Oil return pipe joint and installation tool thereof

A technology for installing tools and oil return pipes, used in manufacturing tools, lubricant conduit devices, hand-held tools, etc., can solve the problems of temperature rise of housing and transmission parts, sealing ring cutting, low production efficiency, etc., to improve installation Reliability and tightness, improved installation speed, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

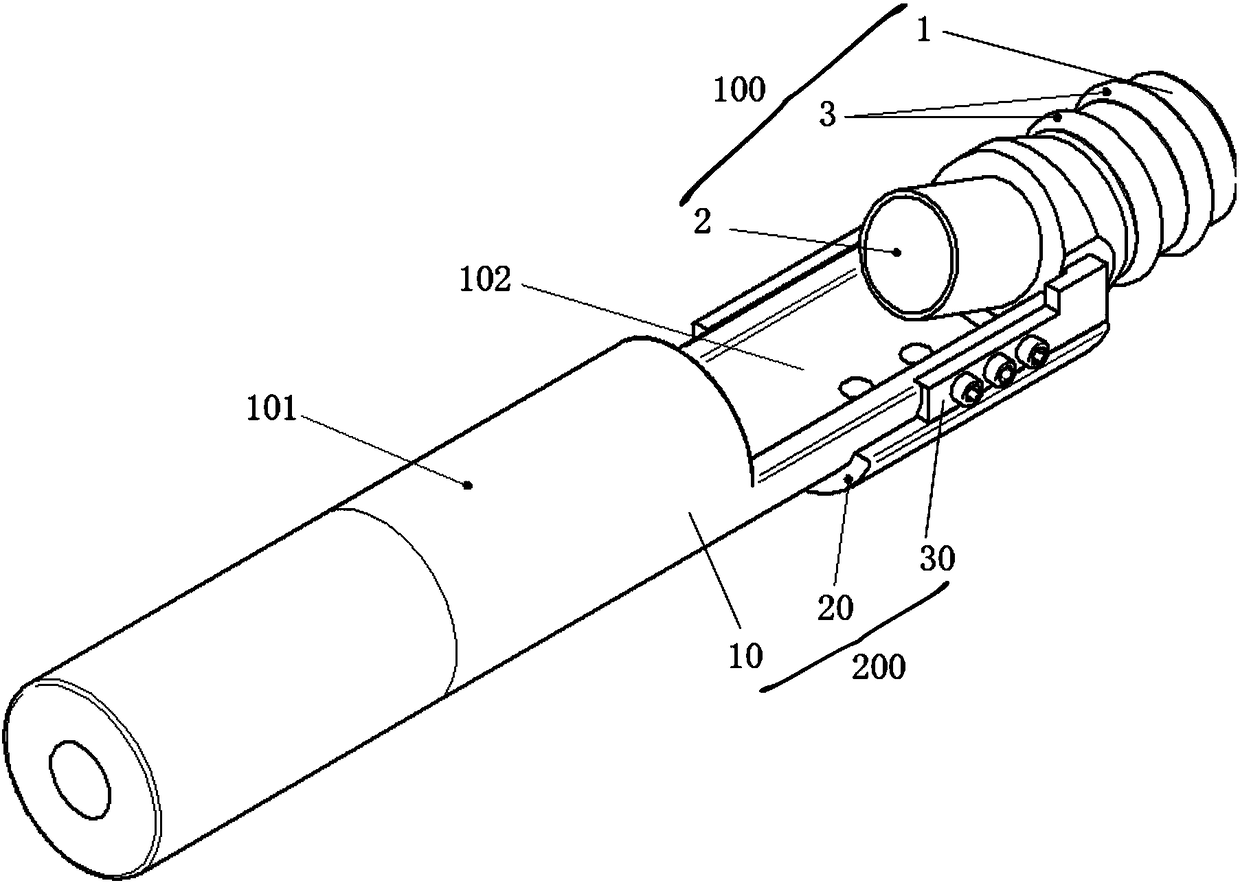

[0040] Based on the problem in the prior art that it is difficult to find the point of application of force when installing the oil return pipe joint, and the improper installation position may easily lead to oil leakage, the present invention provides an oil return pipe joint and an installation tool that can solve the above technical problems. Hereinafter, the oil return pipe joint and the installation tool will be described in detail through specific embodiments and in conjunction with corresponding drawings.

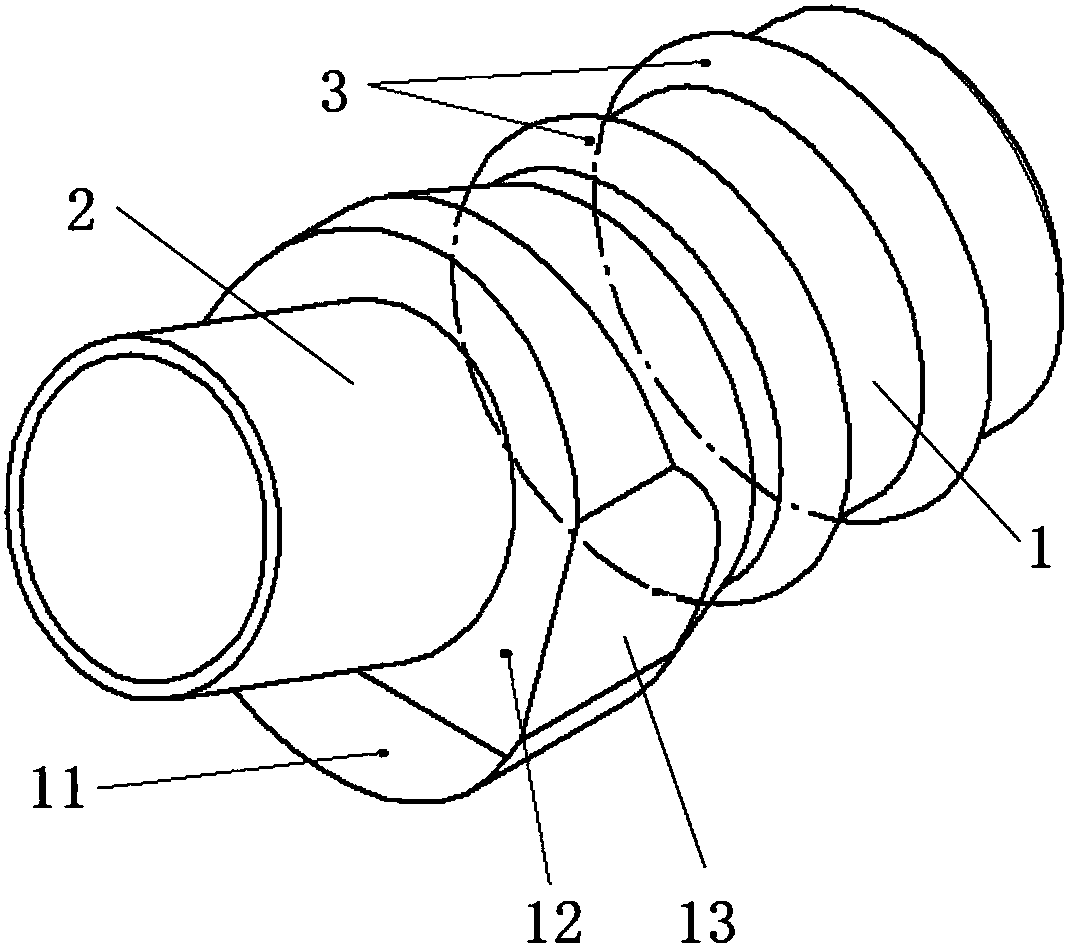

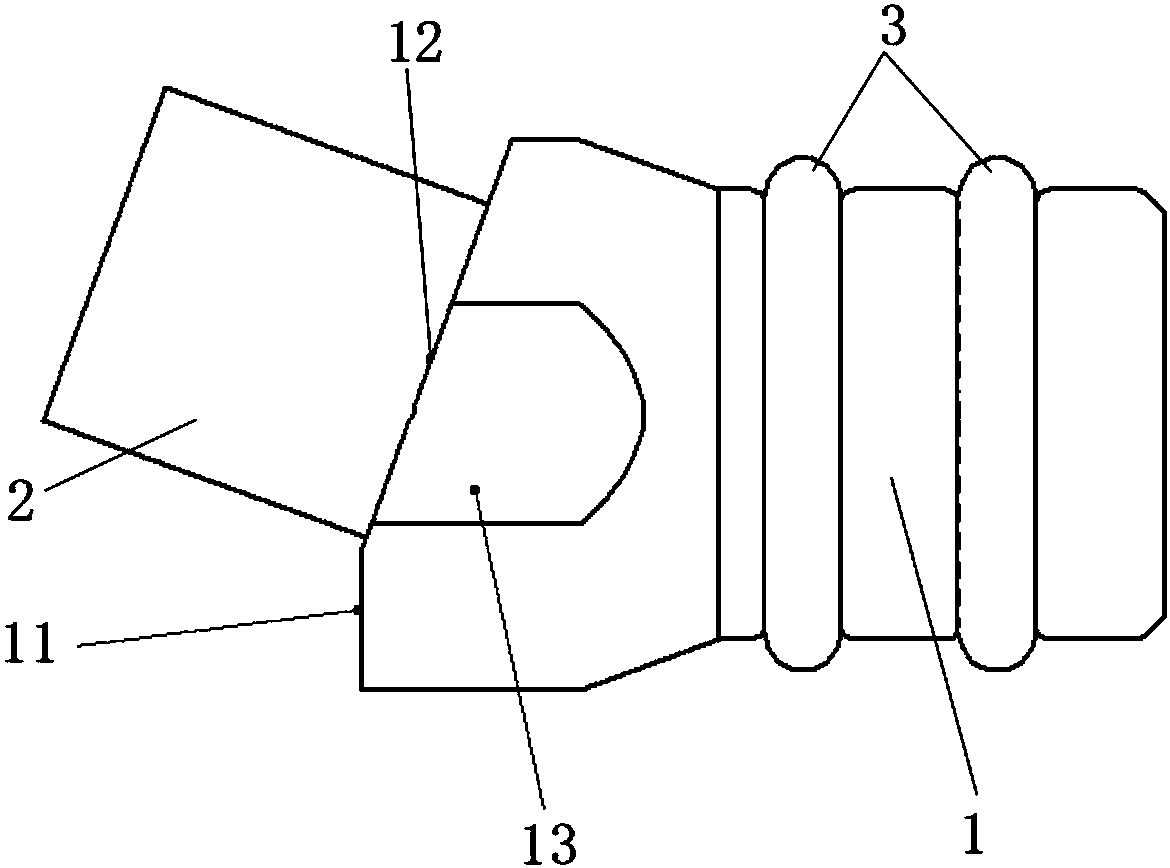

[0041] According to one aspect of the present invention, appropriate reference figure 1 and figure 2 The oil return pipe joint provided by the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com