Bearing convenient to lubricate

A bearing and outer ring technology, applied in the field of bearings that are easy to lubricate, can solve the problems that the lubricating oil cannot be dripped on the rollers by itself, cannot be dripped regularly, and the friction coefficient is large, so as to achieve a simple structure and avoid the entry of dust , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

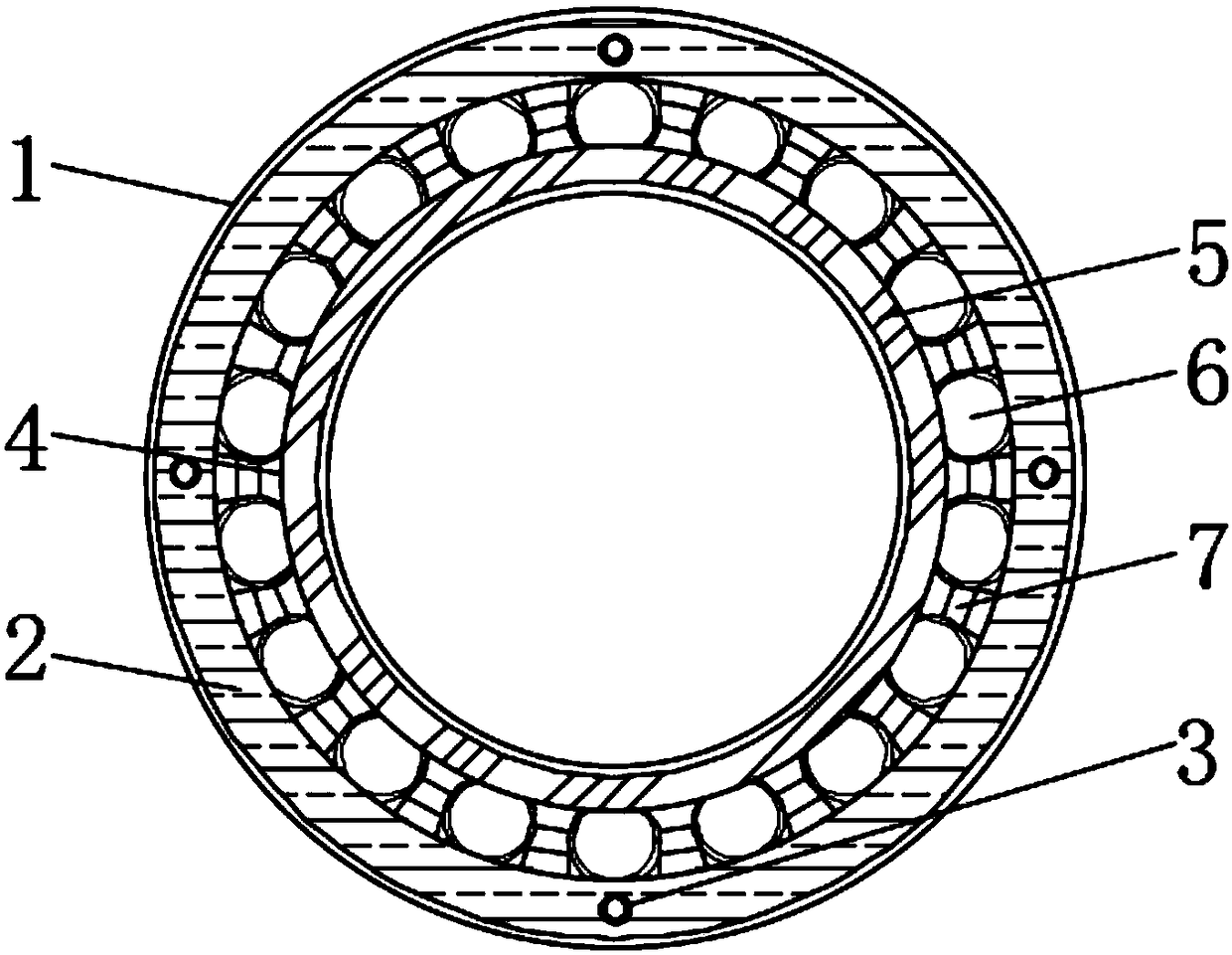

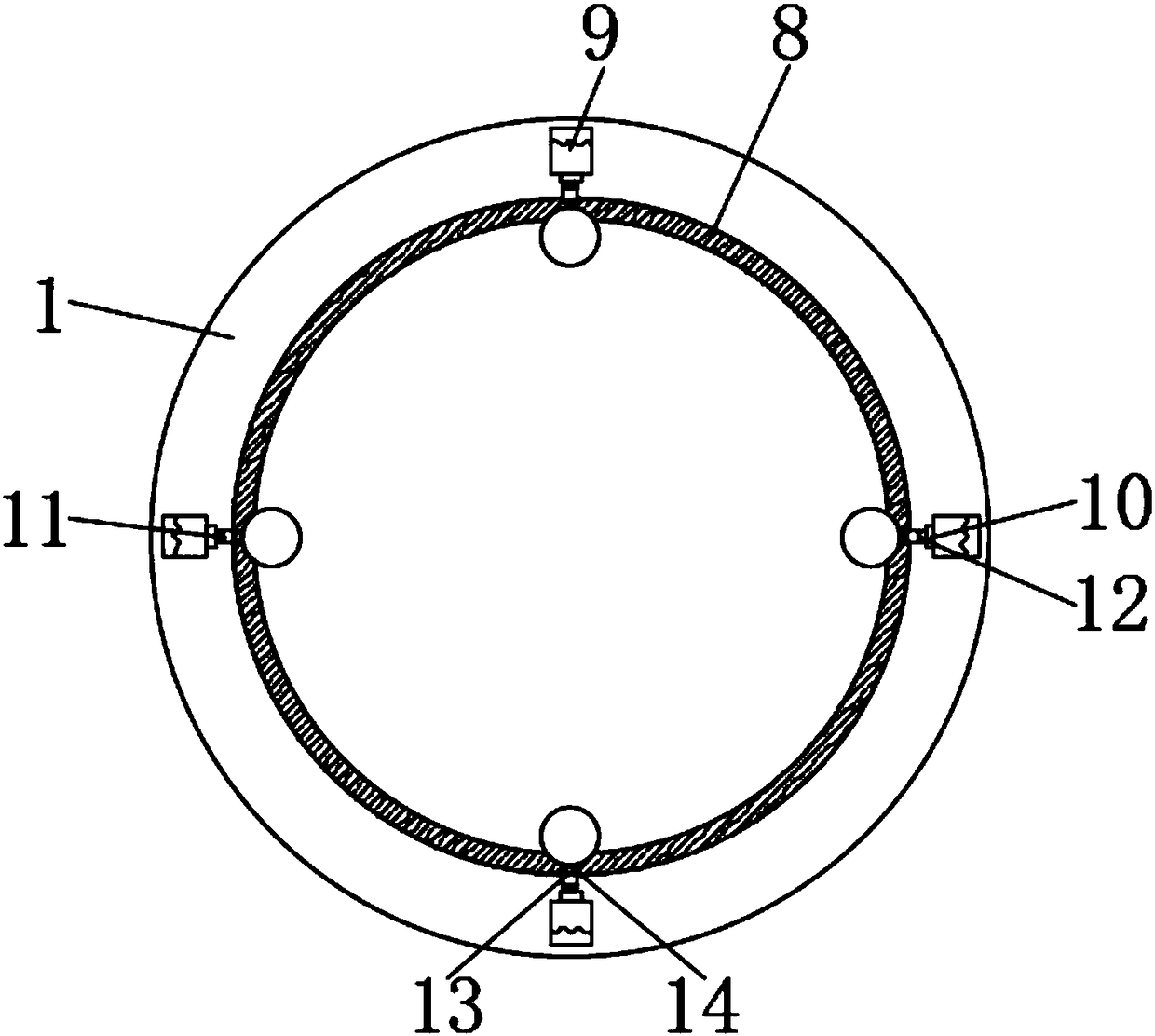

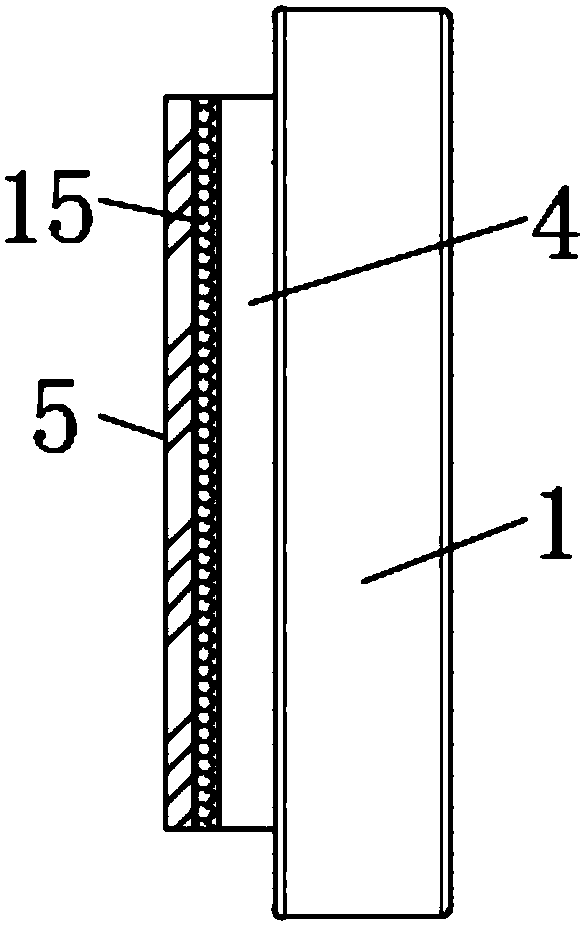

[0014] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

[0015] Depend on Figure 1-4 Given, the present invention includes an outer ring 1, an oil filling port 3 is opened on the surface of the outer ring 1, a hinge 16 is provided on one side of the oil filling port 3, a protective cover 17 is installed on the side of the hinge 16 and the oil filling port 3, and the protective cover 17 The side away from the hinge 16 is provided with a fixed buckle 18, and the inner side of the protective cover 17 is inlaid with a third sealing ring 19;

[0016] The inside of the outer ring 1 is provided with an oil storage tank 9 at the same position as the oil injection port 3, and one side of the oil storage tank 9 is provided with an oil outlet 10, and the side of the oil outlet 10 away from the oil storage tank 9 is provided with a drainage tube 11, and the drainage tube 11 A throttling valve 12 is installed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com