Low-salt thick broad-bean sauce free from preservative addition, and production technology process of low-salt thick broad-bean sauce free from preservative addition

A preservative-free, salt bean paste technology, applied in food science, food preservation, food ingredients containing natural extracts, etc., can solve problems such as spoilage and deterioration, achieve delicious taste, high nutritional value, and ensure safety and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A low-salt bean paste without preservatives, the raw materials are prepared according to the following mass percentages: 15% broad beans, 60% fresh peppers, 5% edible salt, 3% wheat flour, 8% edible vegetable oil, 2% monosodium glutamate, 2% chicken essence, and spices 2% extract concentrate, 0.6% cumin powder, 0.6% pepper, 0.5% cinnamon powder, 0.5% rosemary powder, 0.5% star anise, 0.3% clove powder; the spice extract concentrate consists of cumin, pepper, Star anise, cinnamon, rosemary, and cloves are mixed in a weight ratio of 1:2:1:2:0.5:0.3, boiled in water five times the weight of spices, and concentrated to one third of the solution.

[0039] A production process for adding low-salt bean paste without preservatives is characterized in that it comprises the following steps:

[0040] S1. Raw material acceptance:

[0041] The raw and auxiliary materials to be accepted include: broad beans, fresh peppers, edible salt, wheat flour, edible vegetable oil, monosodium g...

Embodiment 2

[0063] No preservatives added low-salt bean paste, prepared according to the mass percentage of the following raw materials: 22% broad beans, 57% fresh peppers, 6% edible salt, 4% wheat flour, 5% edible vegetable oil, 1.5% monosodium glutamate, 1% chicken essence, Spice extract concentrate 1.5%, cumin powder 0.5%, pepper 0.5%, cinnamon powder 0.3%, rosemary powder 0.3%, star anise 0.3%, clove powder 0.1%. The spice extraction concentrate is mixed with fennel, Chinese prickly ash, star anise, cinnamon, rosemary, and cloves in a weight ratio of 1:2:1:2:0.5:0.3, boiled in water five times the weight of the spices, and the solution is concentrated to One-third made.

[0064] The specific production process is prepared according to the method of Example 1.

Embodiment 3

[0066] A low-salt bean paste without preservatives, the raw materials are prepared according to the following mass percentages: 24% broad beans, 58% fresh peppers, 4% edible salt, 6% wheat flour, 3% edible vegetable oil, 1% monosodium glutamate, 1.5% chicken essence, and spices 1.1% extract concentrate, 0.3% cumin powder, 0.3% pepper, 0.2% cinnamon powder, 0.2% rosemary powder, 0.2% star anise, 0.2% clove powder; the spice extract concentrate consists of cumin, pepper, Star anise, cinnamon, rosemary, and cloves are mixed in a weight ratio of 1:2:1:2:0.5:0.3, boiled in water five times the weight of spices, and concentrated to one third of the solution.

[0067] The specific production process is prepared according to the method of Example 1.

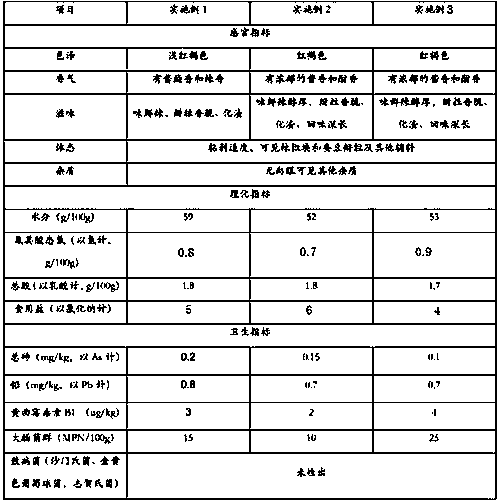

[0068] The characteristic of the bean paste that above-mentioned three embodiments prepare is as follows:

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com