Lab organic waste liquid processing equipment

A technology for organic waste liquid and treatment equipment, which is applied in the fields of pathogenic microorganism wastewater treatment, sedimentation treatment, water/sewage treatment, etc. Simple manual operation and advanced design technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

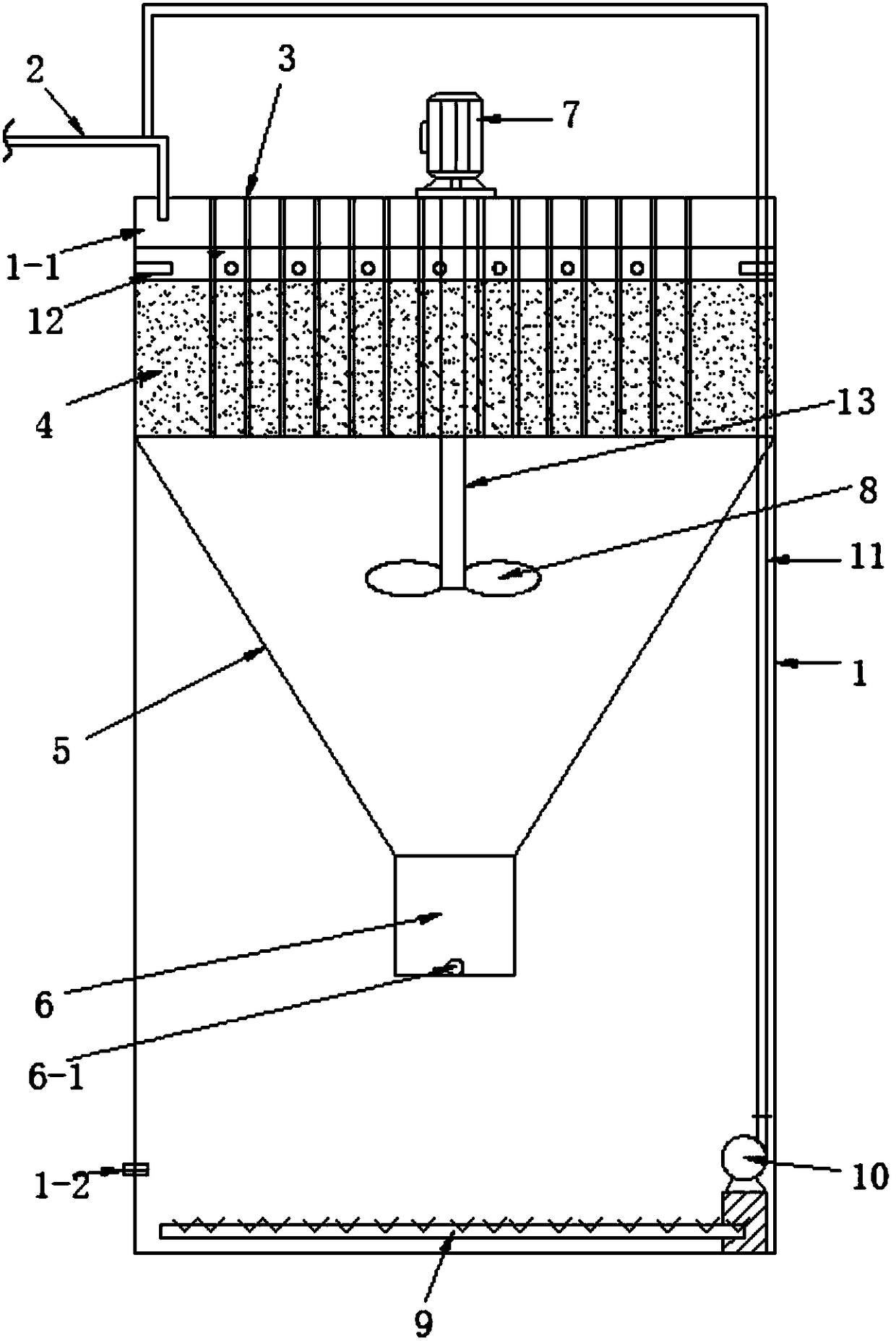

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

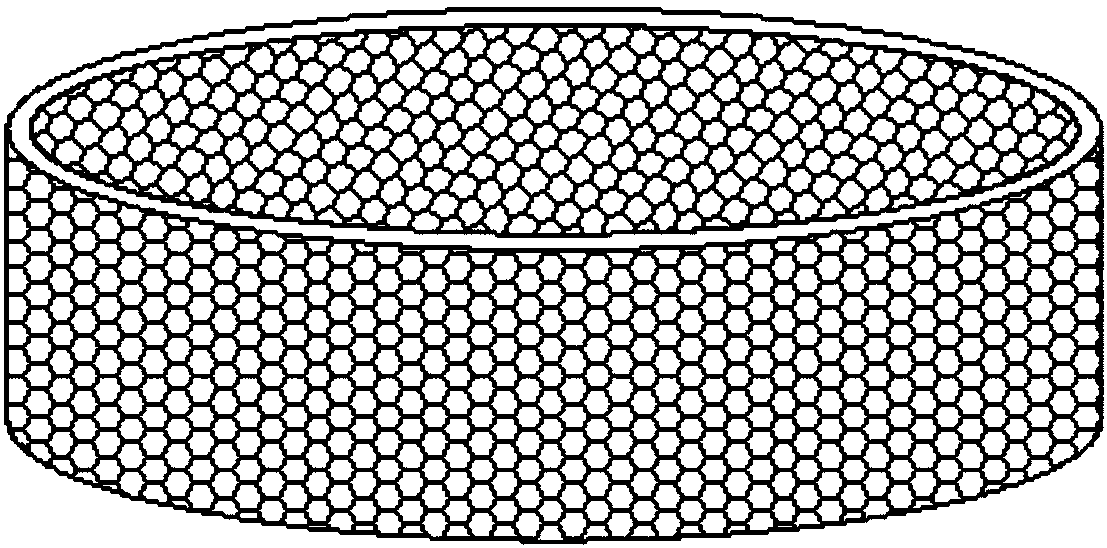

[0023] see as figure 1 and figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes the equipment main body 1, the water inlet pipe 2, the annular anode iron plate 3, the cathode filler 4, the conical porous filter plate 5, and the mud storage bucket 6; 1. The transparent structure is made of toughened glass. The inside of the equipment main body 1 is provided with a conical porous filter plate 5. The bottom of the filter plate 5 is integrally formed with a mud storage hopper 6, and the side wall of the mud storage hopper 6 is provided with a mud discharge port 6-1; the top of the mud storage hopper 6 is provided with a cathode filler 4, and the cathode filler 4 adopts porous The interior of the ceramic filler frame is filled with carbon particles, wherein the particle size of the carbon particles is larger than the aperture of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap