Drainage pipeline inner wall mortar coating machine and use method thereof

A drainage pipe and spraying machine technology, which is applied in the sewer pipe system, waterway system, water supply device, etc., can solve the problems that the internal damage of the pipe structure cannot be solved, the large-scale excavation and repair cannot be carried out, and the working environment has high requirements, so as to improve walking Efficiency, strong cohesion, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

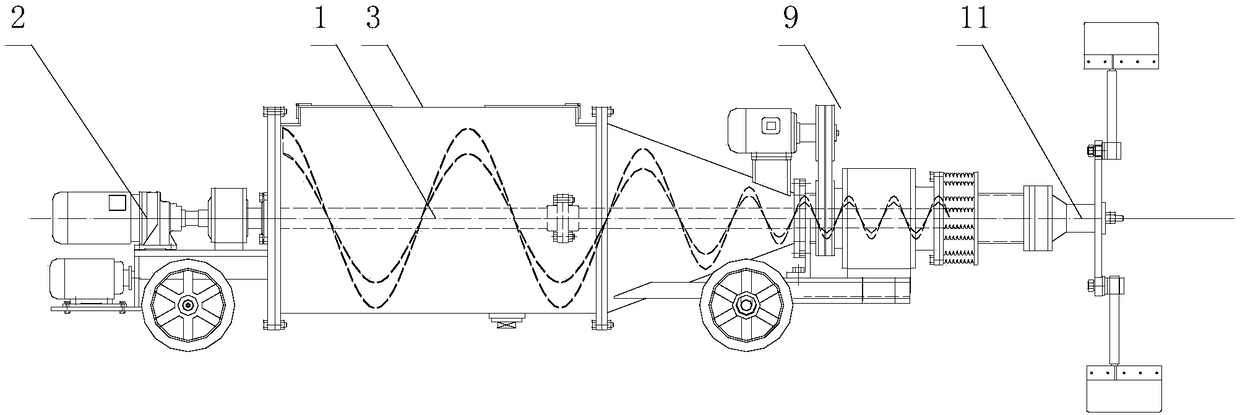

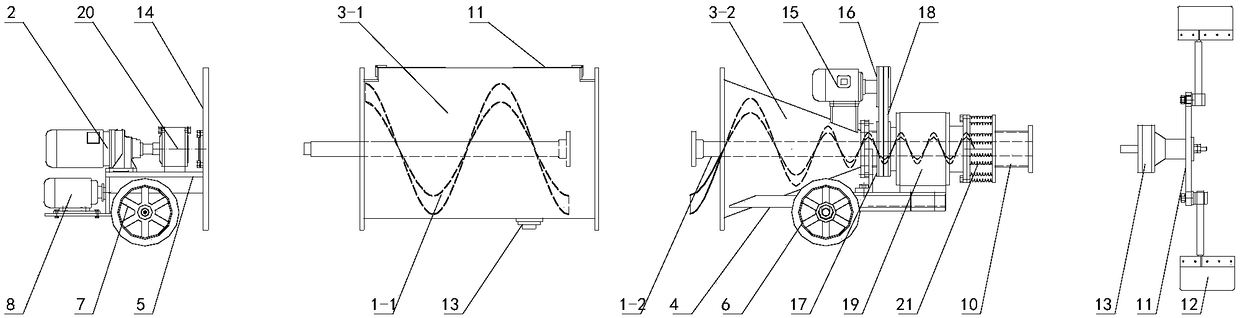

[0028] Attached below Figure 1-2 The mortar spraying machine for the inner wall of the drainage pipe of the present invention and its application method are described in detail.

[0029] A mortar spraying machine for the inner wall of a drainage pipe. The mortar spraying machine for the inner wall of a drainage pipe includes a slurry delivery power assembly, a walking power assembly, a mortar injection power assembly, and a mortar smoothing power assembly; wherein, the slurry delivery power assembly includes a slurry delivery rod 1 , the first driving part 2 for driving the rotation of the slurry delivery rod, and the slurry storage cylinder assembly 3; the slurry delivery lever is placed horizontally in the slurry storage cylinder assembly; the walking power assembly includes a front frame 4, a rear frame 5. The front wheel set 6, the rear wheel set 7 and the second driving part 8 for driving the front wheel set and the rear wheel set to walk; the front frame and the rear fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com