Recovery method of lead-acid storage battery

A lead-acid battery, current technology, applied in secondary battery charging/discharging, secondary battery repair/maintenance, electrolyte/reactant regeneration, etc. rate, improved recovery, significant economic and environmental significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] The reasons for the reduction of battery capacity can be summarized as follows (without considering the physical damage of the battery): 1. The lead sulfate crystal is too large; 2. The sponge hole of the electrode plate is blocked; 3. The charging temperature is too high; 4. The electrolyte is missing.

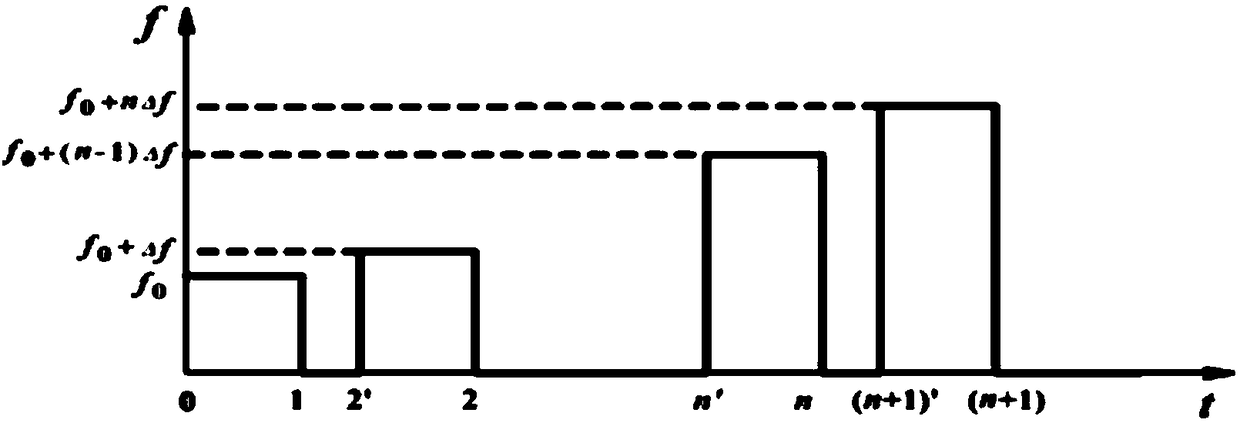

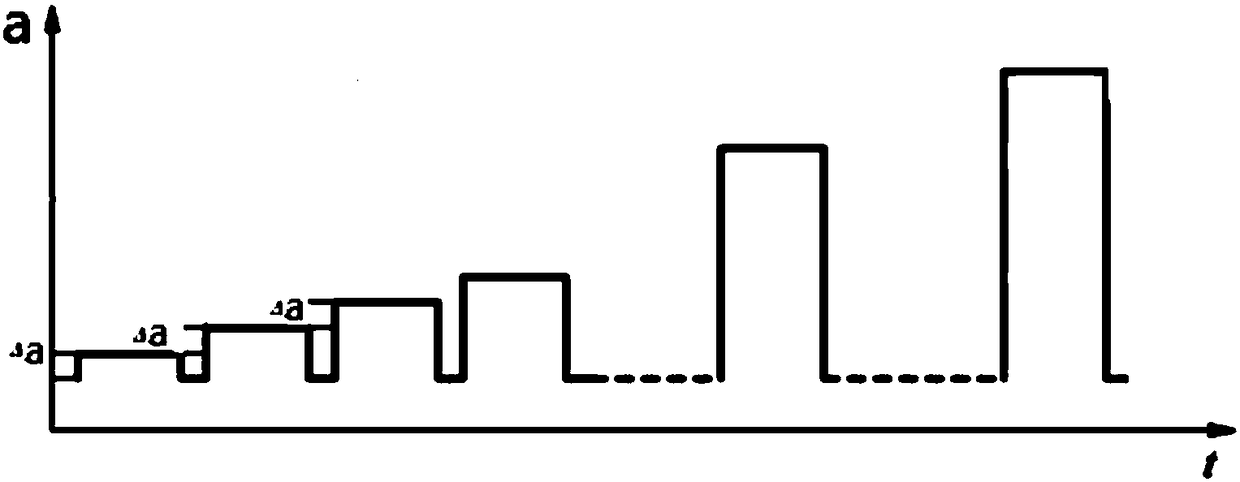

[0036]Based on the above situation, the present invention discloses an effective method for restoring a storage battery by combining repair fluid, ultrasonic cleaning and / or pulse charging.

