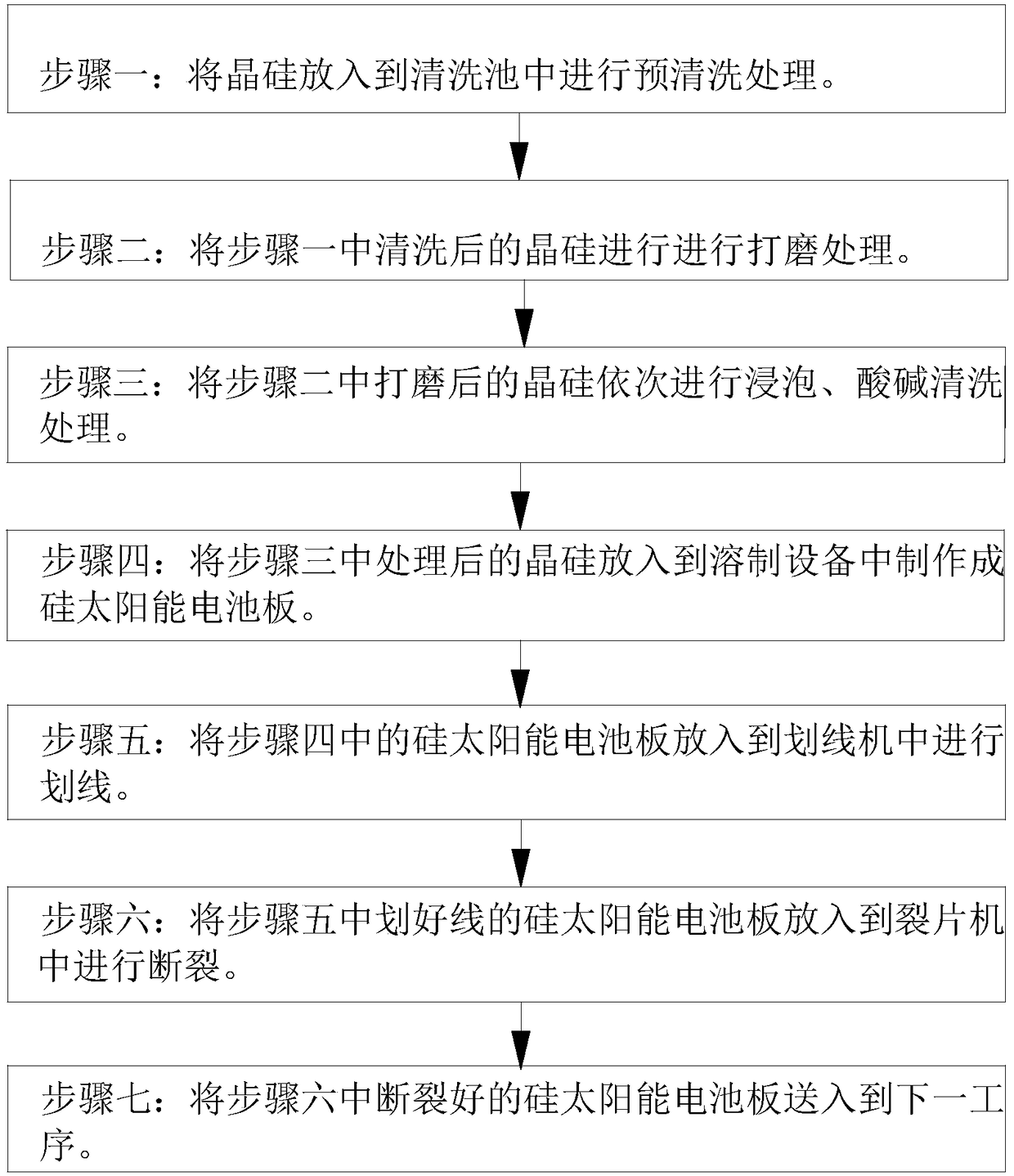

Silicon solar cell production process

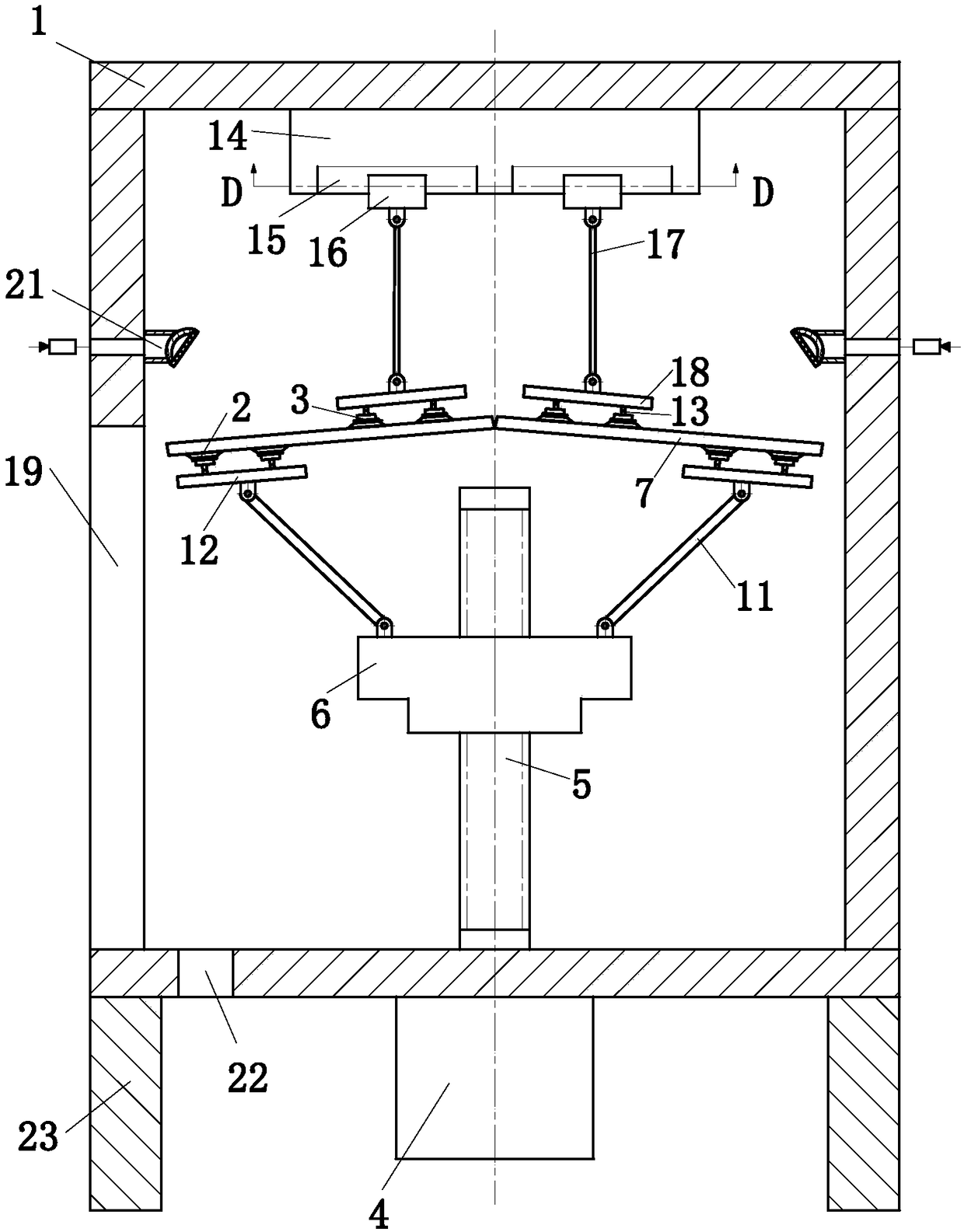

A silicon solar cell and production process technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of cumbersome operation, silicon solar cell panel breakage, etc., and achieve the goal of improving tight adsorption, improving fracture effect, and increasing adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

