A closed-cavity PVDF film loudspeaker

A closed cavity and loudspeaker technology, applied in the direction of sensors, loudspeakers, electrical components, etc., can solve the problems of reducing the sound radiation of PVDF thin film loudspeakers, difficult driving of PVDF thin film loudspeakers, and noise pollution of loudspeakers, so as to improve noise pollution and increase sound quality. Pressure level, reduce the effect of sound radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

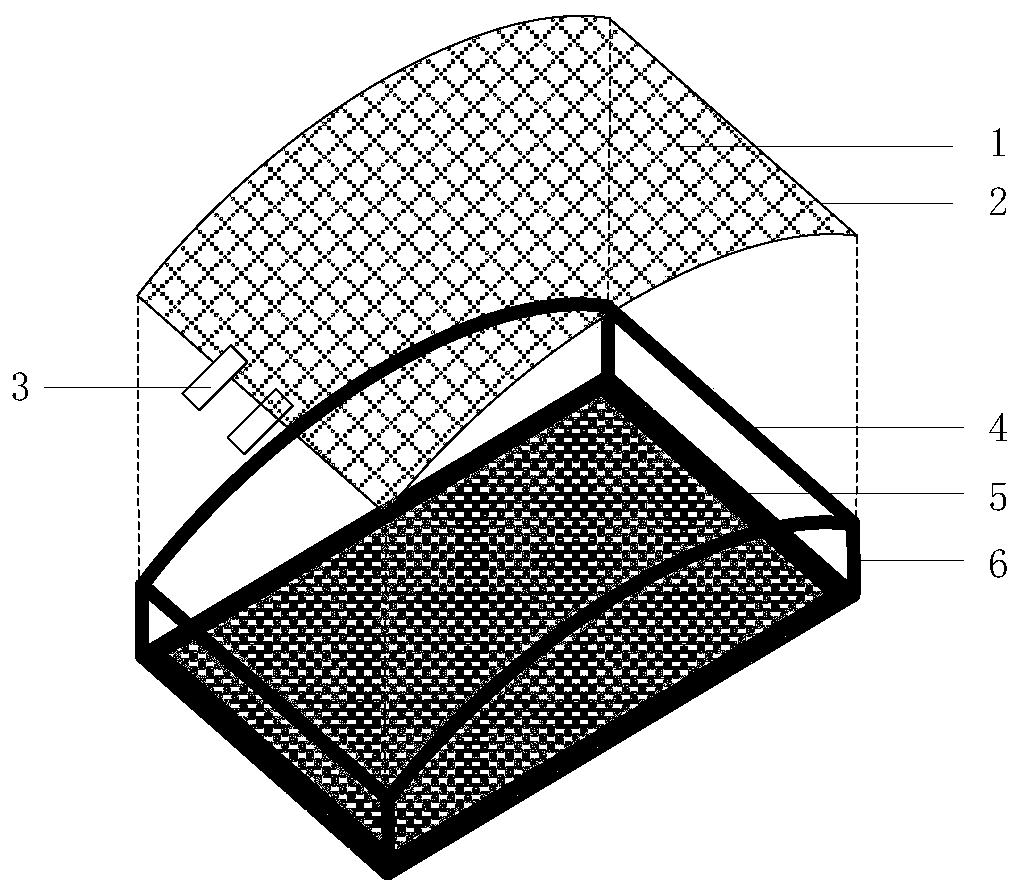

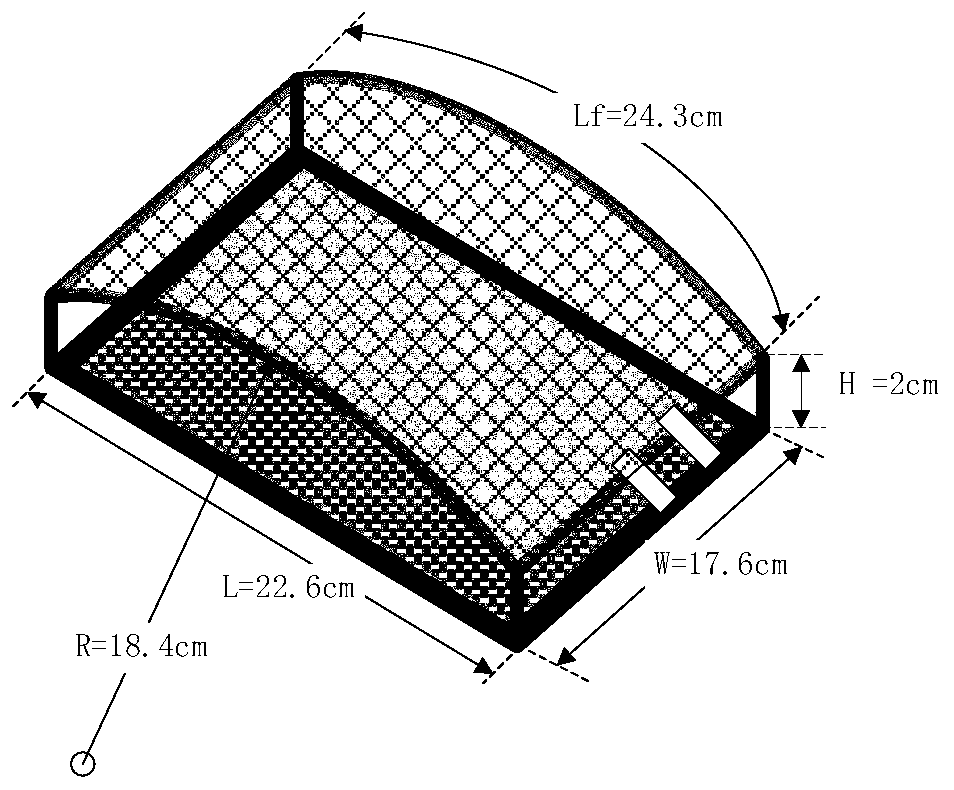

[0033] In the present invention, the main body structure of the closed-cavity PVDF film loudspeaker comprises: the packaged PVDF film (see figure 1 Part No. 2), sound-absorbing material layer (see figure 1 No. 5 part) and fiberglass back cavity (see figure 1 Part No. 6). The PVDF film has double-sided electrodes (see figure 1 Part No. 1 in the middle), and the double-sided electrodes respectively lead to external electrodes (see figure 1 Part No. 3 in the middle), part of the external electrode is exposed when the insulation package is carried out. A sealant is used between the PVDF film and the back cavity (see figure 1 Part No. 4) is glued firmly. The sound-absorbing material and the bottom of the back cavity are pasted with transparent double-sided ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com