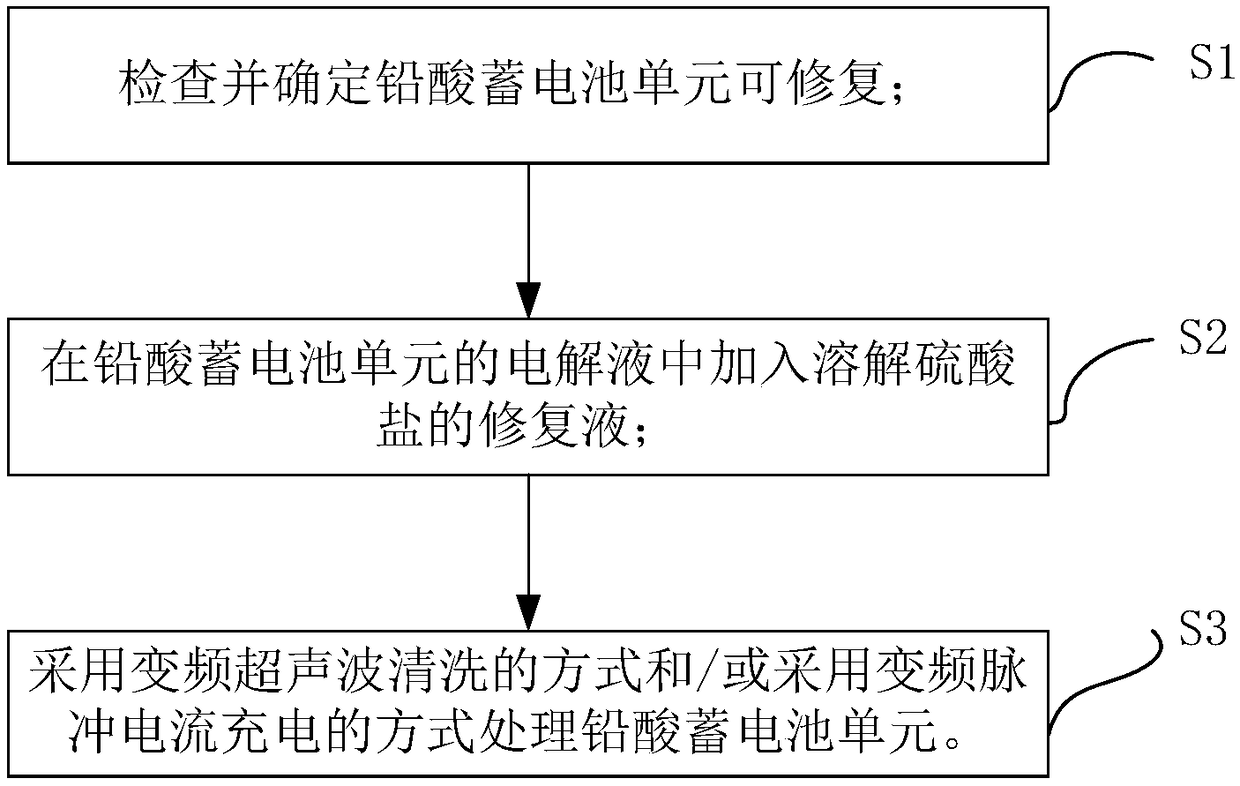

[0037] The recovery method of lead-acid storage battery of the present invention, comprises the following steps:

[0038] Step S1: Check and make sure that the lead-acid battery unit is repairable. Whether the lead-acid battery unit can be repaired can be determined by visual observation and / or instrument inspection. In appearance, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com