Enzymatic hydrolysis of proteins and glycoproteins

A protein and glycoprotein technology, applied in the fields of biology and chemistry, can solve the problems of loss of protein and enzyme, time-consuming, complex enzymatic hydrolysis process, etc., and achieve the effect of fast enzymatic hydrolysis and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

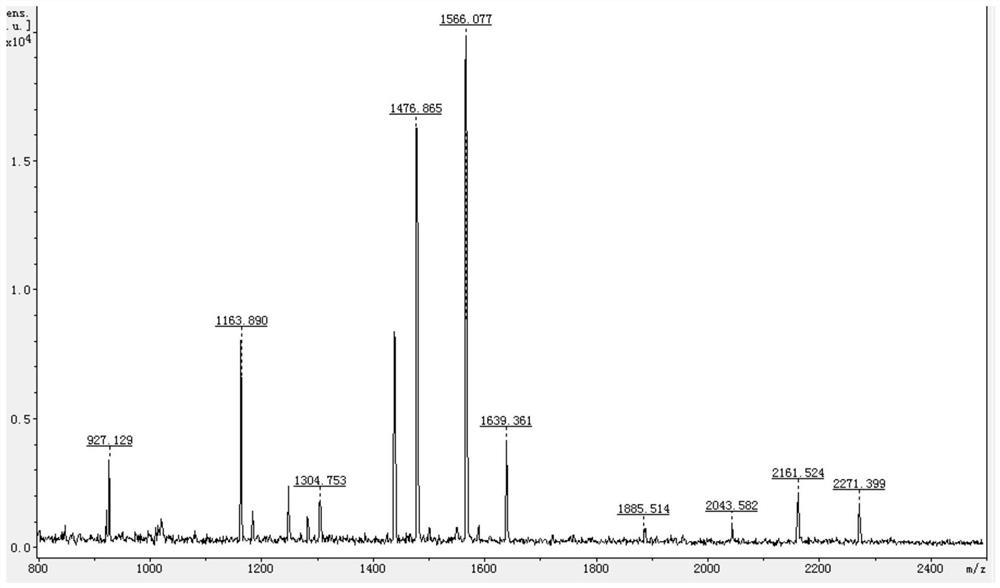

[0072] Example 1. In situ rapid proteolysis of the target plate

[0073] 1. Enzymatic hydrolysis of BSA

[0074] The BSA used is the product of Sigma-Aldrich Company.

[0075] a) NH 4 HCO 3 Concentration optimization

[0076] 1. Weigh 100mg of BSA standard protein with 100mL ddH 2 Dissolve O, put it into boiling water and boil for 10 minutes, then put it into an ice-water mixture to cool to obtain a 1 mg / mL denatured BSA solution; use deionized water to dissolve Tripsin to obtain a Tripsin aqueous solution with a Tripsin concentration of 100 ng / μL;

[0077] 2. Dilute 1 mg / mL denatured BSA solution with deionized water to obtain a denatured BSA solution with a BSA concentration of 100 ng / μL; 1 μL 100 ng / μL denatured BSA solution, 1 μL 100 ng / μL Tripsin aqueous solution, 1 μL NH 4 HCO 3 50mM NH 4 HCO 3 The aqueous solution and 7 μL of deionized water were quickly mixed to obtain a reaction mixture. In the reaction mixture, the concentrations of BSA and Tripsin were both ...

