Novel brushless exciter rotor support assembly used for aircraft generator

A technology for rotor brackets and generators, which is applied to electric components, magnetic circuit rotating parts, electrical components, etc., can solve the problems of reducing the reliability of aviation generators and difficulty in heat dissipation, and achieves improved reliability, improved heat dissipation efficiency, and optimized The effect of the rotor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

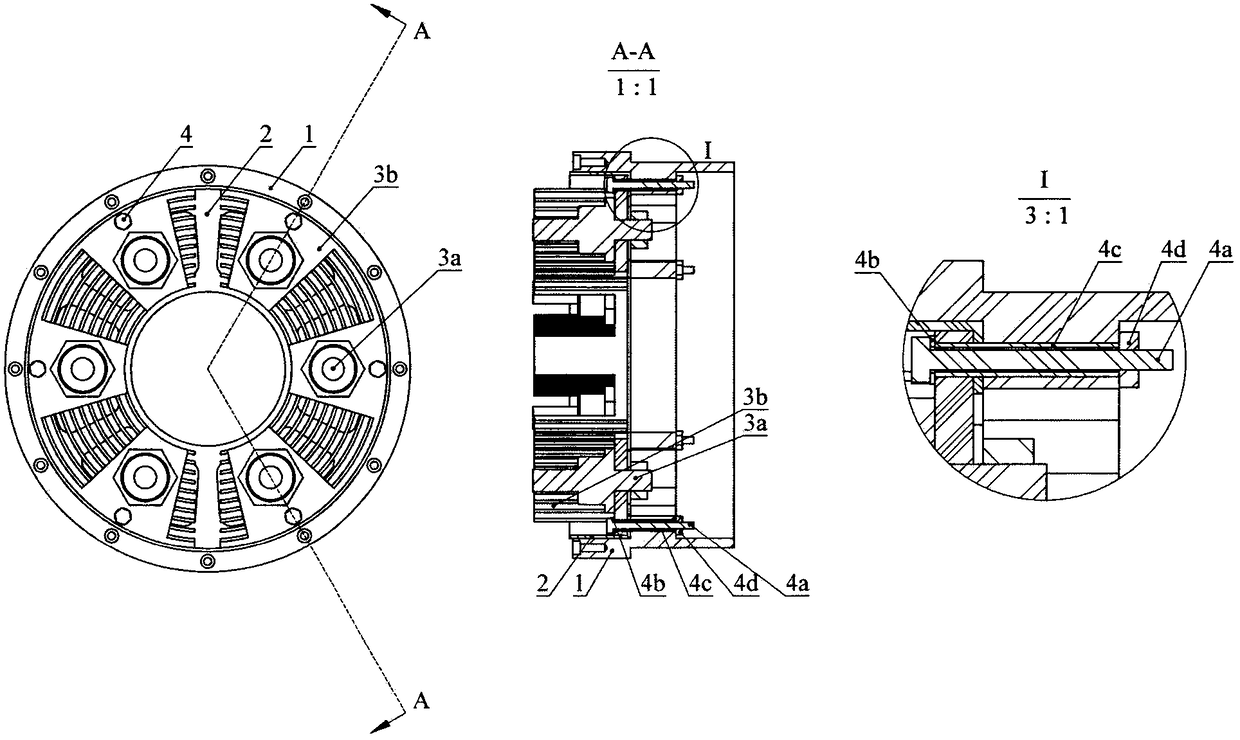

