Anti-corrosive spraying device for inner wall of wind power generation tower

An anti-corrosion spraying and tower technology, which is used in wind power generation, spray devices, wind turbines, etc., can solve the problems of dark light on the wall, hidden dangers, low efficiency, etc., to ensure personal safety, isolation and contact, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

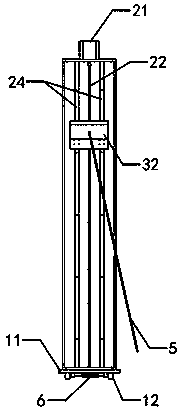

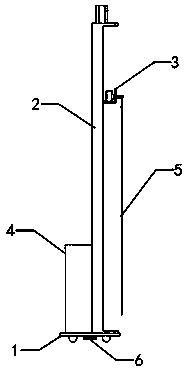

[0022] Such as figure 1 As shown, an anticorrosive spraying device for the inner wall of a wind power tower barrel includes a horizontal moving device 1, a vertical lifting device 2 and a spray rod 5 connected to each other, and the horizontal moving device 1 is vertically connected to the vertical lifting device 2 , The spray bar 5 is connected to the vertical lifting device 2 through a rotating device 3; the horizontal moving device 1, the vertical lifting device 2 and the rotating device 3 communicate through a control cabinet 4, and the control cabinet 4 is installed On the horizontal moving device 1; an electromagnet 6 is installed at the center of the bottom of the horizontal moving device 1.

[0023] Specifically, in this embodiment, the horizontal moving device 1 is mainly used to drive the spray bar 5 for horizontal linear movement, and the vertical lifting device 2 is mainly used to adjust the position of the spray bar 5 inside the tower. The connection point of the rot...

Embodiment 2

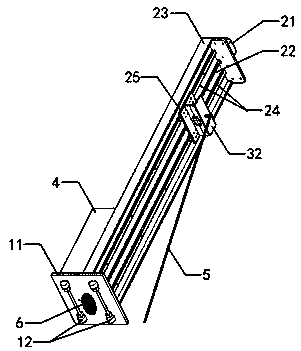

[0026] In this embodiment, the vertical lifting device 2 includes a supporting frame 23 that is vertically fixed to the horizontal moving device 1, and a screw 22 perpendicular to the horizontal moving device 1 is embedded on the supporting frame 23, so The screw 22 is driven by a screw motor 21 fixed on the top of the support frame 23; a sliding block 25 matching the screw 22 is sleeved on the screw 22, and both sides of the sliding block 25 The sides are respectively provided with sliding grooves (not marked in the figure), and the sliding grooves are matched with sliding rails 24 arranged on the supporting frame 23 and parallel to the screw 22; the rotating device 3 and the sliding Block 25 is fixed.

[0027] Specifically, the bottom center of the slider 25 is provided with a screw groove that matches the screw 22, and both sides of the slider 25 are matched with the sliding rails 24 provided on the support frame 23 through the sliding grooves. This structure can more stably ...

Embodiment 3

[0029] As a further improvement of Embodiment 2, the vertical lifting device 2 includes a first support frame vertically fixed to the horizontal moving device 1, and a second support frame perpendicular to the horizontal moving device is embedded on the first support frame. A screw rod, the first screw rod is driven by a first screw motor fixed on the top of the first support frame; the first screw rod is sheathed with a first screw rod matching the first screw rod Sliding block, the first sliding block is provided with first sliding grooves on both sides of the first sliding block respectively, and the first sliding grooves are arranged on the first support frame and parallel to the first screw rod. The sliding rail is matched; it also includes a second support frame parallel to the first support frame and perpendicular to the horizontal moving device. The bottom end of the second support frame is fixed to the first sliding block, and the The support frame is embedded with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com