Drilling system with multiple circular flow channels for large-scale borehole hard rock drilling and drilling process

A multi-circulation, large-scale technology, applied in wellbore drilling drives, wellbore/well components, drilling equipment, etc., to achieve the effect of reducing demand, reducing gas injection, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

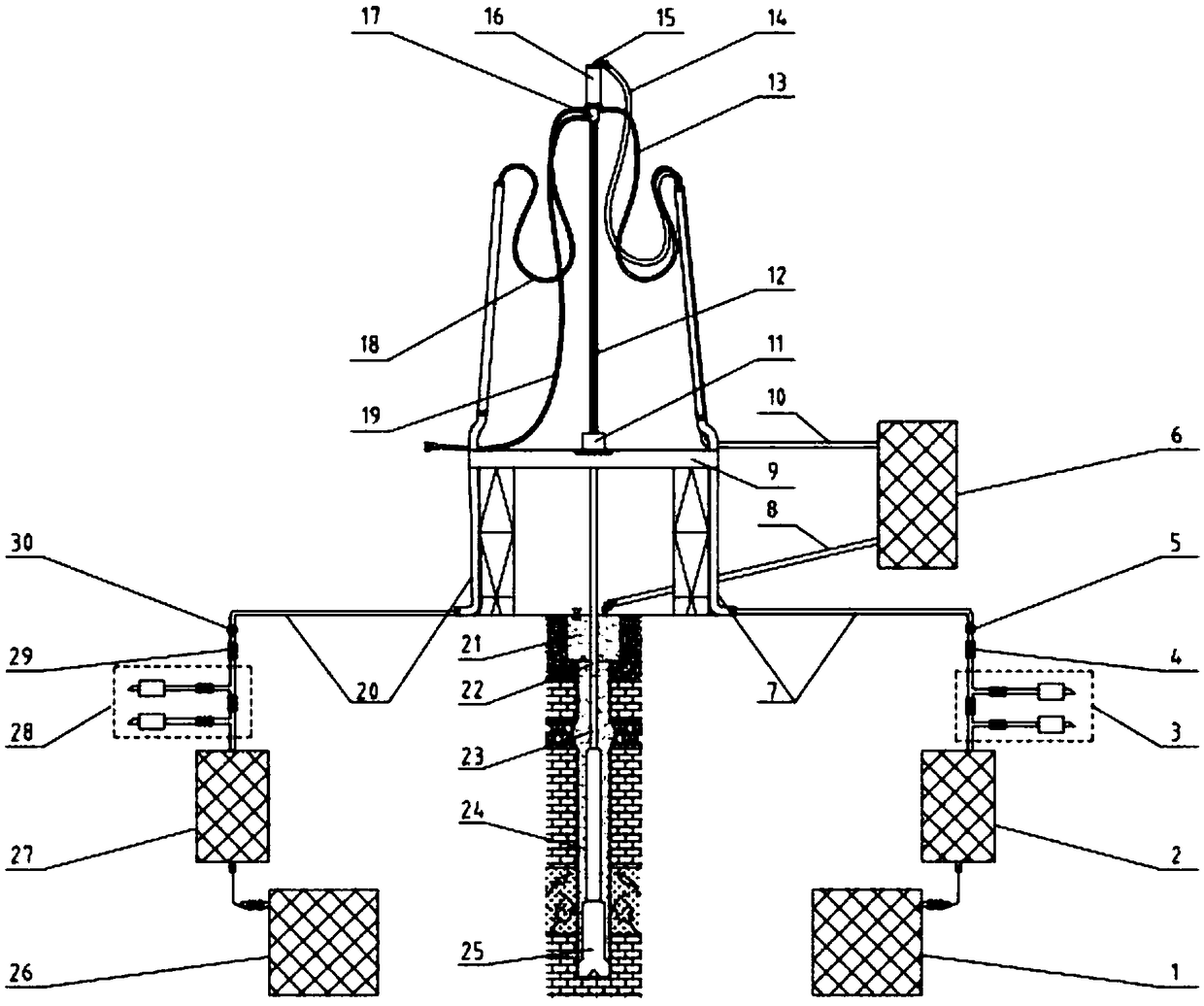

[0057] Such as figure 1 As shown, the present invention is a multi-circulation channel drilling system for large-scale hard rock drilling, including downhole air hammer surface manifold and equipment, gas lift manifold and equipment, drilling drive device, multi-circulation channel drill tools and mud circulation equipment 6, the ground manifold and equipment of the downhole air hammer and the gas lift manifold and equipment are connected to the multi-circulation channel drilling tool through the drilling drive device, and the mud circulation equipment 6 passes through the erosion-resistant gooseneck 15 and the drain The sand pipeline 14 is connected to the drilling drive.