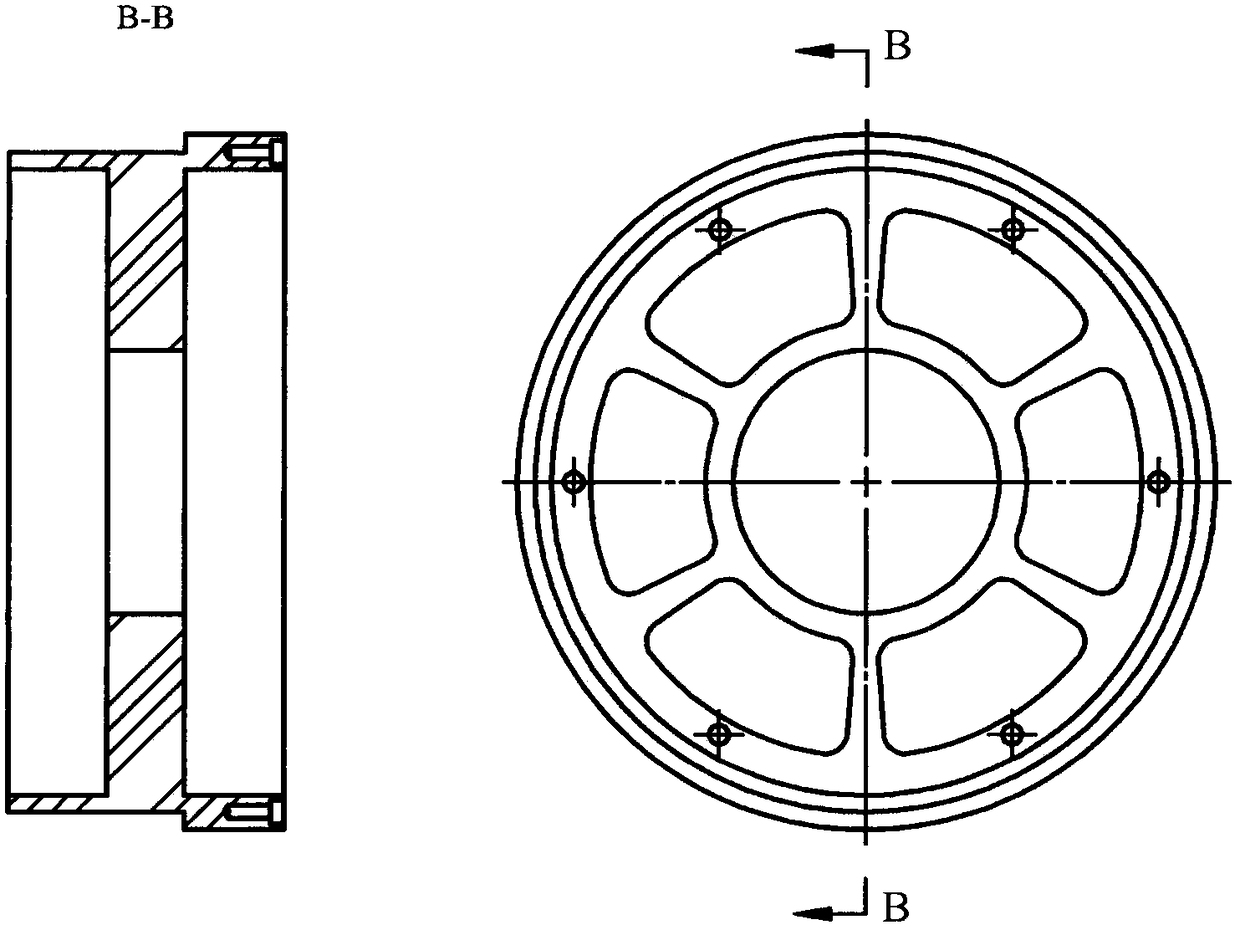

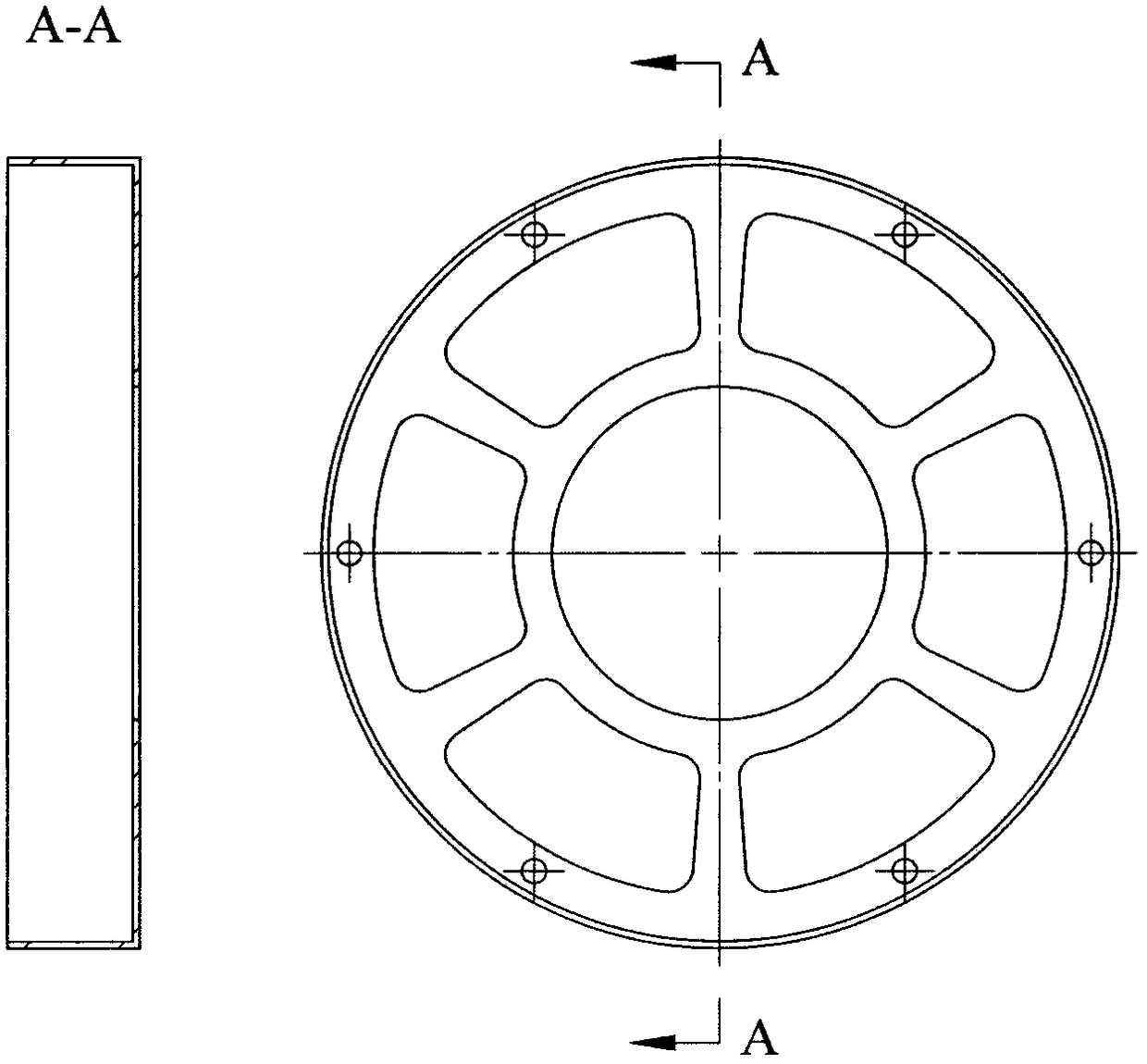

[0011] The present invention will be described in further detail below. see figure 1 , 2 , 3, 4, the rotor bracket assembly of the brushless exciter of the aviation generator, which is composed of the rotor bracket 1, the insulating plate 2, 2 rotating rectifier tube assemblies 3, and several fastener assemblies 4; the rotor bracket 1 is a hub-shaped The aluminum alloy bracket, the rotating rectifying assembly 3 is composed of three rotating rectifying tubes 3a and a rotating radiator 3b, each rotating rectifying tube 3a is fixed on the rotating radiator 3b by a nut, and the nut side is connected to the main generator DC, away from The side of the rotating radiator 3b is connected to the AC winding of the exciter, and the DC of the two rotating rectifier assemblies 3 are positive and negative respectively, and the fastener assembly 4 is composed of bolts 4a, insulating washers 4b, insulating sleeves 4c and nuts 4d; its features In that: said rotating radiator 3b is made of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com