Biogas production equipment using recycled cattle and sheep manure of animal husbandry

A kind of production equipment and animal husbandry technology, which is applied in the field of biogas production equipment after recycling cattle and sheep manure in animal husbandry, which can solve the problems of time-consuming and labor-intensive manure handling and difficult to dissipate the odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

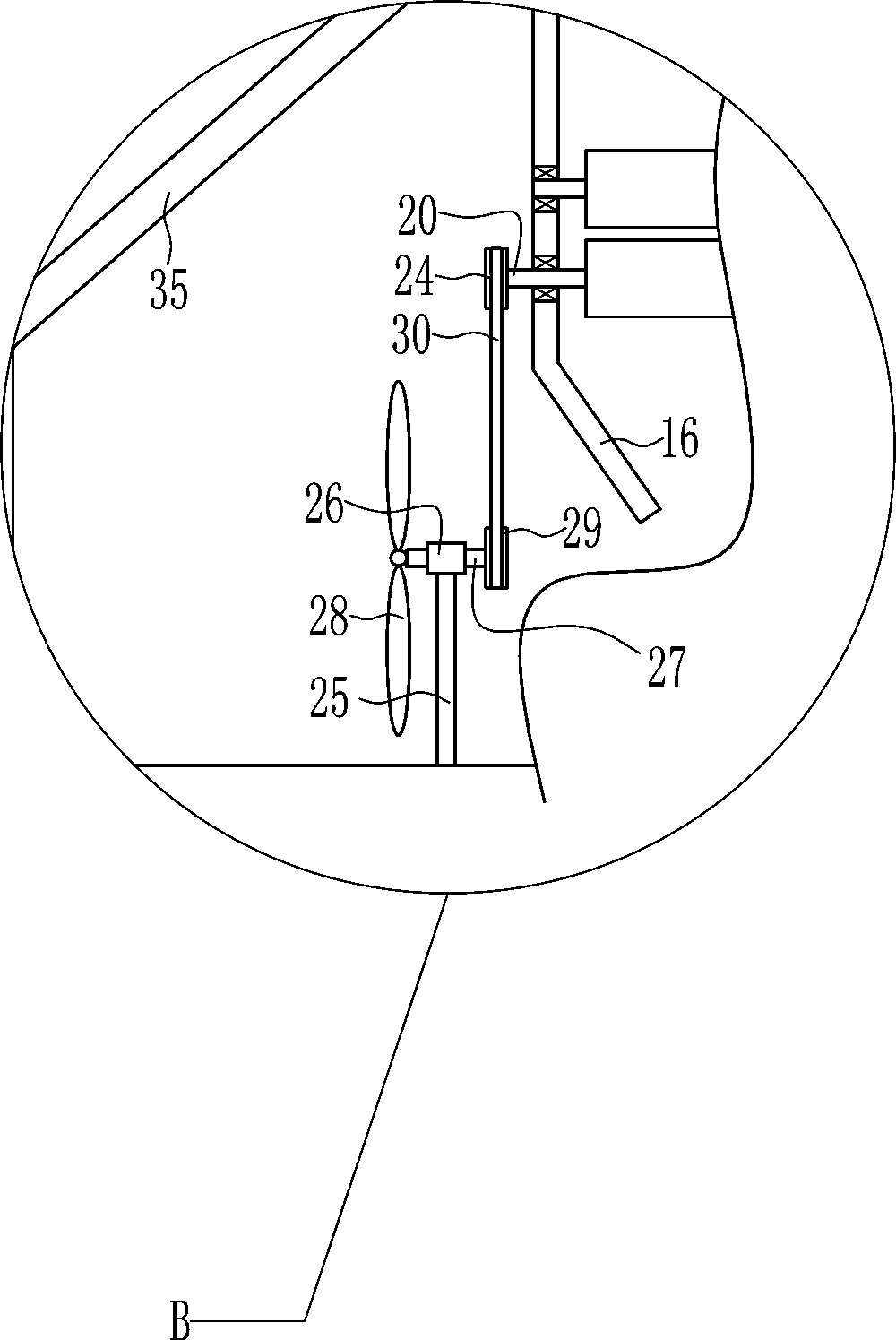

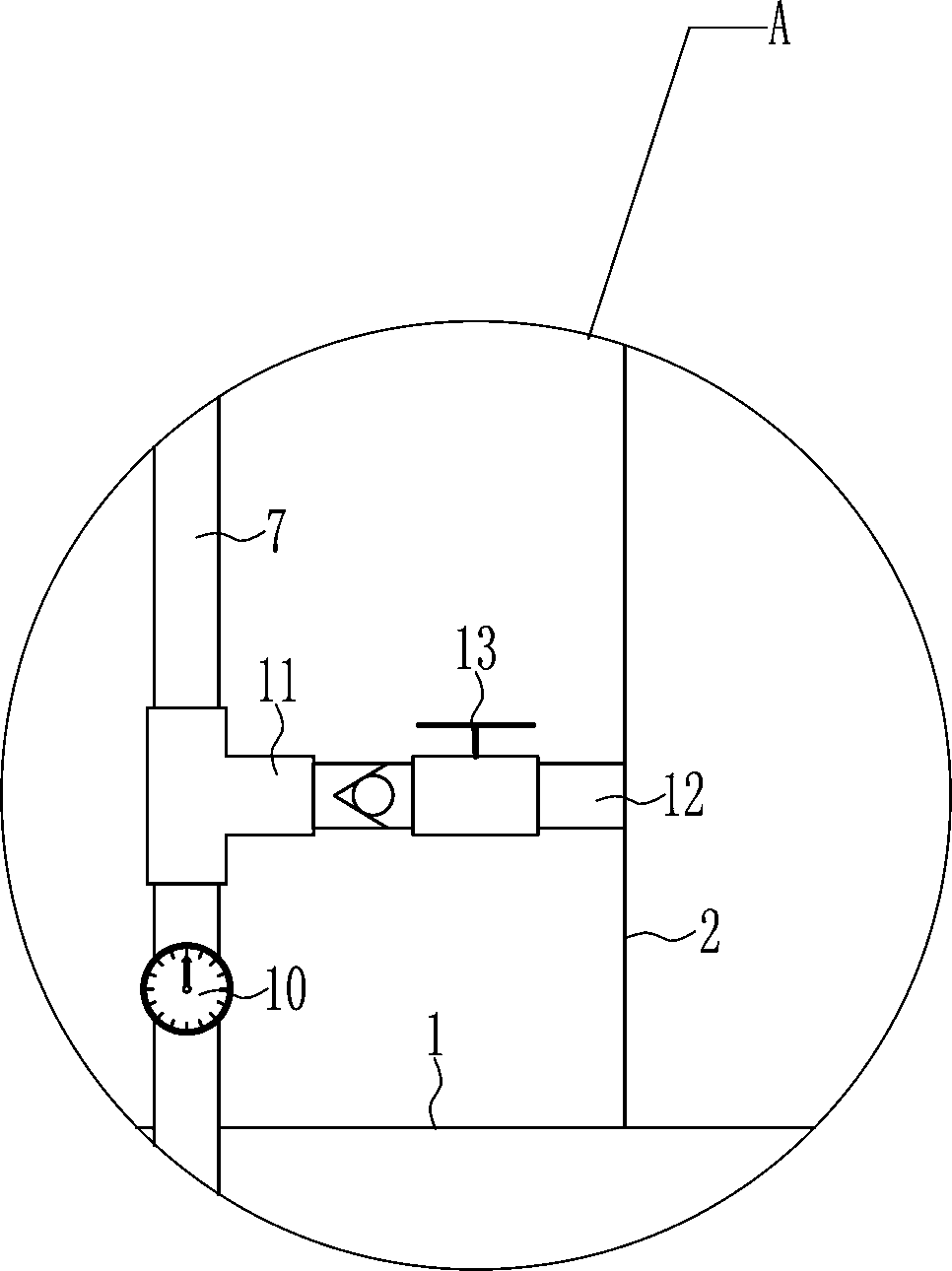

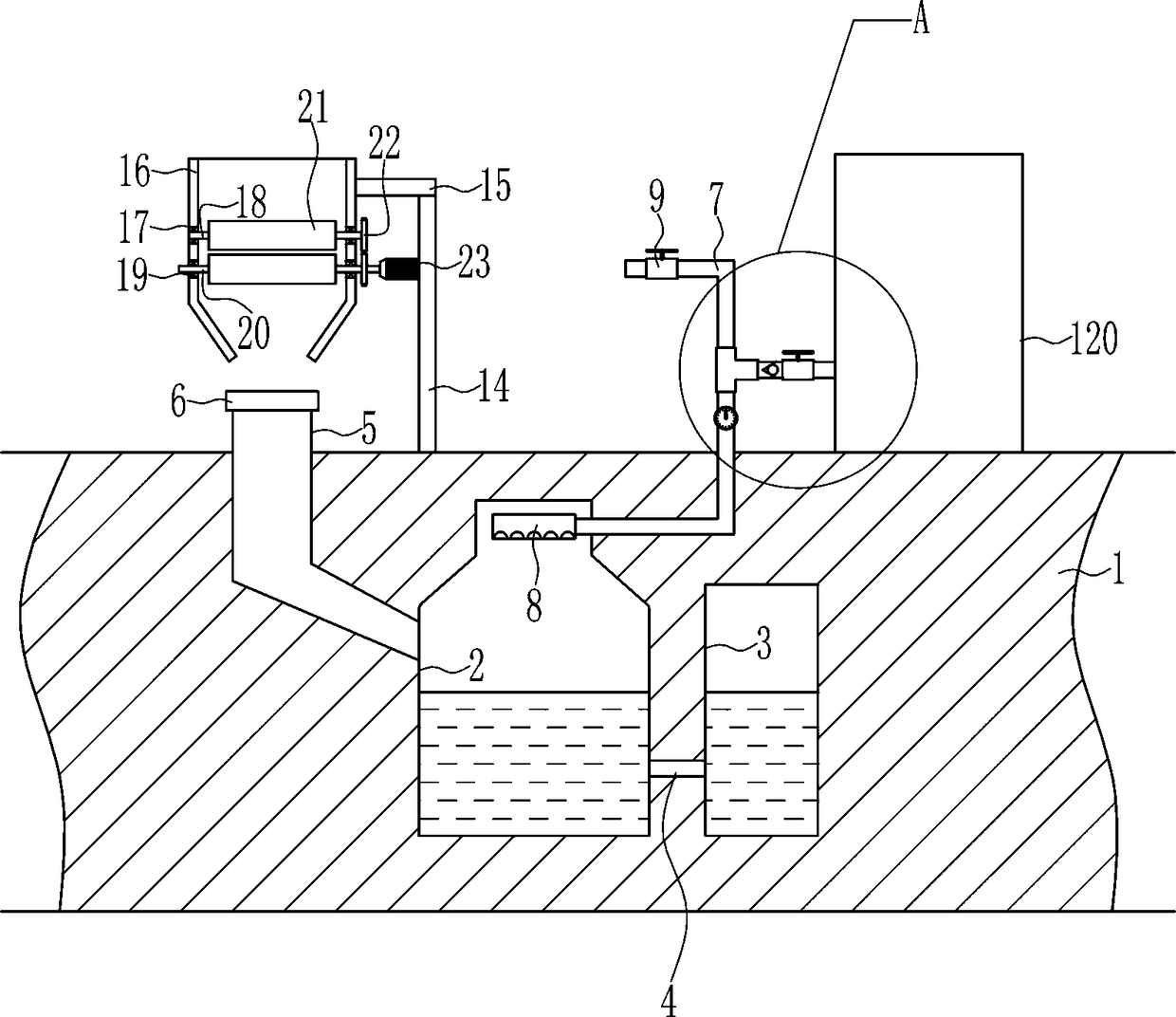

[0029] A kind of biogas production equipment after recycling cattle and sheep manure in animal husbandry, such as Figure 1-6 As shown, it includes a biogas digester 2, a water pressure room 3, a communication pipe 4, a feed frame 5, a sealing cover plate 6, an exhaust pipe 7, a hollow pipe 8, a first valve 9, a pressure gauge 10, an adapter 11, The first one-way pipe 12, the gas storage tank 120, the second valve 13, the first fixed plate 14, the second fixed plate 15, the grinding frame 16, the first bearing seat 17, the first rotating shaft 18, the second bearing seat 19, The second rotating shaft 20, grinding rod 21, transmission