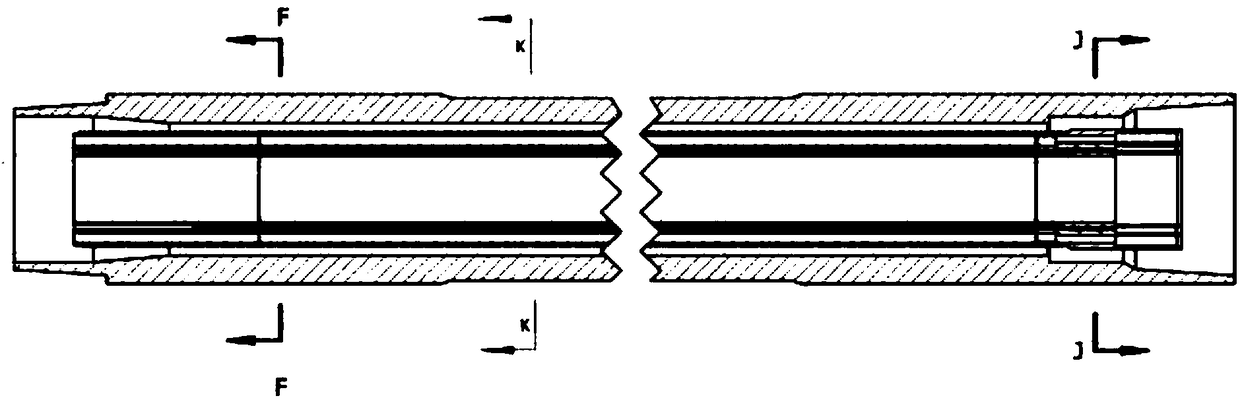

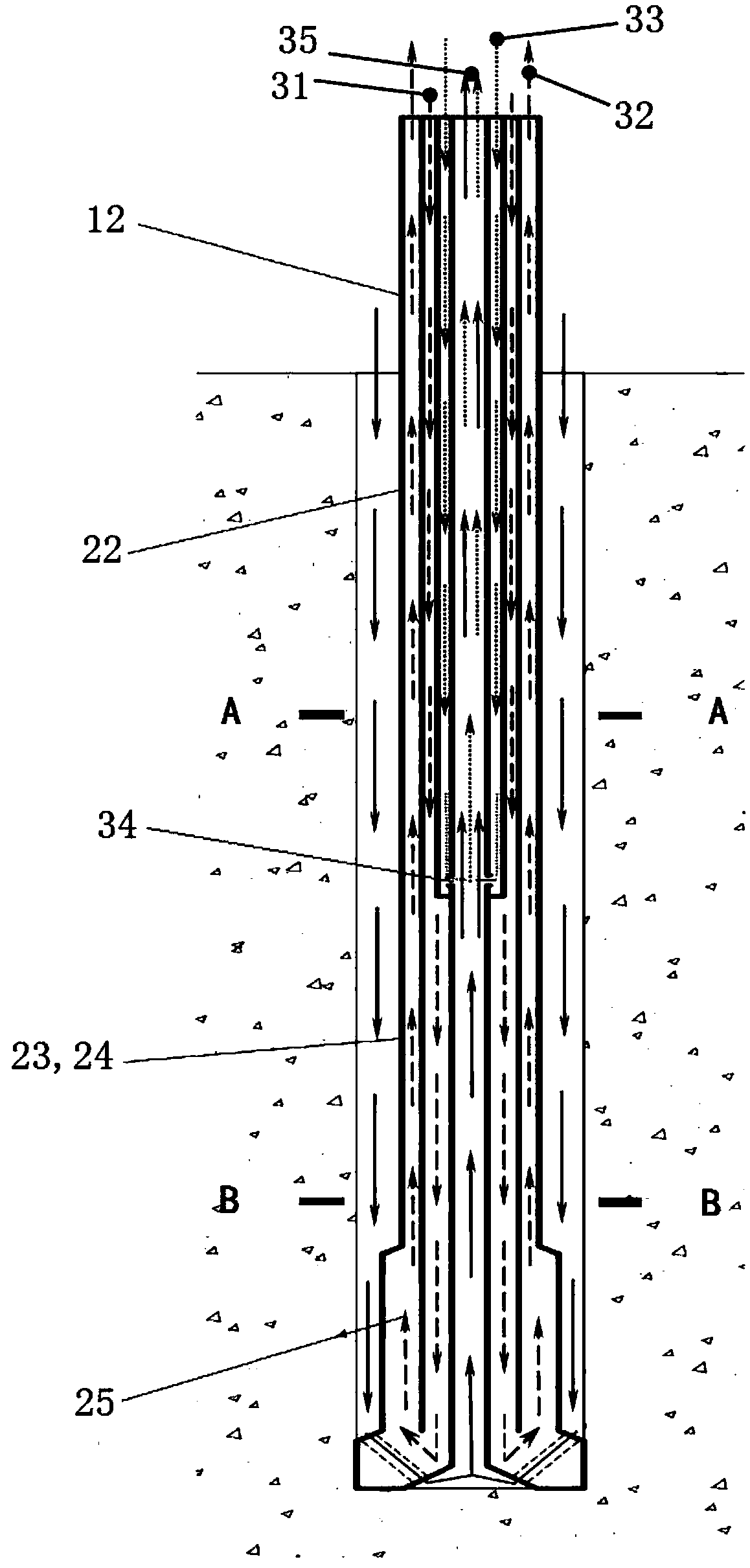

[0058] Such as Figure 2 to Figure 8 As shown, among them, the multi-circulation channel drilling tool includes the coaxial four-channel drill pipe 22, the coaxial three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com