System and method for eliminating cumulative errors of a crane

A technology of accumulating errors and cranes, which is applied in the testing of fluid pressure actuation systems, components of fluid pressure actuation systems, and mechanical equipment. , The effect of stable amplitude and good independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

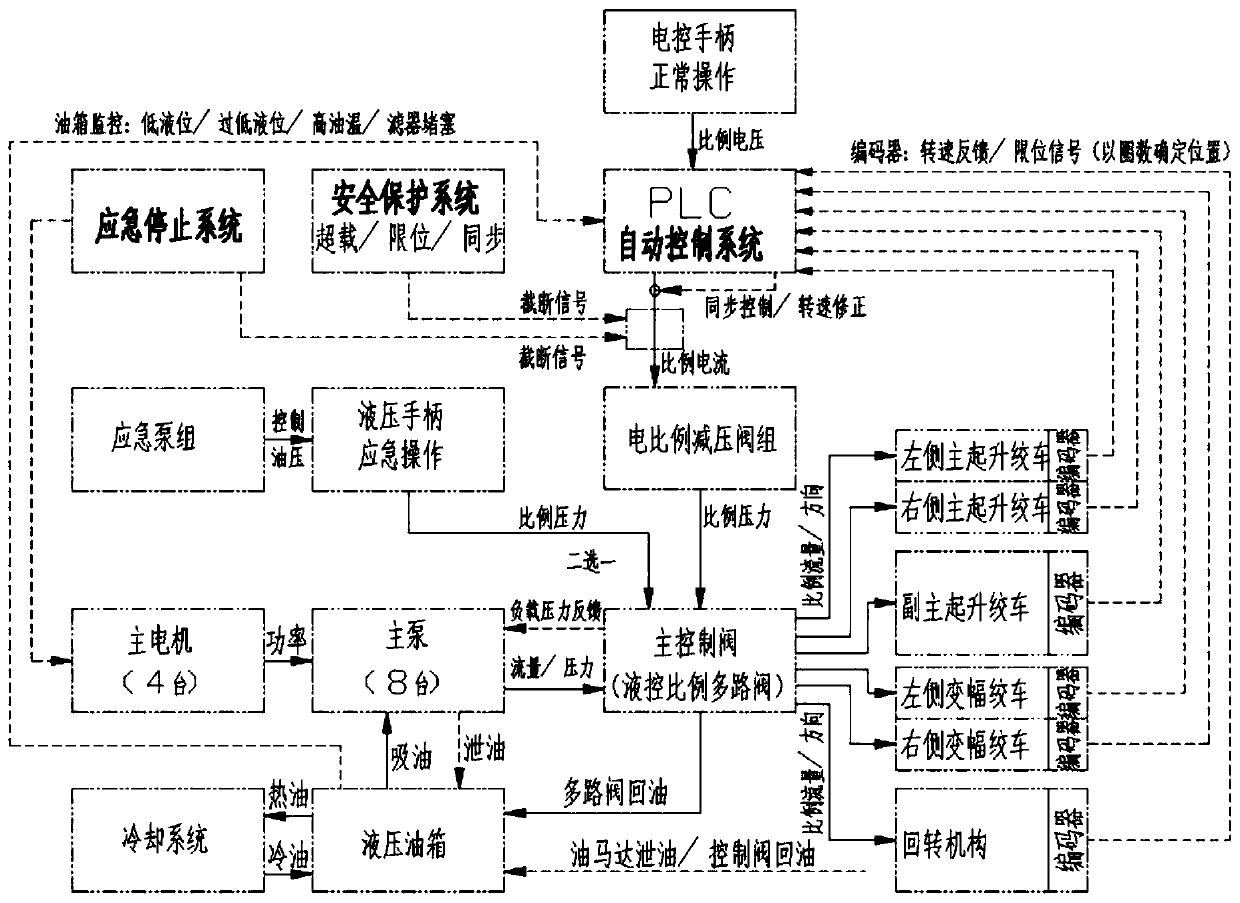

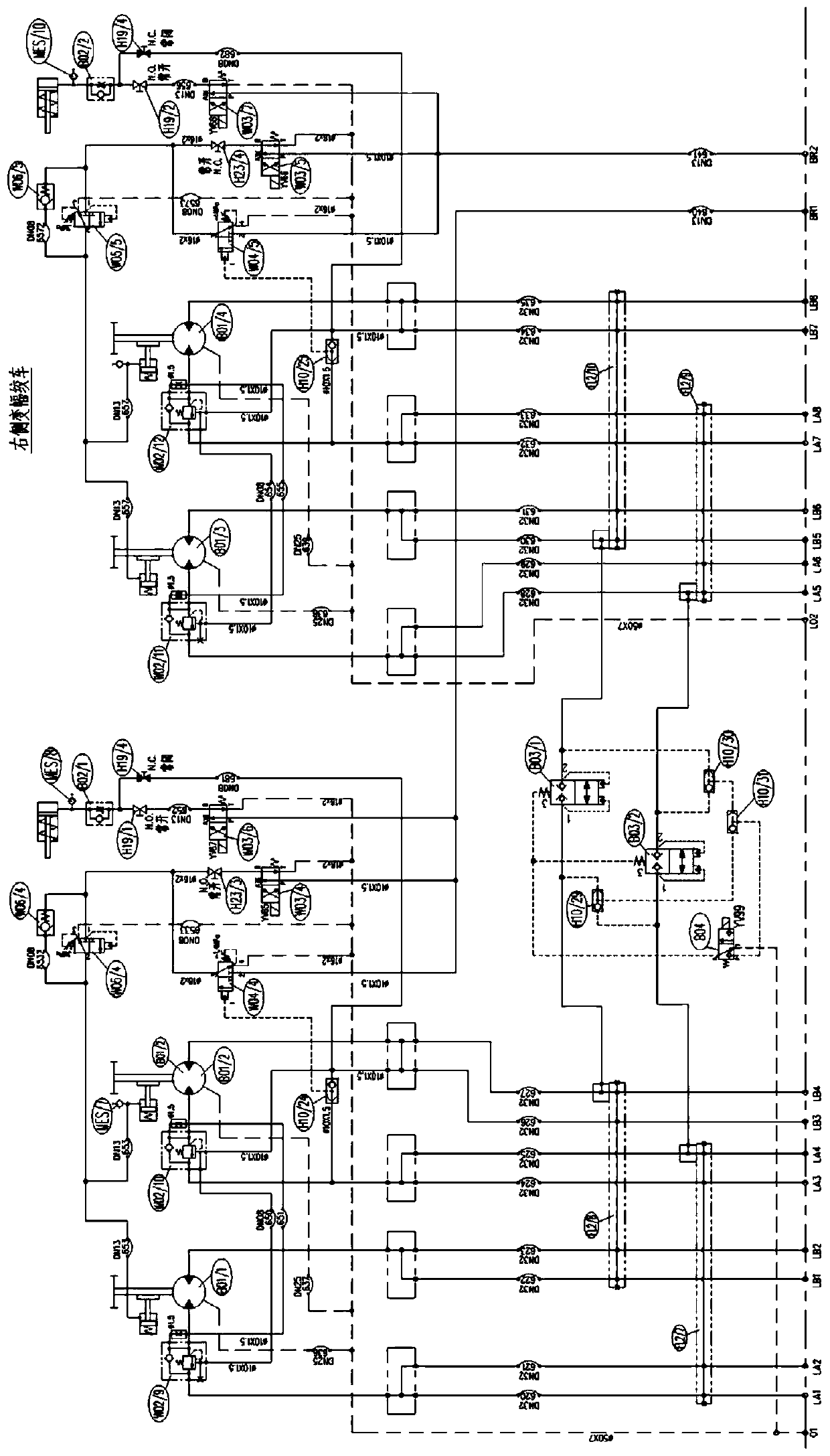

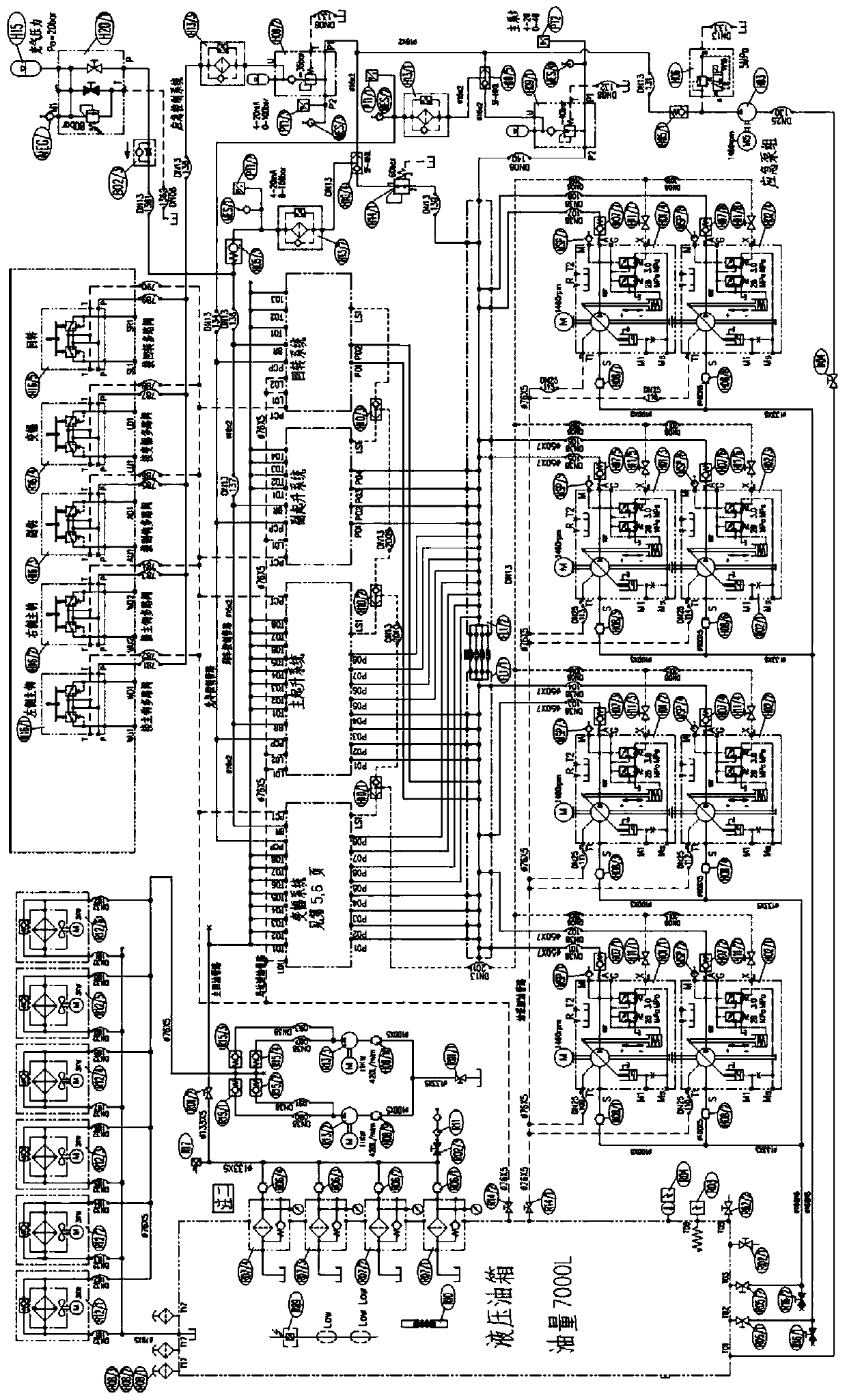

[0032] A crane, used for ships, includes a mechanical part and a control part. The mechanical parts are inserted into the legs on the main deck, the slewing mechanism set on the main deck and sleeved on the legs, the herringbone frame on the slewing mechanism, the jib hinged with the gable frame, the arm frame set on the arm The main hook, auxiliary hook, luffing hook under the top of the frame, the main hoisting winch used to drive the main hook, the auxiliary main hoisting winch used to drive the auxiliary hook and the hoisting winch used to drive the luffing hook Luffing winch. The slewing mechanism includes a slewing support device and a slewing platform arranged on the slewing support device; both the slewing support device and the slewing platform are set on the pile legs and do not contact with the pile legs, so the two do not interfere with each other, so that the slewing platform and the pile The legs are perfectly combined, saving the space occupied by the splint. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com