Embodiment 2

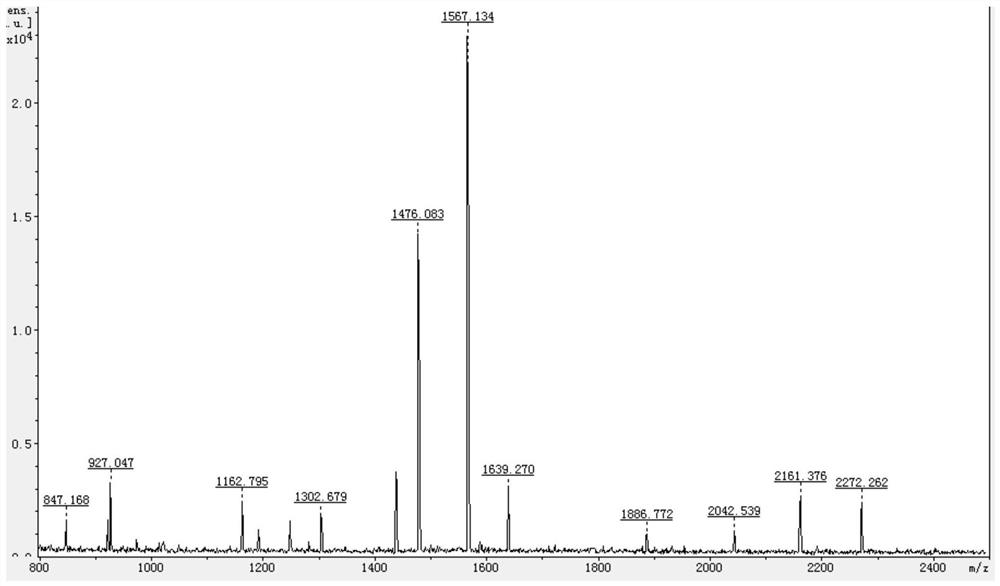

[0099] Example 2. Rapid enzymolysis of protein in liquid

[0100] 1. Weigh 200mg of BSA standard protein with 100mL ddH 2 O was dissolved, boiled in boiling water for 10 minutes, and then cooled in an ice-water mixture to obtain a 2 mg / mL denatured BSA solution;

[0101] 2. Dilute the 2 mg / mL denatured BSA solution in step 1 with deionized water to obtain a 400 ng / μL denatured BSA solution; take 25 μL of the 400 ng / μL denatured BSA solution, add 50 μL 50 mM NH to it 4 HCO 3 Aqueous solution and 25μL 200ng / μL Tripsin aqueous solution, after mixing evenly (the mass ratio of BSA and Tripsin in the reaction system obtained after mixing is 2:1, the concentration of Tripsin is 50ng / μL, NH 4 HCO 3 The concentration of 25mM) was incubated for 5 minutes at 37°C and 1200rpm (to increase the contact opportunity of protein and enzyme, using a dry thermostat (THERMO-SHAKER)) to obtain the enzymatic hydrolysis product.

[0102] 3. After the enzymatic hydrolysis in step 2, dilute the enz...

Embodiment 3

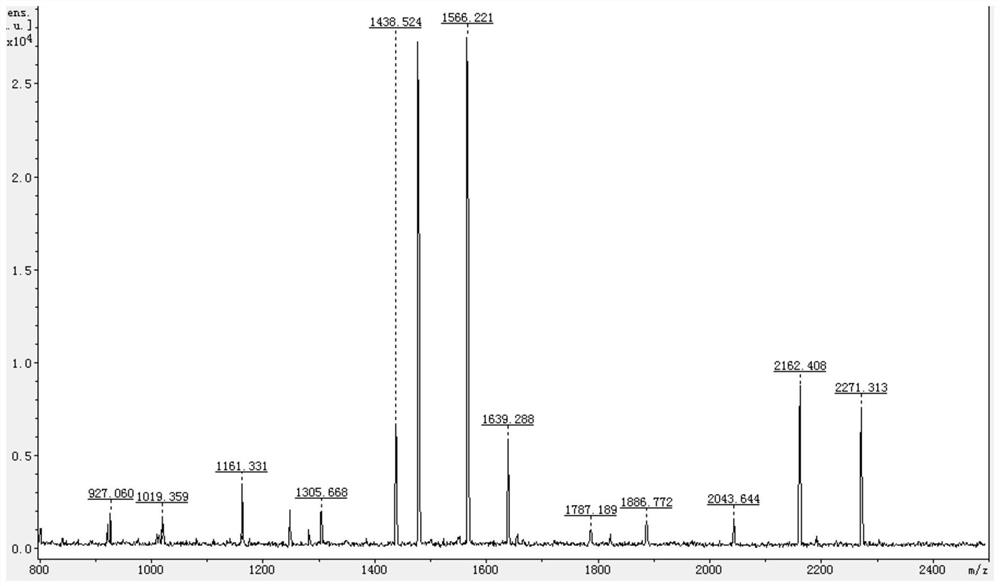

[0105] Embodiment 3, the comparison of the enzymatic hydrolysis method of the present invention and the traditional enzymatic hydrolysis method

[0106] 1. Traditional methods

[0107] 1. Weigh 200mg of BSA standard protein with 100mL ddH 2 O was dissolved, boiled in boiling water for 10 minutes, and then cooled in an ice-water mixture to obtain a 2 mg / mL denatured BSA solution.

[0108] 2. Dilute the 2 mg / mL denatured BSA solution in step 1 with deionized water to obtain a 20 ng / μL denatured BSA solution; take 25 μL of the 20 ng / μL denatured BSA solution, add 50 μL of 50 mM NH to it 4 HCO 3 Aqueous solution and 25 μL 0.4ng / μL Tripsin aqueous solution, after mixing evenly (the mass ratio of BSA and Tripsin in the reaction system obtained after mixing is 50:1, NH 4 HCO 3 The concentration of 25mM) was incubated at 37°C and 1200rpm for 12 hours to obtain the enzymatic hydrolysis product.

[0109] 3. After the enzymatic hydrolysis in step 2, take 1 μL of the enzymatic hydrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com