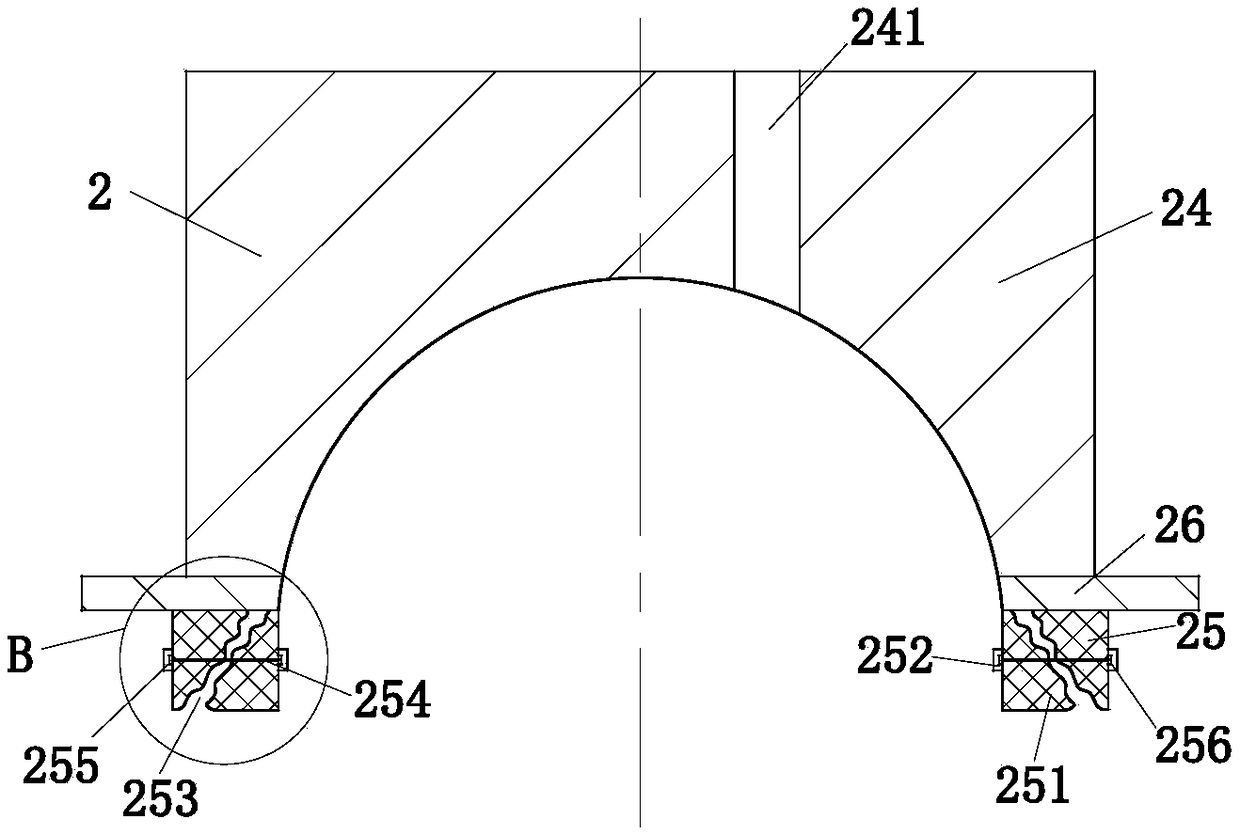

[0040] As an embodiment of the present invention, the No. 1 suction cup 2 includes a housing 24, a sealing unit 25, and a fixing ring 26; , so that the No. 1 suction cup 2 can closely contact the silicon solar cell panel 7; the fixing ring 26 is fixedly installed on the bottom of the housing 24, and the fixing ring 26 deforms the sealing unit 25 by squeezing the silicon solar cell panel 7 , improve the tight adsorption between the sealing unit 25 and the silicon solar cell panel 7, the sealing unit 25 is fixedly installed at the bottom of the fixing ring 26, and the sealing unit 25 is used for tightly adsorbing the silicon solar cell panel 7.

[0041] As an embodiment of the present invention, the sealing unit 25 includes a rubber ring 251 and a clamping part 252; the cross section of the rubber ring 251 is rectangular, and the rubber ring 251 is inclined to penetrate from the bottom of the rubber ring 251 to the rubber ring The annular groove 253 on the top of 251, the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com