Vacuum pipeline magnetic levitation train braking system and method

A technology of magnetic levitation trains and vacuum pipelines, applied in railway braking systems, tunnel systems, pneumatic brakes, etc., can solve problems such as temperature rise of braking devices, failure to achieve expected results, and decline in braking efficiency, achieving high reliability , simple structure and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

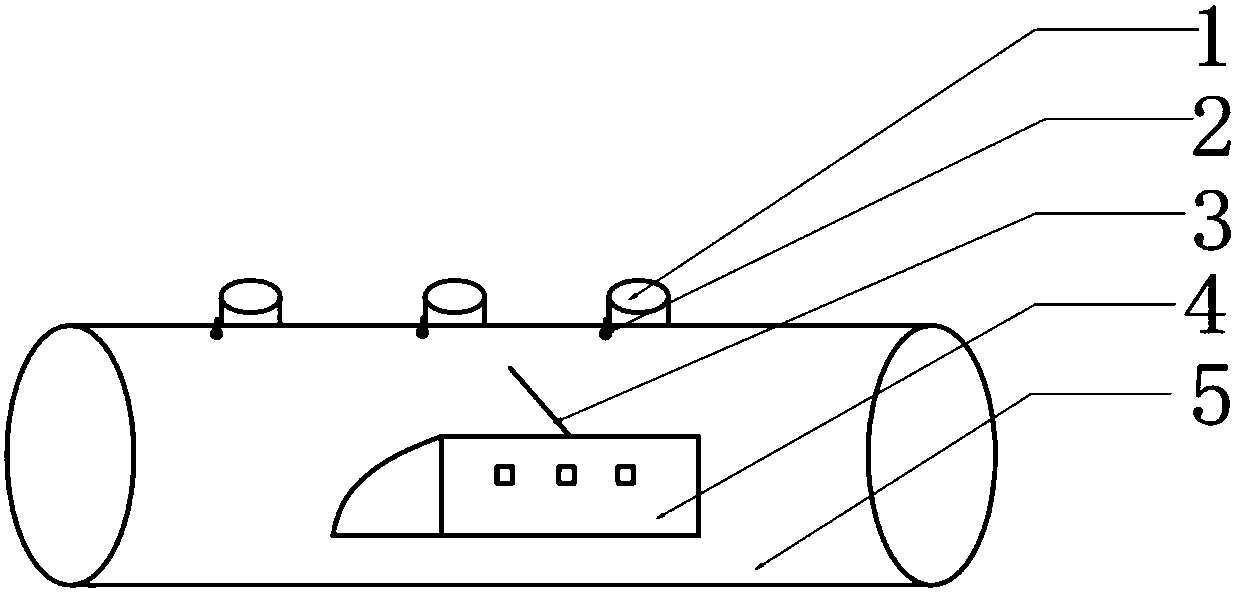

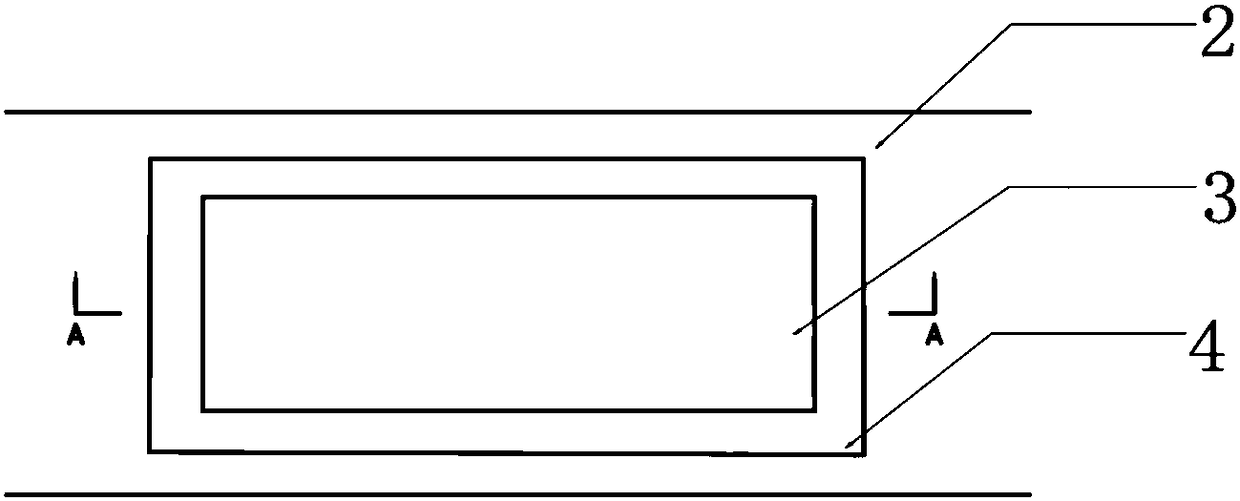

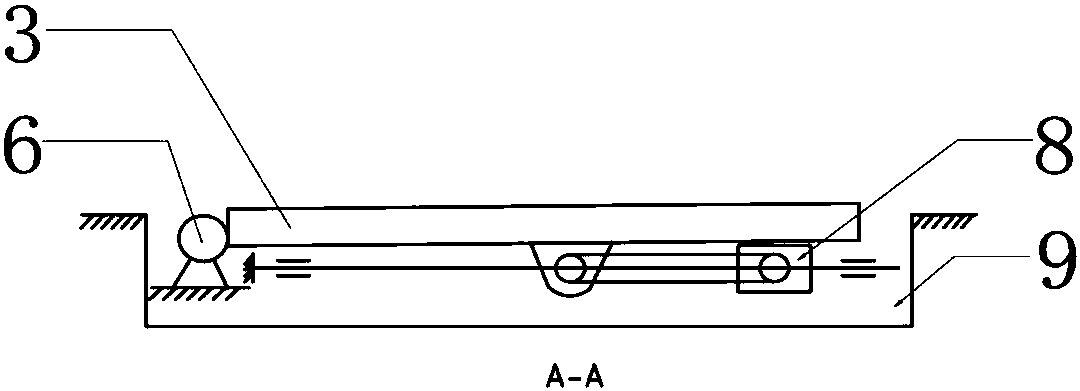

[0025] Such as Figure 1~Figure 4 Shown is the braking system of a vacuum pipeline magnetic levitation train implemented according to the present invention, which at least includes: an air charging port 1, a pressure sensor 2, a brake wing plate 3, a train compartment 4, a vacuum pipeline 5, a hinge 6, a connecting rod 7, and a screw rod Slider 8, compartment top 9; Described inflation port 1 is arranged on the vacuum pipeline 5, and an inflation port 1 is set at intervals, and a gas one-way valve and pressure sensor 2 are arranged at the inflation port 1 place, and each The top 9 of the compartment is provided with a brake wing 3, the middle of the lower surface of the brake wing 3 is connected with a hinge 6 and a connecting rod 7, the other end of the connecting rod 7 is connected with the slider of the screw slider 8, and the brake wing T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com