Iridium plate as well as processing method thereof and iridium crucible

A crucible and rolling mill technology, applied in chemical instruments and methods, crystal growth, post-processing equipment, etc., can solve problems such as cracking, iridium crucible/product damage, and affecting the service life of iridium crucible/product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This example details the method for preparing the iridium plate of the present application. details as follows:

[0055] The first step: smelting iridium ingot, the iridium ingot can be 3-8 kg, specifically 6 kg in this embodiment.

[0056] The second step: put the iridium ingot in the first step into a high temperature furnace for heat preservation, the heat preservation time is 1 hour, and the temperature of the medium temperature furnace is 1300~1600 °C;

[0057] The third step: send the iridium ingot into the rolling mill along the long axis direction for rolling deformation, and the initial deformation is 15%;

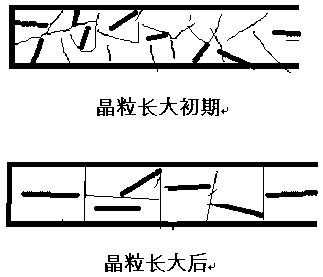

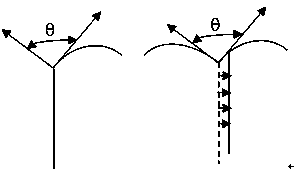

[0058] The fourth step: Send the iridium plate deformed in the third step into a special rolling mill for deformation. The deformation amount is 20%. The distance between the lowest points is 100~300 microns;

[0059] Step 5: Repeat step 4 until the thickness of the iridium plate is 2mm.

[0060] After the above steps, the iridium plate is obtained, whi...

Embodiment 2

[0062] The application also provides another method for preparing the iridium plate of the application, the method is as follows:

[0063] The first step: smelting iridium ingot, the iridium ingot can be 3-8 kg, specifically 6 kg in this embodiment.

[0064] The second step: put the iridium ingot in the first step into a high-temperature furnace for heat preservation, the heat preservation time is 1 hour, and the temperature of the heating furnace is 1300~1600°C;

[0065] Step 3: Send the iridium ingot into the rolling mill for repeated rolling and deformation until the thickness of the finished product is 1.3~1.4 times;

[0066] Step 4: Coat both sides of the iridium plate with zirconia, and the coating thickness is 100-300 microns;

[0067] Step 5: Send the iridium plate in step 4 into the rolling mill, the reduction in a single pass is 30~40%, and the finished product is rolled in one pass. The roll of the rolling mill can have a flat surface or a concave-convex surface; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com