gear 22 and motor 23, a biogas tank 2 is dug in the ground 1, and a water pressure room 3 is dug in the ground 1 on the right side of the biogas tank 2, and the lower part of the water pressure room 3 is connected with the biogas tank 2 The lower part is connected with a communication pipeline 4, and the upper left side of the biogas digester 2 is...

Embodiment 2

[0031] A kind of biogas production equipment after recycling cattle and sheep manure in animal husbandry, such as Figure 1-6 As shown, it includes a biogas digester 2, a water pressure room 3, a communication pipe 4, a feed frame 5, a sealing cover plate 6, an exhaust pipe 7, a hollow pipe 8, a first valve 9, a pressure gauge 10, an adapter 11, The first one-way pipe 12, the gas storage tank 120, the second valve 13, the first fixed plate 14, the second fixed plate 15, the grinding frame 16, the first bearing seat 17, the first rotating shaft 18, the second bearing seat 19, The second rotating shaft 20, grinding rod 21, transmission gear 22 and motor 23, a biogas tank 2 is dug in the ground 1, and a water pressure room 3 is dug in the ground 1 on the right side of the biogas tank 2, and the lower part of the water pressure room 3 is connected with the biogas tank 2 The lower part is connected with a communication pipeline 4, and the upper left side of the biogas digester 2 is...

Embodiment 3

[0034] A kind of biogas production equipment after recycling cattle and sheep manure in animal husbandry, such as Figure 1-6 As shown, it includes a biogas digester 2, a water pressure room 3, a communication pipe 4, a feed frame 5, a sealing cover plate 6, an exhaust pipe 7, a hollow pipe 8, a first valve 9, a pressure gauge 10, an adapter 11, The first one-way pipe 12, the gas storage tank 120, the second valve 13, the first fixed plate 14, the second fixed plate 15, the grinding frame 16, the first bearing seat 17, the first rotating shaft 18, the second bearing seat 19, The second rotating shaft 20, grinding rod 21, transmission gear 22 and motor 23, a biogas tank 2 is dug in the ground 1, and a water pressure room 3 is dug in the ground 1 on the right side of the biogas tank 2, and the lower part of the water pressure room 3 is connected with the biogas tank 2 The lower part is connected with a communication pipeline 4, and the upper left side of the biogas digester 2 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap