Method of detecting surface shape of reflection element based on dual-frequency orthogonal grating projection

A technology of orthogonal gratings and reflective elements, which is applied in the field of optical element plane detection, can solve the problems of complex process and time-consuming, and achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

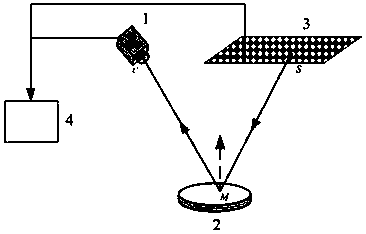

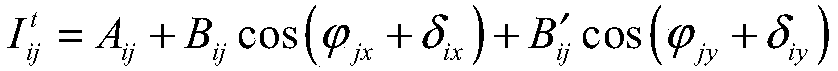

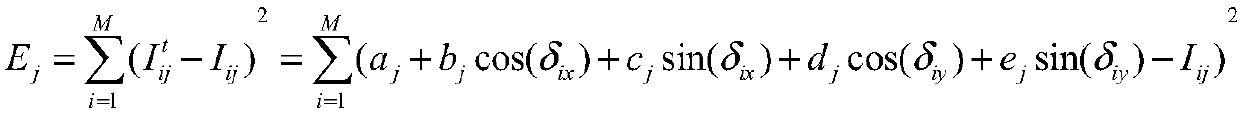

[0033] Please refer to figure 1 , the embodiment of the present invention provides a method for detecting the surface shape of a reflective element based on dual-frequency orthogonal grating projection. Its basic device This device includes a CCD sensor 1 , a component to be tested 2 , an LCD liquid crystal display 3 and a computer 4 . The LCD display 3 sequentially displays the dual-frequency orthogonal grating phase-shift fringe pattern generated by computer codes, and the CCD sensor 1 collects the deformed fringe pattern reflected by the surface of the component to be measured, and uses the least squares iterative algorithm to calculate the image collected by the CCD sensor 1 The position coordinates of the light source point on the display 3 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com