Control system and method for energy-saving optimizing operation of vacuum belt dehydrator

A vacuum belt, optimized operation technology, applied in chemical instruments and methods, separation methods, moving filter element filters, etc. Reduced energy consumption, improved reliability, optimized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

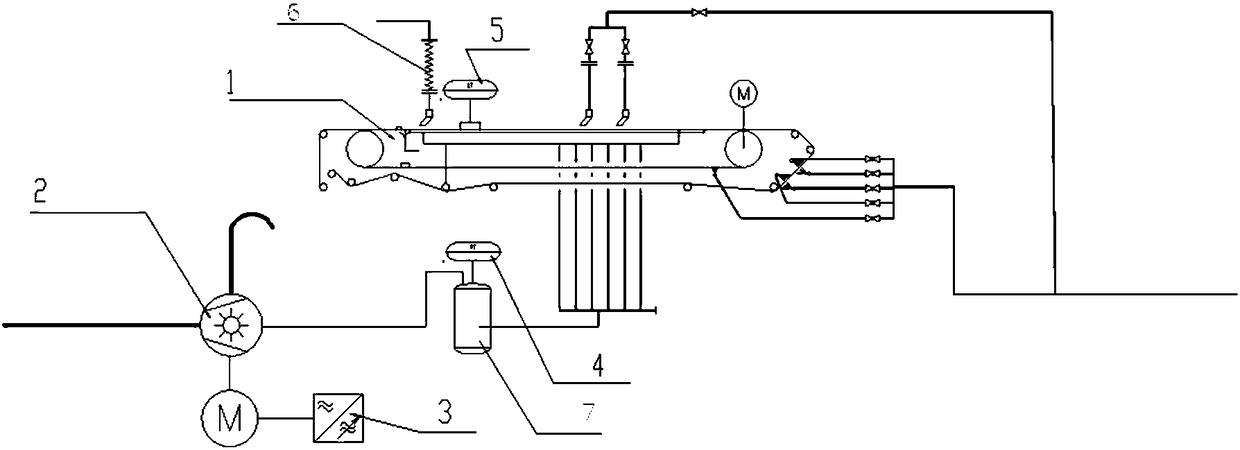

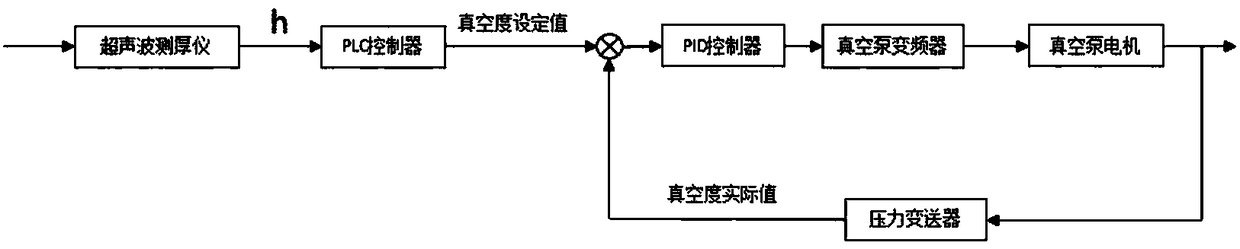

[0028] Such as figure 1 As shown, a control system for energy-saving and optimal operation of a vacuum belt dehydrator described in an embodiment of the present invention, the system includes:

[0029] Vacuum belt dehydrator 1, a vacuum chamber is set under the dehydration belt;

[0030] Vacuum pump 2, which is connected with the vacuum chamber;

[0031] The frequency converter 3 is connected to the vacuum pump motor of the vacuum pump 2 and is electrically connected to the DCS system;

[0032] A pressure transmitter 4, which is arranged on the gas-liquid separator 7 between the vacuum pump 2 and the vacuum chamber, and is electrically connected to the DCS system;

[0033] The ultrasonic measuring instrument 5 is arranged at the outlet of the cyclone 6 of the vacuum belt dehydrator 1, and is electrically connected to the DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com