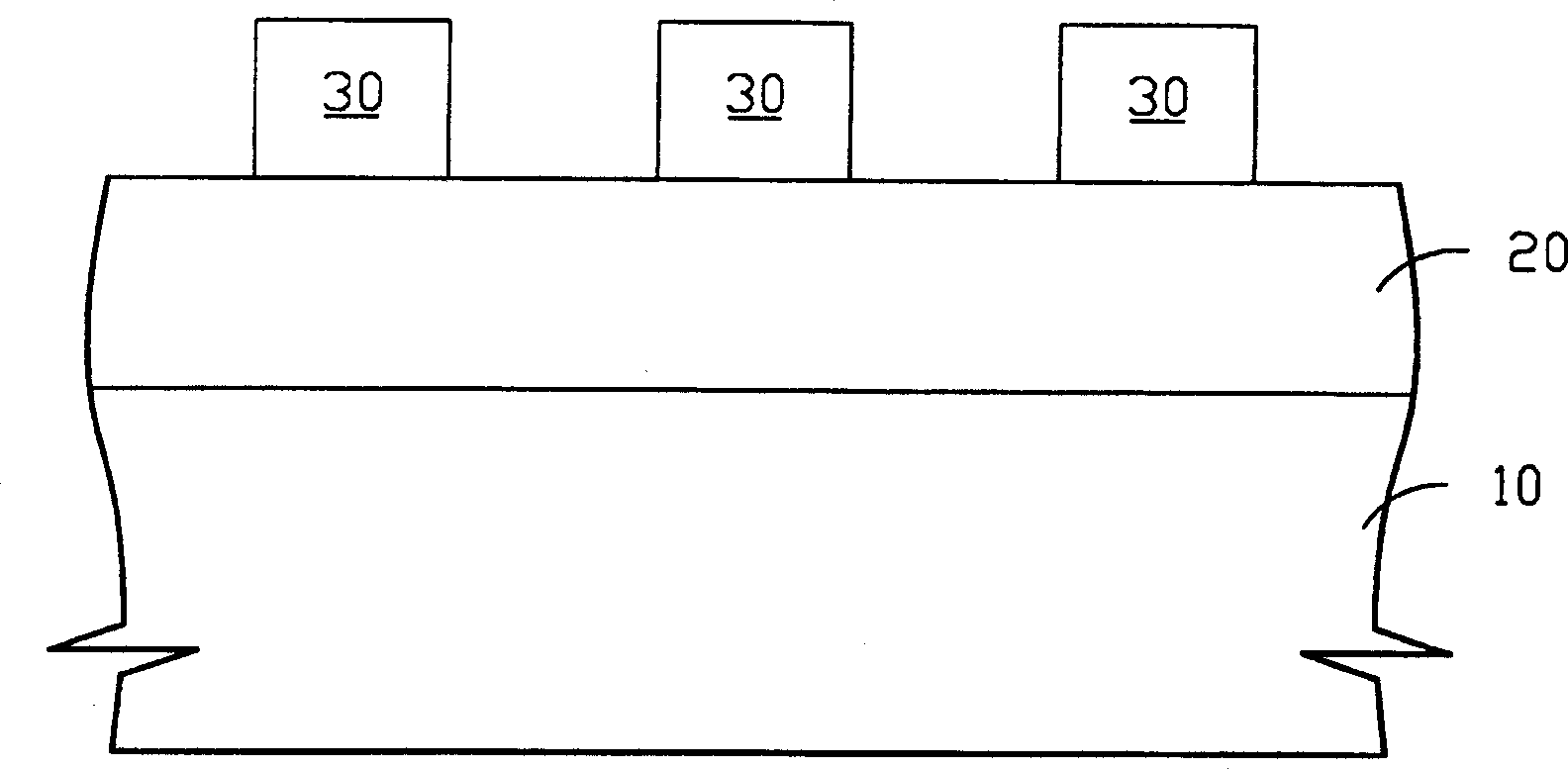

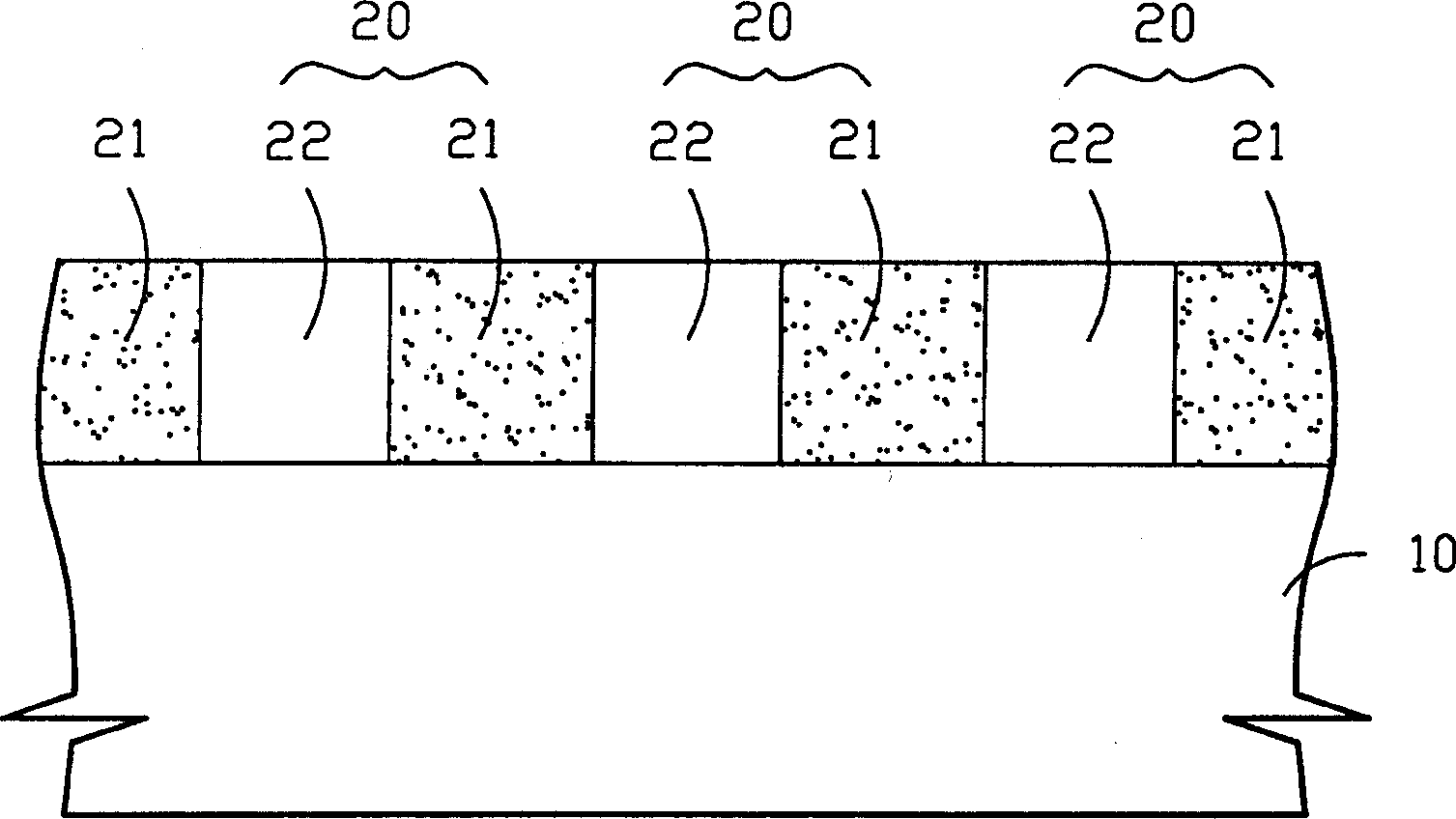

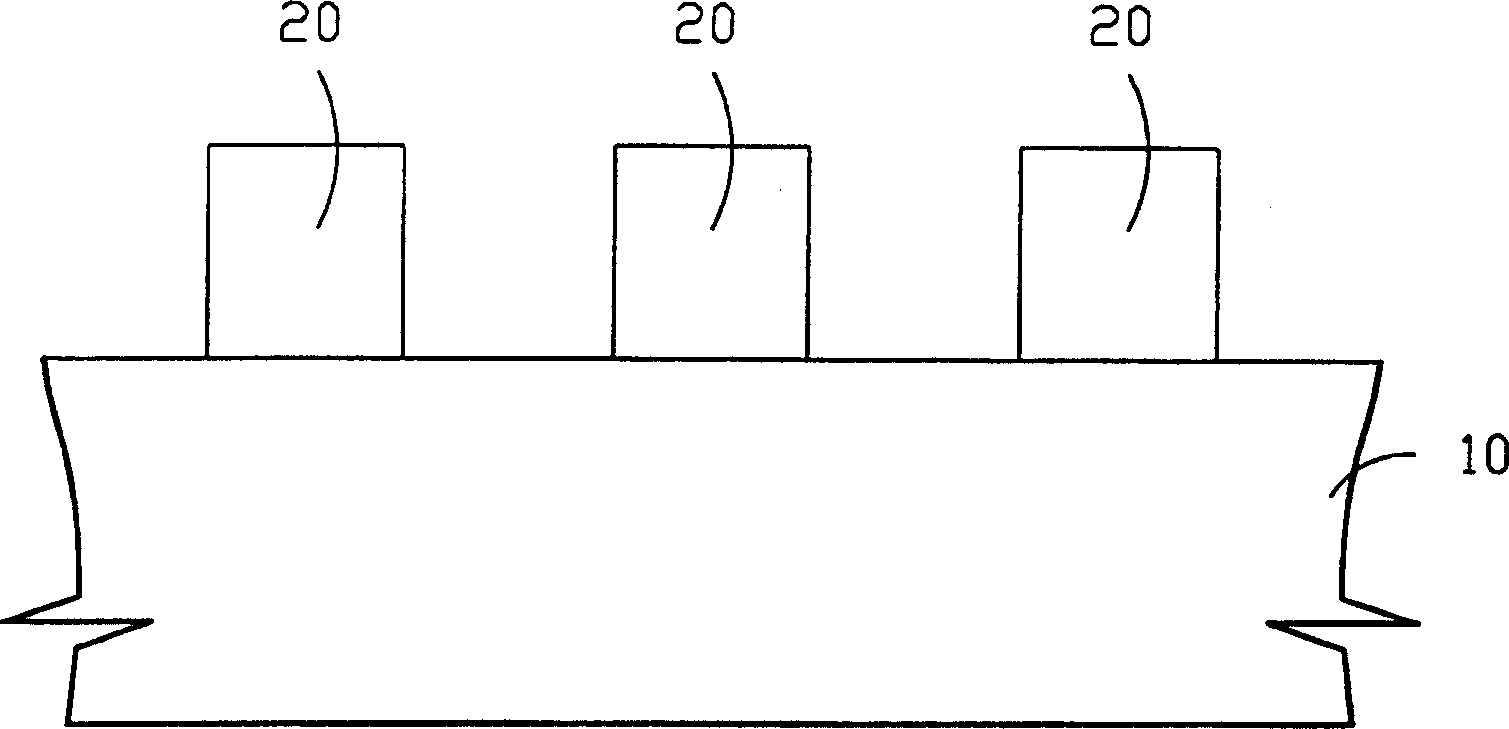

[0029] refer to Figure 4 As shown, this is a schematic diagram of forming a photoresist layer on a part of the substrate. Firstly, a wafer is provided, and the wafer includes a substrate 100 . Next, a first photoresist layer 200 is formed on the substrate 100 . The first photoresist layer 200 can be a photoresist layer exposed by deep ultraviolet light or a photoresist layer exposed by i-line light, but this does not limit the scope of the present invention. Usually, the first photoresist layer 200 is made of a photoresist layer exposed by deep ultraviolet light. Next, a photomask is used to carry out a first photolithography process, so as to completely transfer the pattern on the photomask to the first photoresist layer 200 . Next, part of the first photoresist layer 200 is removed to form the first photoresist layer 200 on part of the substrate 100 . In the lithography process, the light source used by the exposure machine can be any type of light source, such as off-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com