A non-contact high-precision length measuring system with adjustable scale

A non-contact, length measurement technology, used in measuring devices, instruments, optical devices, etc., can solve the problem of inability to intuitively calibrate the size, and achieve the effect of improving accuracy, improving production efficiency, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

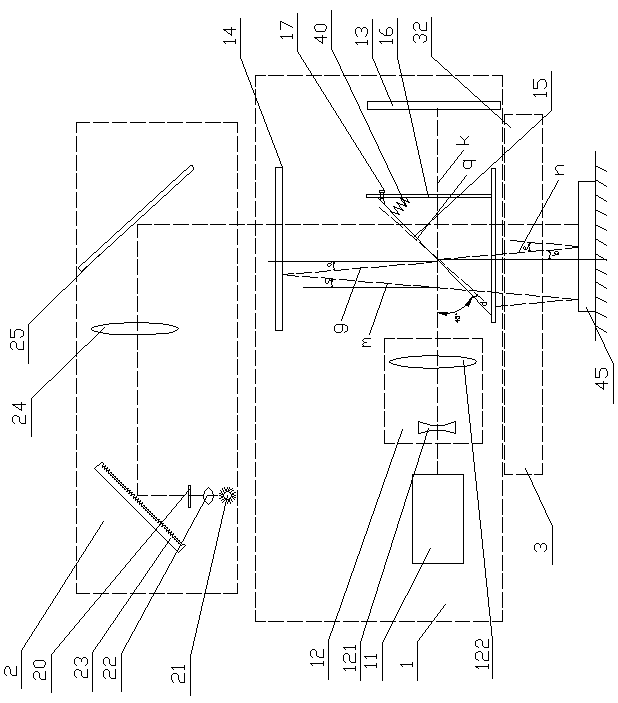

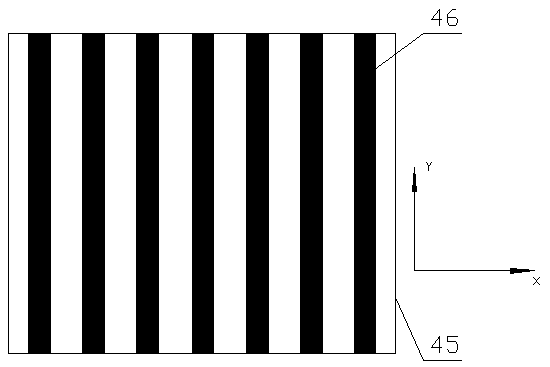

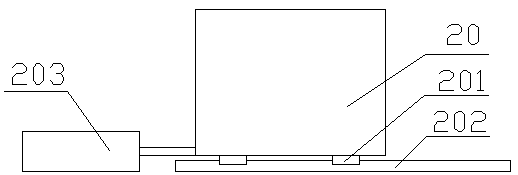

[0033] Such as figure 1 As shown in -4, the present invention includes an optical measurement projection module 1, an optical projection identification module 2 and a data collection and analysis module 3.

[0034] The optical measurement and projection module 1 includes a frequency-stabilized He-Ne laser 11, a beam expander 12, a first mirror 13, a narrow-band mirror 14, and an angle-adjustable beam splitter 15. The wavelength of the frequency-stabilized He-Ne laser 11 is 632nm, and the wavelength is stable. Beam expander 12 includes a concave lens 121 and a convex lens 122 arranged in turn on the beam exit direction of the frequency-stabilized He-Ne laser 11; the narrow-band reflector 14 is strictly perpendicular to the vertical direction and only reflects the wavelength of 632nm Light beams, light beams that transmit other wavelengths; the first reflector 13 is strictly perpendicular to the horizontal direction; the splitting ratio of the beam splitter 15 is 1:1, the beam s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com